Freshwater generators / distillers

Freshwater generators - or distillers - are technical solutions that convert seawater, well or polluted industrial water into freshwater or 'distillate'. Distillate can directly be used as technical water. After additional miniralisation it is also usable for human consumption, as potable water, and for agricultural purposes, as irrigation water.

Freshwater distillers typically use a combination of heat and vacuum to vaporise feed water into a clean vapour. A condenser unit will then turn the water vapour back into a liquid phase of ultra clean permeate.

Ships and offshore installations typically use freshwater generators to obtain technical water for machine room operations, and potable water for on-board human consumption.

Land-based industries, including agriculture, use freshwater generators for various purposes:

- to re-use polluted industrial (effluent) water, minimising the amount of brine-for-disposal

- to generate freshwater from effluent or salty well water

- to cool down industrial processes, using the waste heat from these processes to obtain technical water

- to produce ultra clean water for Hydrogen / H2 production and other P2X applications

Technology choice for freshwater distillers

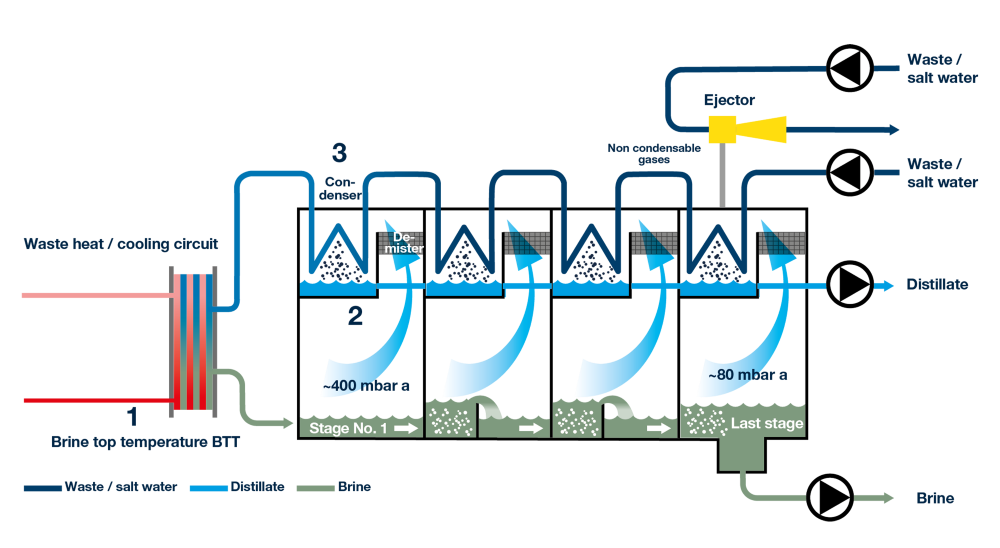

1. Multistage evaporator

A type of freshwater generator that uses multiple consecutive flash chambers, also referred to as ‘effects’. In each flash chamber feed water is brought to boiling or evaporation point, also called ‘flashings’. The produced distillate has a very low conductivity.

In a multistage ‘flash’ or evaporation approach, heat transfer and evaporation are strictly separated. This minimises the risk of scaling.

Heat consumption and thermal efficiency can be adjusted to the requirements of the application.

More on multi stage evaporators.

