THE RIGHT BWMS FOR EACH SHIP

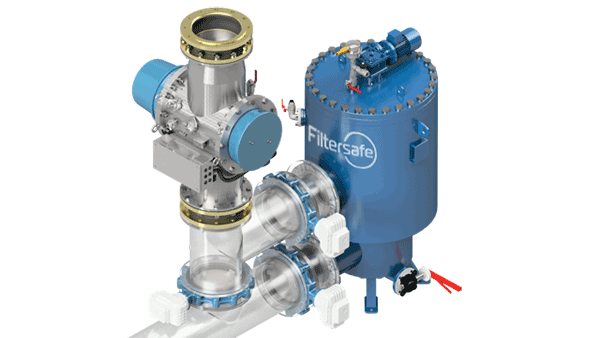

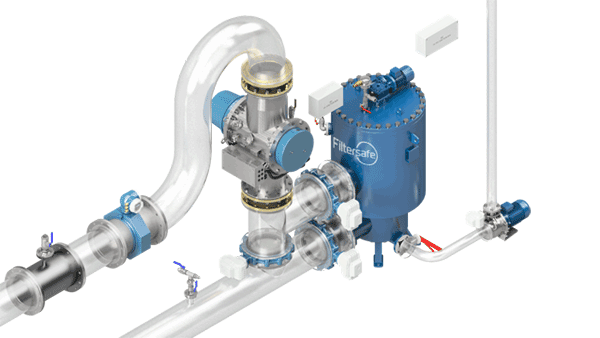

Proper filtration is the key to UV ballast water treatment. Aquarius has always been fitted with industry leading Filtersafe® filters and we are excited to be the primary launch partner for their latest development: the Manta filter. Manta takes ballast water filtration to the next level by pairing the cleaning efficiency of nozzleX™ with the removal efficiency of smartweave™ and taking the entire package down to 25 microns of organism-stopping filtration. Together with the newly designed OneMotion™ cleaning design, the Manta sets new a new bar for efficiency, size, and simplicity.

Water enters the vessel through the seachest and is pumped by the ballast pump to the first stage of the treatment system, the filter. At the filter, the water is first prefiltered to remove large particles and debris. The particles less than 1mm then enter the filtration chamber where they pass from the inside of the screen out to the filter body.

After filtration, the seawater is ready to go to the secondary stage to be treated before filling the ballast tanks.

As the water passes through the filter, organisms and dirt are trapped on the inside of the screen. A differential pressure sensor measures the amount of debris trapped on the screen and triggers the automatic self-cleaning cycle when the screen needs cleaning. During the self-cleaning cycle, the organisms and dirt on the screen are suctioned by the nozzles back through the scanner arm and deposited by the flushing system overboard.

After cleaning, the differential pressure returns to normal and the automatic cleaning cycle resets until the next time the screen needs to be cleaned.