PIPELAYING METHODS

S-lay method

Conventional method for rigid pipe. When using the S-lay installation method, onboard welded pipe joints leave the vessel horizontally and are guided to the seabed over a “stinger” - a structure on the back of the ship that supports the seagoing pipe string to control its bend radius. The pipe is lowered using tensioners. Due to its high production rate and the possibility to install concrete coated pipe, S-lay is extremely suitable for pipe installation in shallow and intermediate waters. Larger water depths are equally possible but require a very long stinger, turning S-lay into a less practical and efficient solution.

- J-lay method

One method for installing subsea pipelines in deepwater is by J-lay installation. Pipe stalks with a length up to 6 joints are upended and welded to the seagoing pipe in a near vertical ramp. The ramp angle is chosen in such a way that it is in line with the pipe catenary to the seabed. The J-lay method is very suitable for deepwater as the pipe leaves the lay system in an almost vertical position. The pipeline is only bent once during installation (at the seabed) which is advantageous for installing pipelines that are sensitive to fatigue. Compared to other lay methods, J-lay has a relatively low production rate due to the single welding station. The J-lay method is less suitable for shallow waters as this requires a steep departure angle.

- Reel-lay method

Reel-lay and carousel-lay are used for rigid and flexible pipes: large lengths of pipe are welded, tested and coated onshore and then spooled on vertical reels or horizontal carousels on board the lay vessel. During pipelay the pipe is unspoooled from the reel or carousel. Straightening of the pipe is required before it is over boarded. The advantages gained by the high production rate as well as the controlled welding and inspection conditions onshore, make Reel-lay an extremely efficient method for the installation of pipelines up to 20 inch in all waters.

