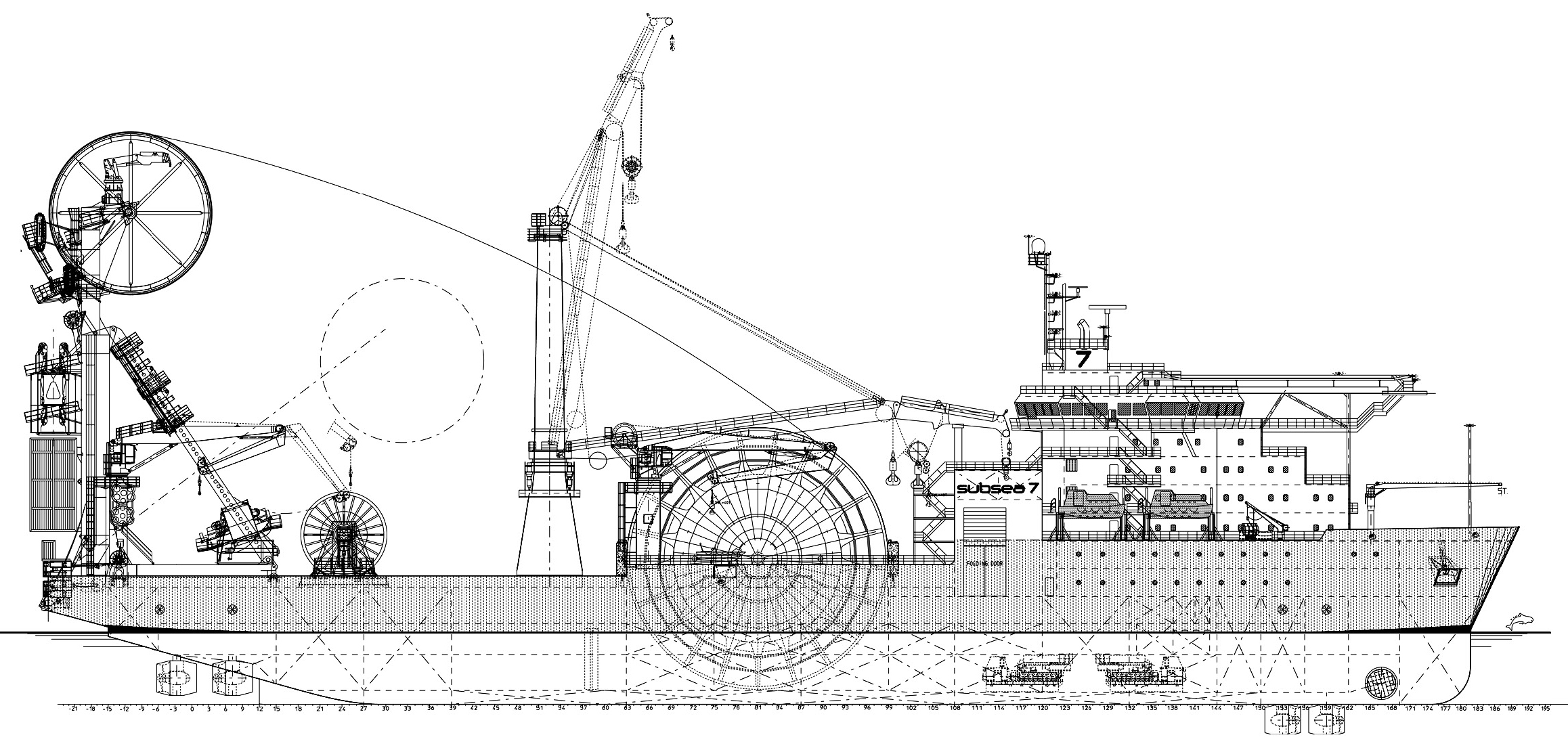

Rigid pipelaying vessel SEVEN OCEANS

According to HSB International June 2007

Built at the Merwede Shipyard in Netherlands, the SEVEN OCEANS is intended for installation of rigid pipes up to a diameter of 16’’ on the ocean floor in depths up to 3000m using the reel-lay method. It is the fastest method for installing oil pipelines on the seabed: because the lengths of pipeline are already welded together on shore, the vessel can continue to sail while the pipelaying is in progress. With an installing speed of 35 metres per minute, 100 kilometres of steel can installed on the seabed in just two days. The ship can deploy two remote operated vehicles which can monitor the pipelaying activities. Besides pure pipelaying, the ship can be used for subsea construction, ROV support and survey activities.

Centrally in the ship, there is a large reel for the storage of the rigid pipe. In a typical loading scenario, the ship will anchor herself with her stern facing the shore. The pipe can then be reeled-in from a production facility on shore, almost eliminating the need to weld or coat pipes in the difficult conditions of-shore.

The pipelaying activities are mostly concentrated on a 47.5m-high tower on the aft deck called the “lay ramp”. At the top of the tower there is an 18m diameter wheel, called the “aligner wheel”. Just below the wheel is the “straightener”. This device is composed of four caterpillar tracks which straighten the pipe. Below the straightener there is the so-called “Solex-drive” which can move the pipe up and down along the aft tower. Finally, the tensioner can provide a pull onto the pipe of up to 400t. This is necessary to compensate the force of the rigid pipe on the reel and to pull the pipe off the reel. The entire tower can be titled forward from the vertical position through 45 degrees. The angle is adjusted to the water depth and the characteristics of the pipe to be laid.

The ramp can also be moved 5m either side of the vessel’s centreline, to port or starboard, to minimise the fleeting angle between the ramp and the main reel. The entire assembly of the tower is mounted on a skid frame, which in turn is mounted on a pair of very heavily constructed transverse skid beams.

The SEVEN OCEAN is equipped with two ROVs stored in a large hangar at the aft side of the superstructure. Each ROV fits into a protective basket, which can be brought to the ship’s side through an overhead beam crane. The basket can then be lowered into the water along tracks on the ship’s side, acting as an “outboard elevator”. This way the ROV is brought through the “splash zone” in a controlled manner, after which the ROV can be manoeuvred out of its basket.

The vessel can also be used to install large subsea manifolds on the ocean floor. The main crane onboard is located on the portside and has a SWL of 400t at 16.5m. It is equipped with a heave compensator. A smaller knuckle boom crane on starboard has a SWL of 40t, while another one mounted to the aft deck tower can lift 12t at a distance of 25m.

A diesel-electric propulsion and energy arrangement is fitted, contained in two separate engine rooms, three propulsion, and two switchboard rooms. This is centred upon six Wärtsilä generating sets with 7L32 main engines driving 3600kVA alternators. These power three 2950kW azimuthing thrusters aft, two 2400kW retractable azimuthing thrusters and one 2200kw tunnel thrusters forward, plus the pipelaying equipment and shipboard facilities. The thrusters are all FP type, supplied by Wärtsilä Lips.

Length, oa: 157.31, Length, bp: 138.22m, Beam, mld: 28.4m, Depth, mld to the main deck: 12.5m, Design draught: 7.5m, Deadweight, design: 11,134dwt, Output: 20,160kW, Main propulsors: 2x2950kW azimuthing thrusters + 2x2400kW retractable bow thrusters, Trial speed with three thrusters: 14.5 knots.