Wärtsilä Water and Waste's Multi-Stage Flash (MSF) evaporator enables the potential of ultraclean water for Hydrogen / H2 production and P2X applications by producing high-quality distillate from sea water, brackish water, or industrial water.

This makes the MSF one of the most useful technologies for Hydrogen / H2 production and P2X applications.

The conductivity of this 'ultra clean water' is extremely low: less than 1.5 μS/cm.

A specific advantage of the multi-stage flash technology is that the heat consumption - or thermal efficiency - can continuously be adjusted to the set requirements of an application. The MSF is able to produce up to 1500 tons of distillate per day. The distillate's quality and quantity are not impacted by the uptake water temperature.

The MSF ultra clean water generator proves to be one of the most reliable low-maintenance seawater desalination plants in the world. It is the only evaporator technology that strictly separates heat transfer and evaporation, minimizing the risk of scaling and greatly reducing maintenance costs.

By leveraging ultraclean water for hydrogen production and P2X applications contribute to a cleaner, more sustainable future across various sectors, driving the transition towards a low-carbon economy.

KEY BENEFITS

TECHNICAL DATA

WORKING PRINCIPLE

MODELS

SCOPE OF SUPPLY

KEY BENEFITS

TECHNICAL DATA

Materials used

WORKING PRINCIPLE

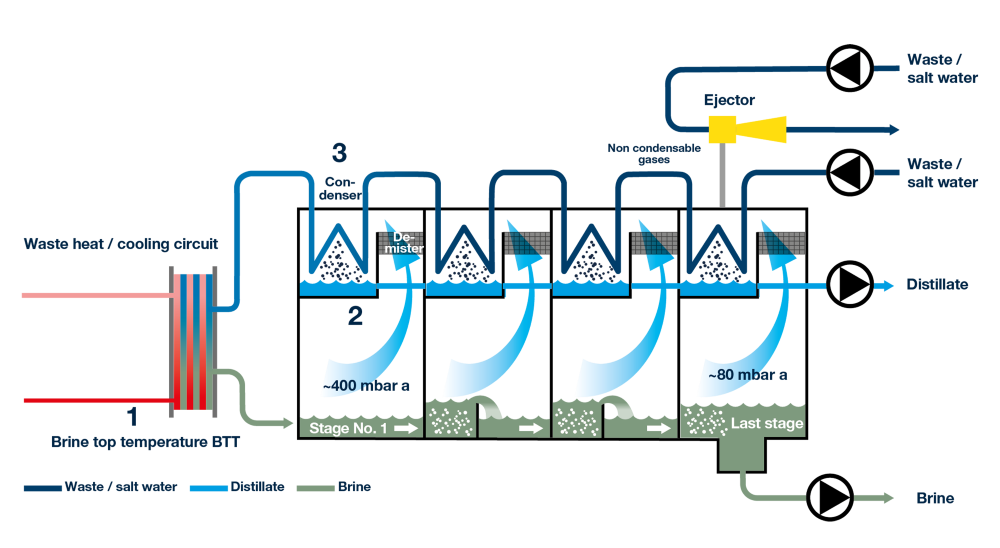

After leaving the first stage condenser (3), the seawater flows through the brine heater (1), where the heat input to the plant (steam or engine jacket water) causes a further temperature increase.

The seawater leaves the brine heater (1) and enters the first flash chamber (2), reaching a brine top temperature of approx. 80°C.

At this point the pressure of the incoming seawater is suddenly reduced, by means of an orifice, below its equilibrium vapour pressure resulting in explosive boiling or evaporation (flashing). The pure vapour produced is then condensed, giving up its latent heat to preheat the incoming seawater (3).

If this process is repeated over a large number of effects, at successively lower pressures and temperatures, large distillate production rates at reasonable performance ratios can be achieved.

MODELS

| System | Capacity (ton/day) | Power (kW) | Dry weight (kg) | Wet weight (kg) | Footprint (L x W x H, mm) |

|---|---|---|---|---|---|

| MSF 115-5 | 115 | 915 | 18000 | 21000 | 5700 x 2900 x 3000 |

| MSF 300-6 | 300 | 2388 | 27000 | 32000 | 7300 x 2900 x 3300 |

| MSF 650-6 | 650 | 5146 | 37000 | 45000 | 9200 x 3500 x 3900 |

| MSF 775-8 | 775 | 4812 | 42000 | 52000 | 10500 x 3600 x 3900 |

| MSF 850-8 | 850 | 4780 | 43000 | 53000 | 11700 x 4200 x 3900 |

| MSF 950-8 | 950 | 6395 | 45000 | 55000 | 12000 x 3700 x 3900 |

Capacity up to 1500 ton/day.

Steady production of freshwater at seawater temperatures 0 - 32ºC.

Water conductivity of distillate for all models: < 1.5 μS/cm.

SCOPE OF SUPPLY

Delivered as standard

Options

Wärtsilä Water & Waste

Freshwater Generators

Pankower Str. 16-18

21502 Geesthacht

Germany