Wärtsilä's Membrane Bio Reactor (MBR) technology is based on biological degradation and membrane separation and allows for the treatment of grey and black water to satisfy the most stringent standards.

The process produces the highest quality discharge without requiring any addition or generation of chemicals that are hazardous to the environment or ship operation.

Effluent quality tests conducted by the US National Sanitary Foundation on Wärtsilä’s Membrane Bio Reactor produced results exceeding the most stringent future legislative pollutant standards envisaged. The technology also achieved outstanding performance in Alaska under the scrutiny of the local authority, USCG and USEPA studies over the past seasons.

We also supply smaller, more compact versions of our MBR systems. Wärtsilä Water & Waste mini-MBRs are ideal for use on smaller cruise and naval vessels, ferries with up to a 200 complement, as well as FPSOs and accommodation platforms.

KEY BENEFITS

FLUX DEVELOPMENT

OPERATION

EXTERNAL MEMBRANES

KEY BENEFITS

| Membrane Bio Reactor system benefits | Customer benefits |

|---|---|

| IMO certified | No compliance problems, future proof |

| Exceeds USCG, HELCOM and Alaska effluent discharge standards | Cruising with peace of mind. The system meets and exceeds the likely regulatory requirements for both new and existing installations |

| Simple design & operation compared to submerged membrane or hybrid systems | Save time with easy maintenance |

| Safe, reliable operation with no coagulation, flocculation, chemical oxidants, or pH neutralisation | Operational peace of mind, lower power consumption, and no system blocking |

| Compact design saving space and weight | Get more space for revenue generating areas such as cabins |

| Remote monitoring by specialists | Feeling secure, there is always an expert at hand |

| Totally integrated systems for wet and dry waste | No interface issues between wet and dry waste interface |

| Robust construction for long life and low maintenance | Lowest possible cost of ownership |

| Membrane integrity is visible and secured | Easily accessible when needed |

| No odour emissions due to biological process | More comfort for your personnel and passengers |

| Complete flexibility with newbuild, conversion and retrofit options | You can receive a complete total package according to your needs |

| One supplier, one complete system | One point of contact, easier communication |

FLUX DEVELOPMENT

Technology with membranes is developing rapidly. In the 2010 design, flux rates were averaging 20m3/day. In 2015, flux rates improved to 30m3/day. In 2016, the flux rates improved to 50m3/day. An increased flux of 50% decreases up to 50 % of the power requirement, as well as the ability to reduce the number of membranes required.

OPERATION

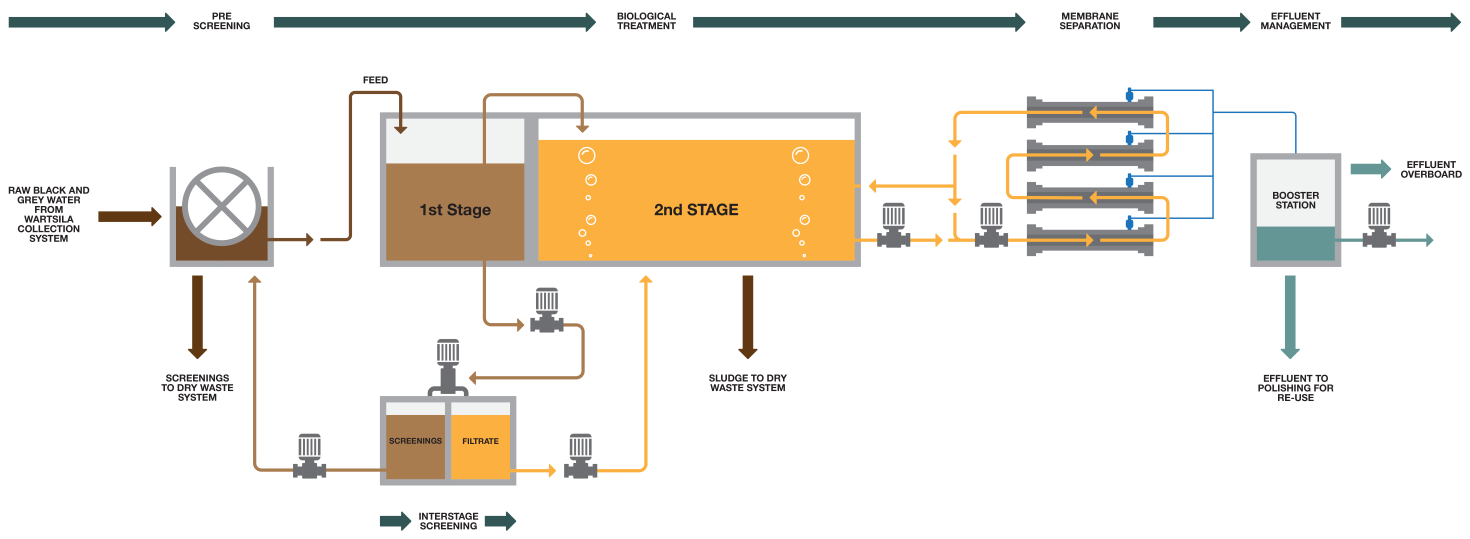

Black and grey water passes through the fine automatic pre-screen into the bioreactor where the active biomass degrades the organic material. Biomass is circulated through ultrafiltration membrane modules to produce a trans-membrane pressure and scouring velocity. Clean permeate is drawn from the membrane modules. The concentrated biomass is returned to the second stage bioreactor for discharge. Full automation delivers maximum efficiency and minimum man-hour input.

EXTERNAL MEMBRANES

Wärtsilä Water & Waste’s innovative advanced wastewater treatment technology, with external membrane separation, is based on biological degradation that allows for the high purity treatment of black and grey water to satisfy even the most stringent of standards. The latest system optimisation has achieved over 25% savings on energy consumption plus consumables and more than a 50% reduction in operational man-hours.

Please fill in the form, we aim to respond within 1-2 business days depending on the enquiry. For an existing installation, provide all necessary details to identify the installation and the equipment. Fields indicated with an asterisk (*) are required.

For NEWBUILD & RETROFITS, please contact +44 1202 662 600 or waw.sales@wartsila.com

For spare parts, please e-mail us with the Equipment Serial Number or the name of the vessel at pse@wartsila.com. For urgent support, contact +44 1202 662 634.

For technical support & service, please email us with the Equipment Serial Number or the name of the vessel at poole.service@wartsila.com. For urgent support, contact +44 1202 662 616.

Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.