SOx Scrubber systems

If the vessel operates in areas where SOx emissions are controlled, compliance can be achieved using low sulphur fuel, or by cleaning exhaust gases using SOx scrubbers. Wärtsilä has developed an open loop, a closed loop and hybrid scrubber systems. The basic technology in all these systems is the same. When exhaust gas enters system, it is sprayed with water. The SOx reacts with water to form sulphuric acid. In and open loop system, the natural alkalinity of the seawater neutralizes the acid. In closed loop system, caustic soda helps to do this. The hybrid approach enables operation in closed loop mode when required, for instance whilst in port and during maneuvering using caustic soda. When at sea the switch can be made to open loop using only seawater.

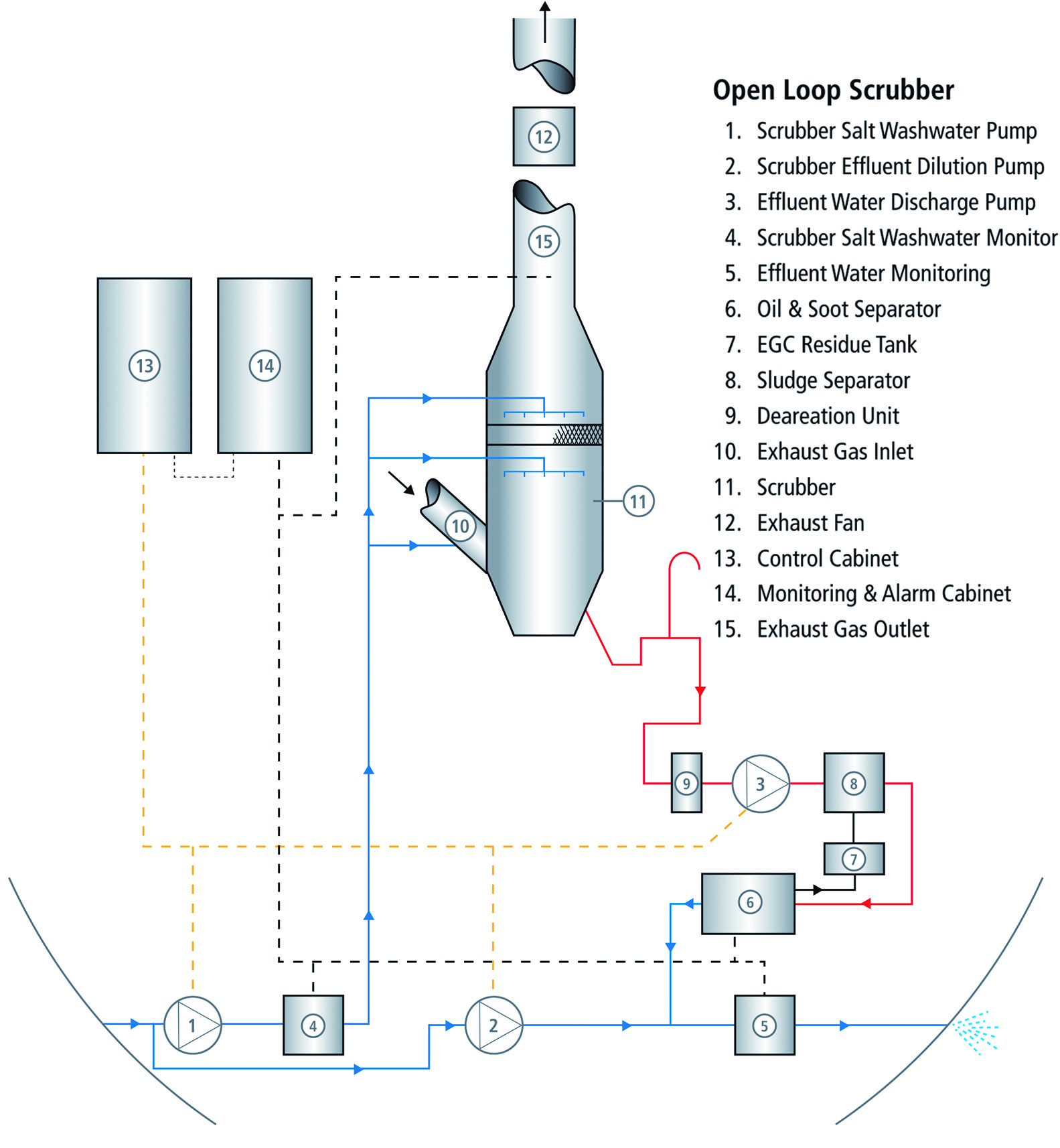

- Wärtsilä Open Loop Scrubber System

Wärtsilä Open Loop Scrubber system benefits from Hamworthy’s 50-year know-how. The system operates in an open loop, utilising seawater to remove SOx from the exhaust. Exhaust gas enters the scrubber and is sprayed with water in three different stages. The sulphur oxide in the exhaust reacts with water and forms sulphuric acid. There is no need for chemicals since the natural alkalinity of seawater neutralizes the acid. Wash water from the scrubber is treated and monitored at the inlet and outlet, to make sure it is in line with the discharge criteria of MEPC 184(59), before it is discharged to sea with no harm to the environment. LINEA MESSINA has an open loop scrubber system installed, and was the first vessel ever to operate commercially with a scrubber system, enabling it to meet 0.1% sulphur emissions regulations in EU ports, as well as “future proofing” the vessel for the impending 0.1% Emission Control Area limit in 2015.

- Wärtsilä Closed Loop Scrubber System

Wärtsilä Closed Loop Scrubber operates in a closed loop, i.e. the wash water is being circulated within the scrubber. Only a small bleed-off is extracted from the loop and fresh water and alkali is added. The SOx reduction efficiency is 97,15%, corresponding to a reduction of fuel sulphur content from 3.5% to 0.1%.

