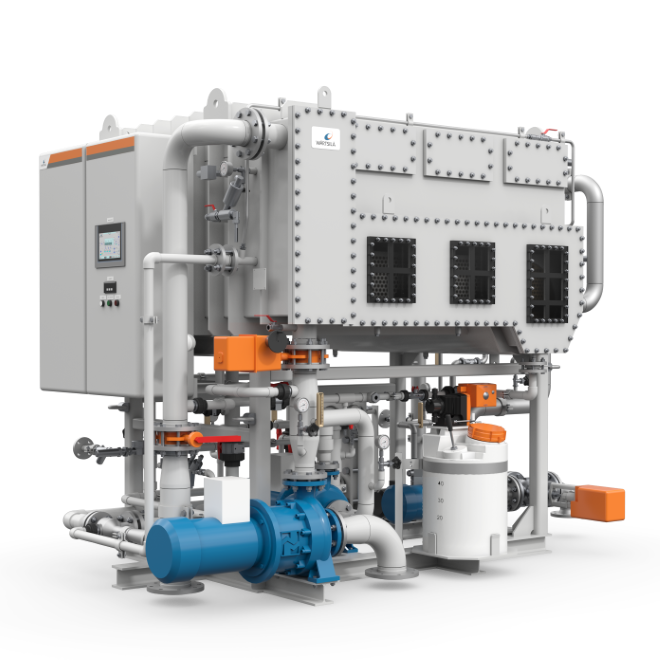

The Wärtsilä Horizontal inner Tube Evaporator (HiTE) is a multi-effect evaporator specifically designed for producing small to medium capacities of 30 to 175 tons of distillate per day. This marine freshwater generator guarantees potable water for human consumption and clean process water for technical applications. It serves in a wide range of operational areas where alternative technologies like reverse osmosis or plate technology reach their limits. Shallow waters with poor seawater quality is an example of this.

The HiTE operates smoothly even at partial load. For example during dynamic positioning (DP) operations. The unit’s control system can be fully or semi-automated. Its smart processes adapt automatically to the amount of energy available. The HiTE is able to use waste heat. This is very convenient for vessels with varying engine profiles. The 4-stage HiTE offers up to 75% energy savings with a specific heat consumption of 180 kWh/t compared to single stage designs (700 kWh/t). For a 3-stage HiTE this is 240 kWh/t.

Low operational cost | High reliability | 30 - 175 tons distillate per day | Uses waste heat from ships with varying engine profiles

The HiTE is able to utilise waste heat. This is very convenient for vessels with varying engine profiles.

