When it comes to vessel design and optimisation, computational fluid dynamics (CFD) can be game changing. How much do you know about this fascinating technology? Here are six helpful facts that might surprise you.

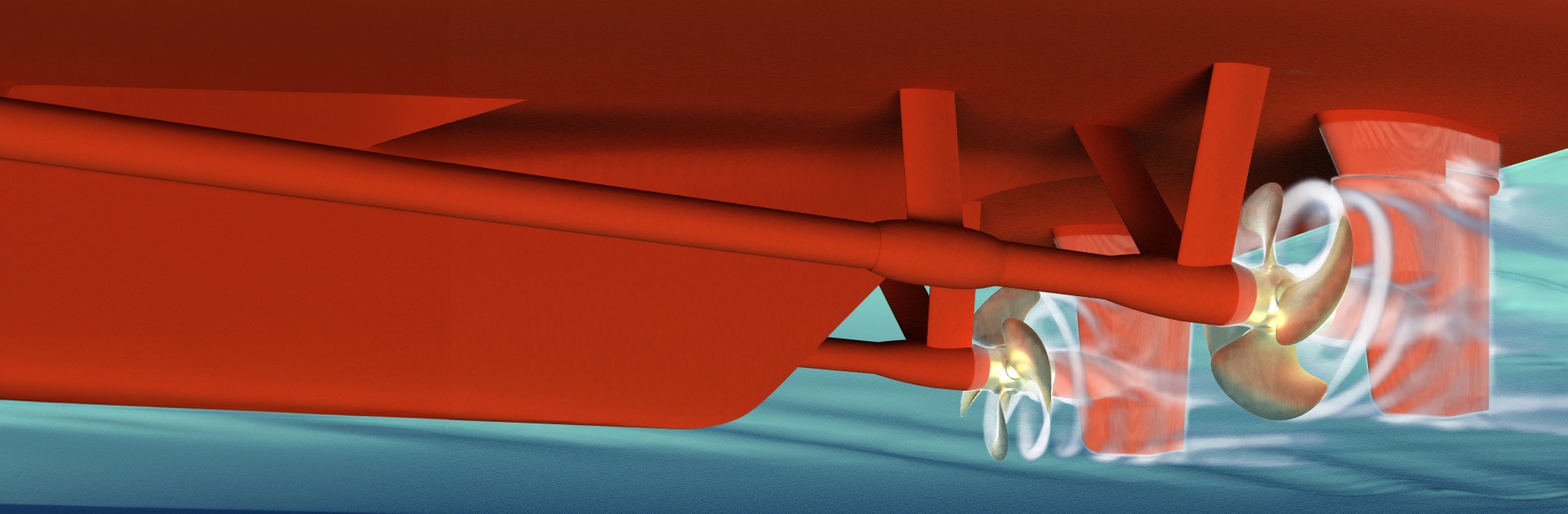

CFD uses advanced computational power to predict how water will flow in and around ship components. By analysing how individual components work together in the water, experts can achieve significant savings in energy efficiency.

Using CFD helps to:

- optimise vessel performance

- increase efficiency

- troubleshoot design problems – and much more.

Norbert Bulten, Senior Product Performance Manager, is a CFD veteran. He has been working with CFD at Wärtsilä since the discipline was in its infancy – and he’s full of helpful facts about CFD that could benefit any vessel. Here are just six that may surprise you, all gained from Norbert’s decades of work in the field.

Fact 1: CFD makes it possible to perfect a design in hours instead of days

Before CFD, designing a component like a ship’s propeller took a long time and was very expensive. The only way to reveal how water flowed around your propeller was to build a model and test it in a tank. If your design wasn’t exactly right, it was back to the drawing board and then back to the tank for testing.

With CFD, the designer simply inputs the propeller geometry into the CFD software and the performance curve is ready in one or two hours. The designer can run CFD for 10 or 20 variants, then use this information to squeeze every last percentage of performance gain. This also means optimisation can happen in the early design phases – when the real difference can be made.

Together, the marginal percentage point gains made possible by CFD add up to big savings in fuel and emissions. See what savings a gain of even two or three percent can make in this Insights article: One simple secret that will make your emissions reduction strategy look awesome.

The same principle applies when looking at the design of a whole ship rather than an individual component or system. With OPTI-Design, for example, designers take every aspect into account – including energy-saving technologies and other efficiency-boosting solutions – to push the limits of what’s possible.

“Finding the perfect balance of low noise, comfort and high efficiency would be impossible without CFD.

Handpicked content:

Energy saving technologies make a ship run more efficiently and CFD can help you find the right energy saving technologies for your ship. What’s the best way to save energy and keep your ship competitive? This white paper tells you all you need to know: CII rating: 11 smart ways to boost it while staying competitive.

Fact 2: CFD shows how components work together

In its earliest days, CFD was used to improve the performance of individual components. Now it considers the vessel as a whole and how it behaves in the water. Understanding how components work together leads to even greater performance improvements, allowing greater optimisation than would be possible individually.