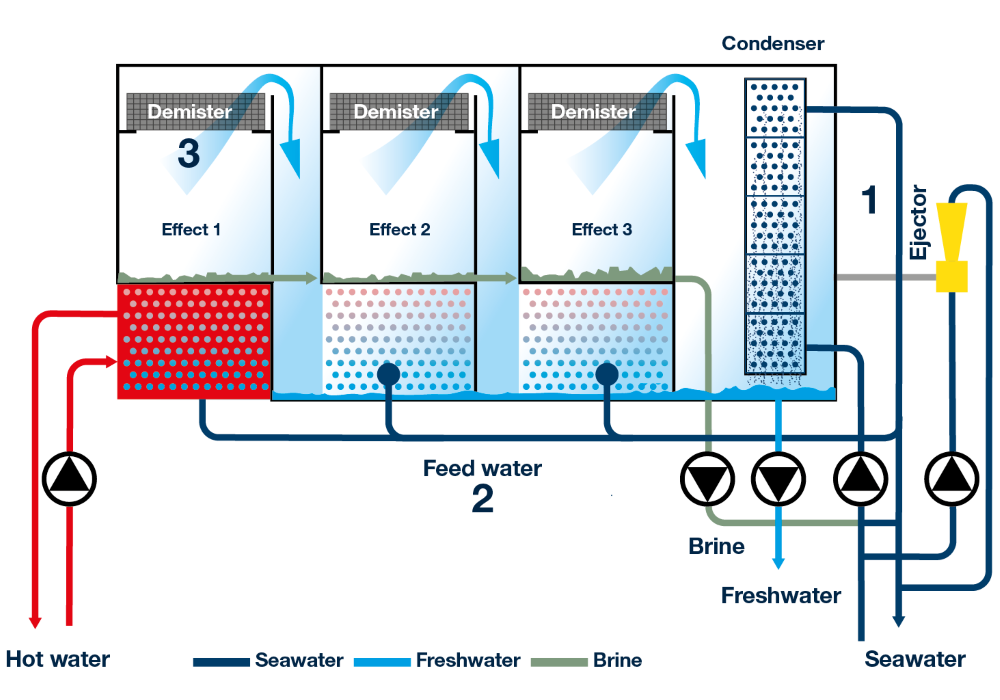

2. Tube evaporator

A type of multi-stage evaporator that uses a set of horizontally placed tubes to bring feed water up to boiling temperature. This approach eliminates scaling and allows processing very polluted feedwater from e.g. shallow coastal areas and river mouths.

More on tube style evaporators

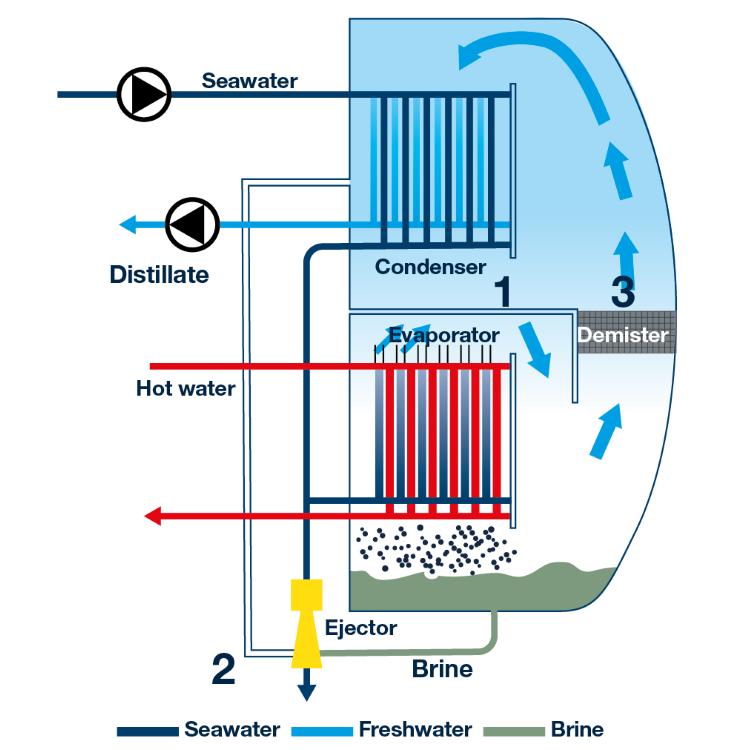

3. Single stage evaporator/distiller

Single stage freshwater generator using one chamber for vacuum distillation to remove salt and other impurities from (sea)water, converting it into freshwater. Waste heat from e.g. engines and steam can be used in the evaporation process. A single stage distiller does not require special consumables.

More on single stage distillers

Related: Reverse Osmosis freshwater makers