KEY BENEFITS

TECHNICAL DATA

WORKING PRINCIPLE

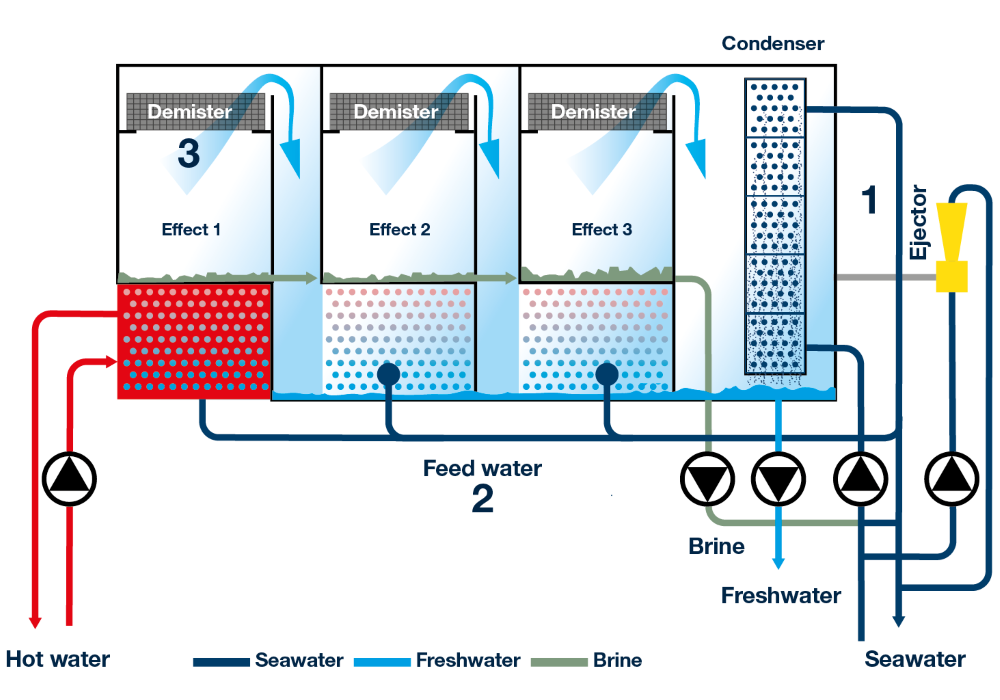

The HiTE freshwater generator consists of 3 film evaporators (connected in series) and one condenser (1). The seawater is passing through the condenser. The major portion – after being used as cooling medium – is flowing back to the sea. A certain (minor) quantity is distributed in three parallel streams (2) directly into the evaporators. The 1st effect is heated by hot engine cooling water. Before evaporation can start, the feed water entering evaporator effect one is heated inside the tubes up to the boiling temperature.

The released vapours (3) are separated from the water/vapour mixture and are entering the 2nd and possible 3rd effects as heating medium. The procedure of condensation/evaporation is repeated in the 2nd and 3rd effect before the residual vapours produced in the 3rd effect are entering the condenser.

The surplus brines are cascaded via syphon pipes from stage to stage, as well as the collected distillates. The distillate from the 3rd effect is flashing into the condenser hot well which also serves as distillate collecting tank. The distillate is pumped into the collecting tank.

MODELS

| System | Capacity (tons/day) | Specific thermal power (kWh/t) | Electrical power* (kWh) | Dry weight (kg) | Wet weight (kg) | L x W x H (mm) | Footprint (m2) |

|---|---|---|---|---|---|---|---|

| HiTE 30-3 | 30 | 240 | 5,9 | 2100 | 2415 | 1800x1500x2000 | 5,4 |

| HiTE 50-3 | 50 | 240 | 5,3 | 3500 | 4025 | 2300x2000x2000 | 9,2 |

| HiTE 80-3 | 80 | 240 | 4,2 | 5100 | 5865 | 2750x2000x2000 | 11,0 |

| HiTE 120-3 | 120 | 240 | 4,1 | 6500 | 7475 | 3250x2000x2000 | 14,0 |

| HiTE 120-4 | 120 | 195 | 3.2 | 7200 | 8280 | 3750x2000x2000 | 19,0 |

| HiTE 175-3 | 175 | 240 | 3,8 | 7500 | 8550 | 4250x2300x2200 | 21,5 |

| HiTE 175-4 | 175 | 195 | 2,9 | 8100 | 9315 | 4750x2300x2200 | 24,0 |

* Electrical power consumption can vary depending on conditions

Water conductivity of distillate for all models: < 4 μS/cm

Seawater inlet temperature: 0 – 35°C

Heating water inlet temperature from 70 – 90°C

Variants

Tandem ejector: without brine pump, but with higher electrical power

Heating water source: for all qualities of water between 70 °C and 95 °C, steam or a combination of both

Electrical control: PLC or manual control

SCOPE OF SUPPLY

Delivered as standard

Options

The Horizontal inner Tube Evaporator is predominantly known as a marine freshwater generator. It suites a wide range of vessel types such as chemical tankers, small cruise ships, ferries and special purpose vessels. Did you know that also offshore and land-based applications are equipped with HiTE's?

Unique Wärtsilä fresh water production system offers one ton per day fuel savings

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.