For example, CFD can dramatically improve the way azimuth thrusters interact with the ship’s hull. Experts using CFD found that tilting the angle of the propeller shaft by 8° significantly reduces interaction with the ship. This is a game changer if you look at overall ship efficiency – a small change, made possible by CFD, that delivers up to 20% higher effective thrust.

These CFD-inspired changes help to minimise fuel consumption and contribute to the decarbonisation of shipping.

Fact 3: CFD can help to fix design flaws even after a ship is in the water

If an issue with your ship’s design comes to light during the sea trial, you need to act fast. CFD can help to iron out design problems even at this late stage in the process. Wärtsilä’s CFD experts have often stepped in to find solutions to issues even when it hasn’t been the company’s responsibility.

In one case a propeller showed unexpected vibration levels. A detailed CFD simulation of the vessel showed it was the inflow causing the problems, due to poorly aligned brackets. Without CFD it could have been assumed that it was the propeller itself causing the issue, rather than something that could be fixed with a small modification.

In another case the shipyard didn’t use the right waterjet inlet duct design. Some quick simulations showed them how, with minimal welding and grinding, they could fix the problem. It was a subtle difference – but enough to get the performance over the design threshold and the vessel ready to be handed over to the customer.

In this case CFD was then used to design a new waterjet inlet duct for the sister vessel, which resulted in a top-performing ship that could accelerate from 0–55 knots (approx. 100 km/h) within 60 seconds.

Fact 4: Your smartphone has more computing power than the first CFD workstations

The first workstations Norbert was using in 1997 for CFD had 300 MB RAM and a 4 GB hard drive. Nowadays the smartphones in our pockets are vastly more powerful than those first CFD machines.

Modern computing power means CFD experts can now run simulations that are 100–300 times more complex than they were when CFD was in its infancy. Designers can run multiple simulation projects simultaneously and with a level of accuracy that the first CFD users would have found mind-blowing.

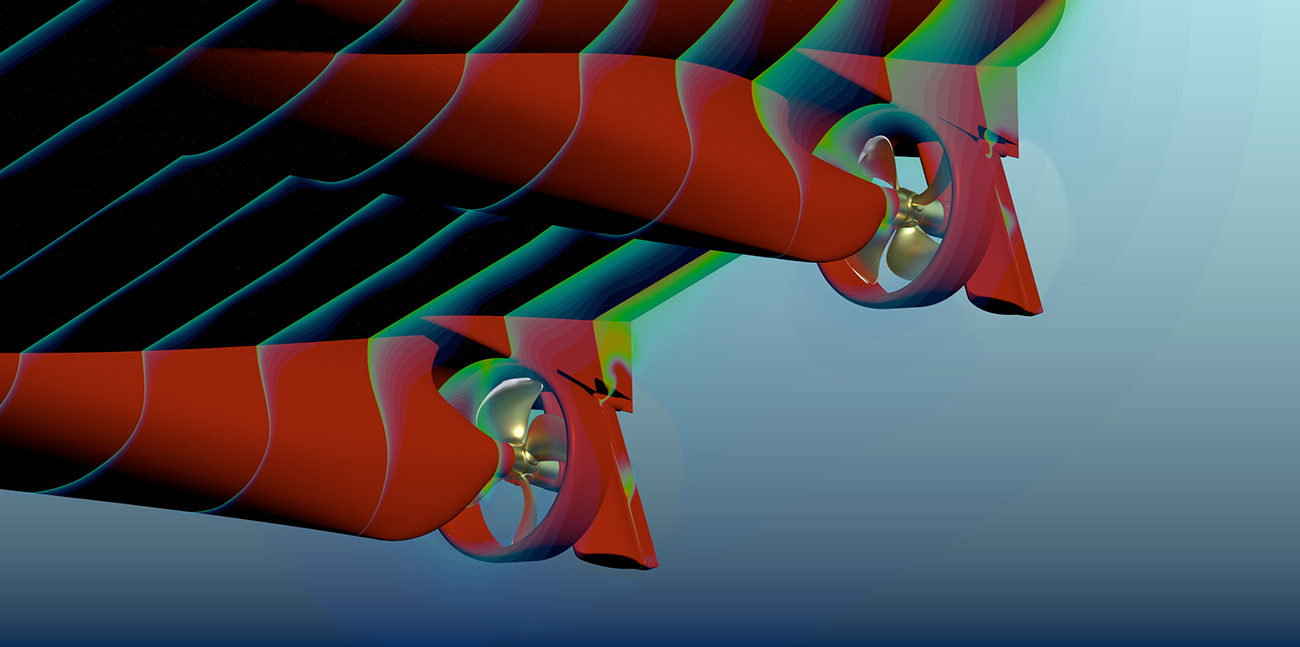

In CFD, simulated models are divided into cells which show the pressure and water velocity in three directions. Put simply, the more cells you have, the more accurate a simulation is. In the past it would have been common for a model to have around 200,000 cells. Today, thanks to modern computing power, CFD experts are working with models that have 20 or even 50 million cells.

“In 1997 I was using a single workstation, but now we have a cluster of about 1,600 computers.

