Compliance with environmental regulations requiring effluent from cruise ships to be clean and safe can be a real challenge. Wärtsilä Water & Waste has a proven track record in developing technology to meet these anticipated environmental standards. Our solutions have now set the global benchmark for wastewater management. Wärtsilä can provide the cruise market with a complete, fully integrated, wet and dry waste treatment package.

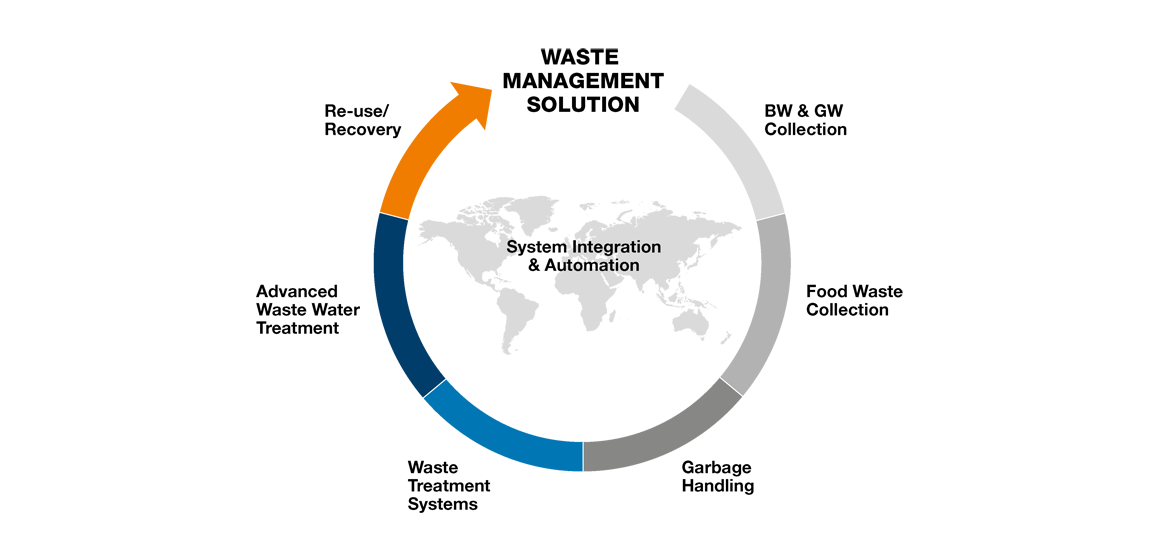

Due to the new demand from cruise yards for integrated waste treatment systems, Wärtsilä Water & Waste has developed a complete waste treatment package for ships where all systems are working together.

In practice, the new system of waste handling means better possibilities to reuse and recycle. Materials like metal and glass can now be collected separately inside the ship. Taken onshore when the ship comes to harbour, these materials can be transferred for recycling, and nothing goes to waste. The water is processed through a ‘grey and black water’ treatment system. The dried waste is handled together with bio-material and other burnable waste. It can be burned on-board in incinerators, which are also part of Wärtsilä’s waste-management system.

One of the benefits of a complete waste management solution is the footprint. On cruise ships, a surprisingly large amount of waste can build up in a short time. Before, the storing of the waste took a lot of space. But now, as the waste is largely managed on-board, there is less need to store it, therefore requiring less space on the ship. There are environmental benefits as well. The less energy the waste-management systems use, the less energy that needs to be produced. With total waste management the efficient process of collection, recycling and disposal in modern low-emission incinerators provides high efficiency, with the lowest impact on the environment.

| System benefits | Customer benefits |

|---|---|

| IMO certified | No compliance problems, future proof |

| Exceeds USCG, HELCOM and Alaska effluent discharge standards | Cruising with peace of mind. The system meets and exceeds the likely regulatory requirements for both new and existing installations |

| Simple design & operation compared to submerged membrane or hybrid systems | Save time with easy maintenance |

| Safe, reliable operation with no coagulation, flocculation, chemical oxidants, or pH neutralisation | Operational peace of mind, lower power consumption, and no system blocking |

| Compact design saving space and weight | Get more space for revenue generating areas such as cabins |

| Remote monitoring by specialists | Feeling secure, there is always an expert at hand |

| Totally integrated systems for wet and dry waste | No interface issues between wet and dry waste interface |

| Robust construction for long life and low maintenance | Lowest possible cost of ownership |

| Membrane integrity is visible and secured | Easily accessible when needed |

| No odour emissions due to biological process | More comfort for your personnel and passengers |

| Complete flexibility with newbuild, conversion and retrofit options | You can receive a complete total package according to your needs |

| One supplier, one complete system | One point of contact, easier communication |

Wärtsilä’s proven Waste Treatment Solution to support Carnival’s nine brands in their increased sustainability strategy

Wärtsilä’s Auto Gasification solution to provide sustainable waste disposal for Princess Cruises vessel

Wärtsilä enters dry waste treatment business for cruise ships

If you are in the cruise segment, working as an owner/operator or perhaps running a cruise yard, then there is a clear advantage in maintaining a more proactive public image. This can be achieved with a complete waste treatment package optimised for the cruise market.

Wärtsilä as a global group can contribute with worldwide support 24/7 as well as provide main engines, propulsion equipment and much more. The complete waste treatment package that your cruise ship needs is now available from Wärtsilä. Having only one supplier for the whole package reduces your technical and commercial risks. In addition, the compact size can increase the vessels revenue in terms of more cabin space.

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

For NEWBUILD & RETROFITS, please contact +44 1202 662 600 or waw.sales@wartsila.com

For spare parts, please e-mail us with the Equipment Serial Number or the name of the vessel at pse@wartsila.com. For urgent support, contact +44 1202 662 634.

For technical support & service, please email us with the Equipment Serial Number or the name of the vessel at poole.service@wartsila.com. For urgent support, contact +44 1202 662 616.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.