OPTI Design for better vessel efficiency

To achieve a perfect match between the propeller, engine and hull, the design has to be absolutely right. The Wärtsilä OPTI Design is the result of highly experienced design engineers having access to the very latest and most sophisticated software and analysis tools. Wärtsilä’s OPTI Design methodology is used to improve product performance in a way that was not earlier possible with conventional design methods.

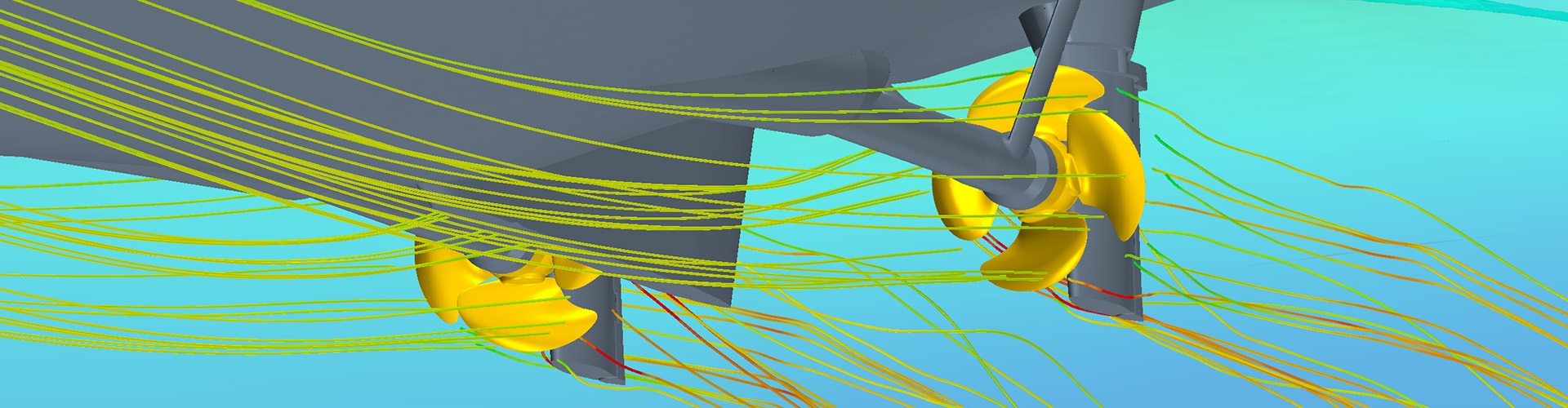

CFD calculations analyse not only the propeller performance, but most importantly also, the interaction between the propeller and hull. By utilising these numerical calculations of the flow to determine the effects of interaction between the propulsion unit and the vessel itself, the OPTI Design process delivers optimal efficiency. This in turn leads to reduced fuel consumption, fewer exhaust emissions, and lower operating costs. It is a customer-oriented process that involves close cooperation with the ship designer and vessel owner.

The OPTI Design technology enables Wärtsilä to deliver products that create the maximum possible benefit for the ship owner. At the same time, it reduces the risk of defects and costs related to imperfections, while shortening the entire design process. OPTI Design is an integral element of Wärtsilä’s integrated design philosophy.

Key benefits

- Reduced fuel consumption and improved EEDI

- Short turn-around cycles allow for additional low cost design iterations on the hull shape and main propulsion parameters (diameter, RPM of blades)

- Cost attractive evaluation of retrofits and energy saving devices

- Early propulsion and drive-line design choices can be checked

- Full scale CFD can be used for trim optimisation studies, which provide a good initial set of data for fine-tuning with the Eniram system

Methodology

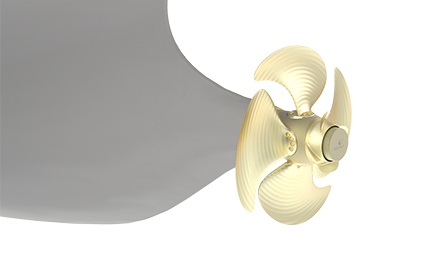

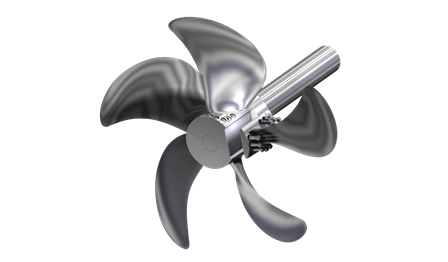

The OPTI Design methodology is based on years of proven experience, during which time more than 10,000 FPP’s and 20,000 CPP’s have been produced. They are designed using the most advanced technology and state-of-the-art equipment to ensure the highest possible levels of performance and efficiency. As a result, owners and operators gain the benefits of lower operating costs and a reduced environmental footprint through less fuel consumption and fewer exhaust emissions.

With OPTI Design the focus is on the vessel’s total propulsive efficiency, which in the end determines its fuel consumption. This propulsive efficiency depends in turn on the efficiency of the propeller and the interaction between the propeller and the vessel. This interaction is defined in the propulsion theory represented by the hull efficiency and the relative rotative efficiency.

In the past, the flow along the ship’s aft and the propeller were separately optimised. While the propeller flow along the vessel hull, as represented by a wake field, has always been taken into account, the interaction between ship and propeller, however, was assumed not to change for different propeller designs. With modern Computational Fluid Dynamics (CFD) tools it is now possible to calculate the ship and the propeller together, and thus find the best combination.

The CFD calculations can be made for both model scale and full scale conditions. Where until now the performance was always judged using a model scale test, the CFD makes it possible to analyse the performance at full scale, which is what really matters for the ship owner.

Press releases

Articles

Customer stories

Discover the benefits others have already gained from energy saving technologies.