Fact 5: CFD is making the impossible possible

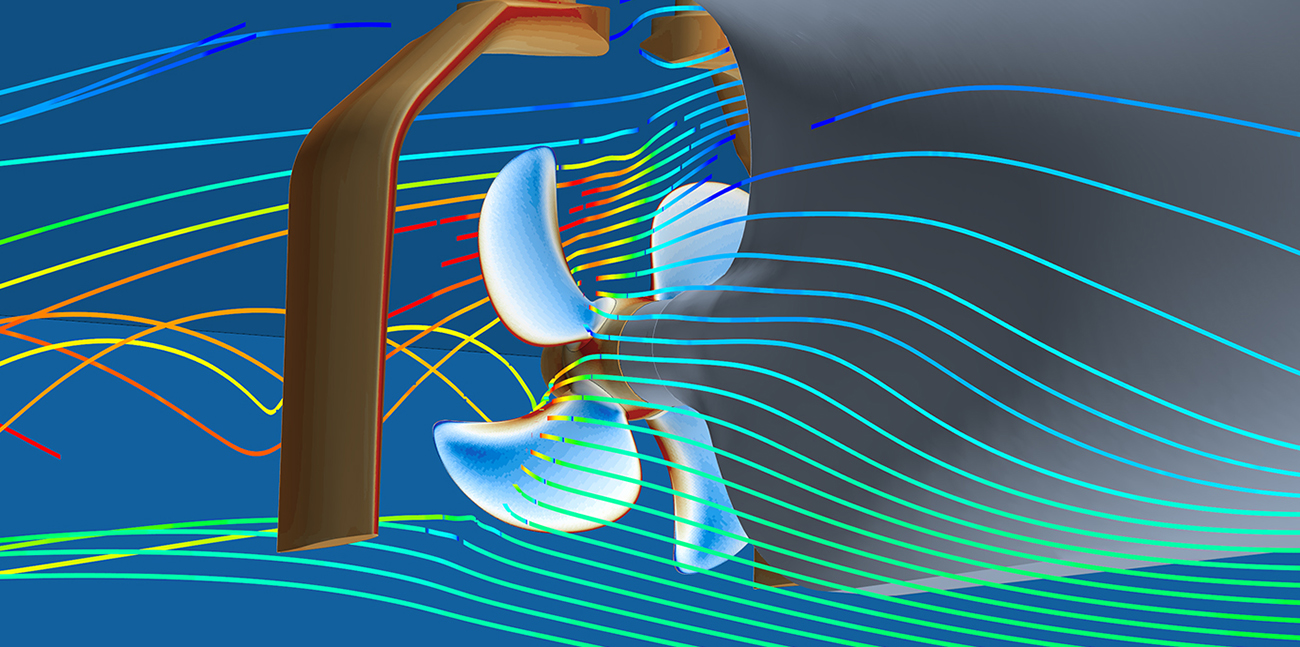

For those who are used to relying on model-scale testing, it can be a leap of trust to believe in CFD analysis. That makes Wärtsilä’s decades-long successful track record very important – but seeing is believing. The best way to help people understand and visualise the results of CFD calculations is with virtual reality (VR).

Virtual dive inspections using VR glasses show things which would otherwise be impossible to demonstrate – letting anyone who wants to see where the water is flowing for themselves. In real life a diver couldn’t go anywhere near a moving vessel, but in VR you can switch the propellers on and swim through them.

This gives you first-hand experience of how the water is flowing and affecting your vessel in a way that is clear and easy to understand. Dive into this animation to see for yourself:

Want to find more ways in which CFD is making the impossible possible? A picture is worth 1000 words in this Insights article: Optimising propulsion the smart way: 13 amazing pictures.

Fact 6: CFD will eventually make physical testing a thing of the past

Model-scale measurements have been the industry standard for over 100 years. But CFD is changing the game again. As computing power has increased and CFD has advanced, it is now often doing a better job than model-scale measurements. Crucially, it is also faster and cheaper.

For customers that want to test in a model basin, CFD can provide the performance curves for model-scale and the model tests will confirm it.

CFD can also produce full-scale simulations. Why is this important? Well, the more we learn, the more we discover where the assumptions of model-scale have got it wrong.

For example, in the case of a vessel with a duct it’s crystal clear that model basins don’t accurately represent what’s happening. A full-scale CFD simulation is the only way to get the accurate data you need.

Conclusion

CFD has certainly changed the game when it comes to designing, optimising and troubleshooting vessels. By showing how different ship components work together underwater, CFD makes it possible to:

- Improve a vessel design in a matter of hours

- See how different components will work together in practice

- Help fix design flaws even after the ship is in the water

- Run simulations with mind-blowing accuracy

- Clearly visualise a vessel in action

- Move past the limitations (and costs!) of physical testing

If you are a vessel owner or operator, CFD can help you to make significant savings in vessel energy efficiency. Looking for more ways to save energy? Download the white paper, CII rating: 11 smart ways to boost it while staying competitive.

This article about CFD and vessel design and optimisation first appeared as one of Wärtsilä’s Insights stories.