Scrubbing water is pumped from the wet sump through the cooler to the top part of the scrubber. Scrubbing water is sprayed into the exhaust gas flow from the spray nozzles in the scrubber. Water is also supplied to the mid part of the scrubber to further improve the SOx removal efficiency.

Scrubbing water passes through the packing bed and is collected and removed through the bottom. The water absorbs SOx emissions, heat and other components from the exhaust gas stream. The pH of the scrubbing water and thus the cleaning efficiency, is automatically monitored and controlled by alkali dosing.

The fresh water consumption is case dependent, but as estimation, 0.2 m3/MWh can be used. Fresh water topping-up is needed to compensate scrubbing water evaporation losses and extracted bleed-off. The topping-up water supply is connected to the scrubbing water wet sump or pump module. Fresh water is also supplied to the droplet separator on top of the scrubber for periodical rinsing.

The caustic soda is automatically added to the scrubbing water circulation to maintain the process pH and consequently the SOx removal effi ciency. The main components of the alkali feed system are the alkali pump, alkali feed control and alkali storage tank. The caustic soda consumption in weight is roughly 6 -15% of the diesel engine fuel oil consumption depending on the sulphur content and cleaning efficiency.

To remove the accumulated impurities from the scrubbing water a small flow of bleed-off is extracted and led to the emulsion breaking water treatment unit. The bleed-off contains traces of oil and combustion products, and its pH is typically close to neutral. Clean effluent from the treatment unit is discharged overboard, or led to the effluent holding tank when overboard discharges are to be avoided. Effluent quality monitoring is arranged before the discharge.

The extracted bleed-off from the scrubbing water circulation can be led to a bleed-off buffer tank prior to the treatment unit. A bleed-off buffer tank can be arranged to offer operational flexibility, permitting operation of the scrubber with the treatment unit out of operation.

Read more about exhaust gas treatment solutions