See also Flexible pipelaying ship SEVEN SEAS

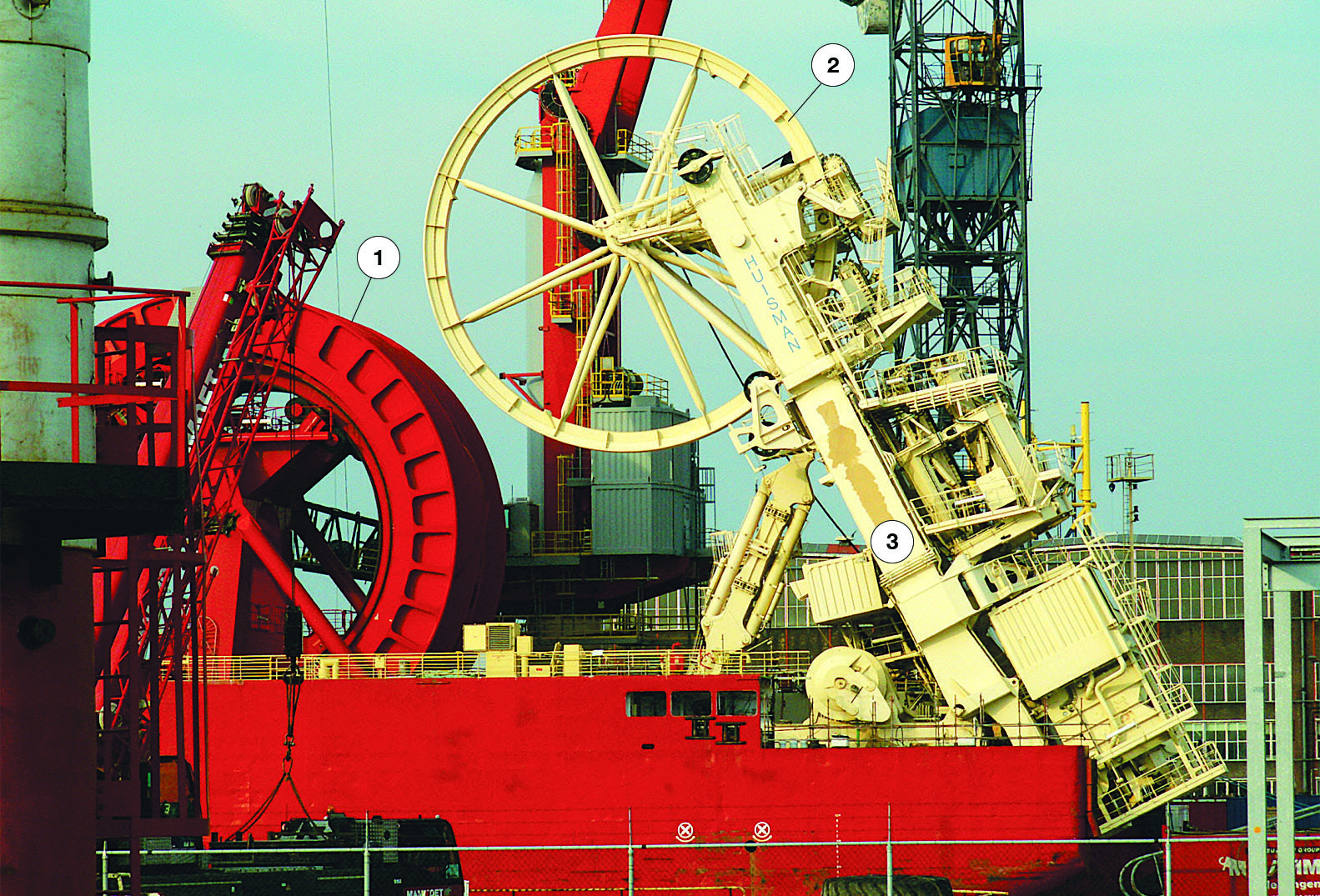

- Combination of Reel-lay and J-lay

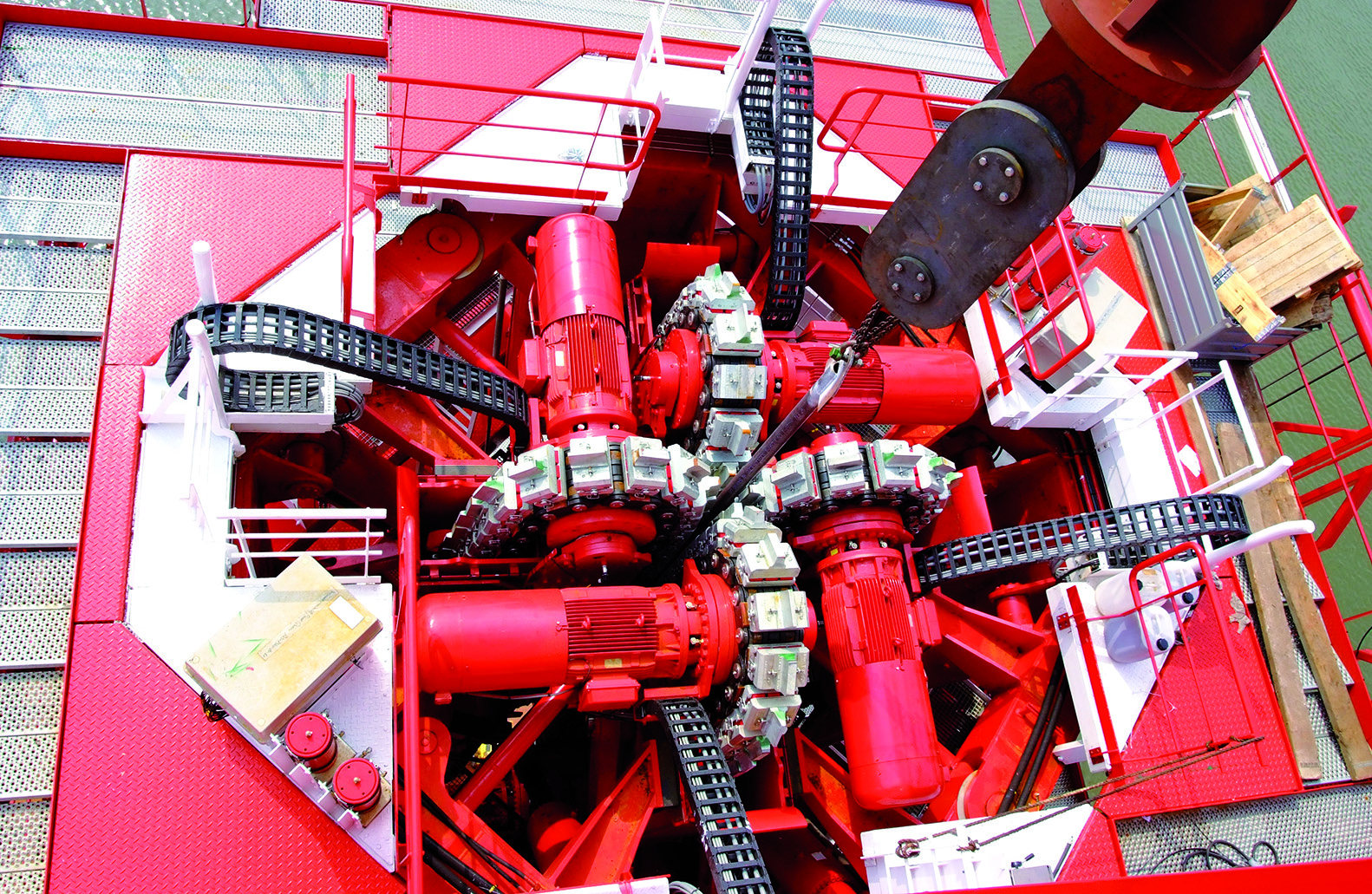

Using the reel lay method, pipe is welded onshore into long lengths, which are coated and loaded onto a large storage reel on the vessel. The pipe is plastically deformed around the hub of the reel.

When the pipe is laid offshore, it is pulled off the reel over an aligner at the top of the lay ramp, passed through a straightening system, and the process of lowering the pipe to the seabed is controlled by linear tensioners which grip hold of the pipe as it passes. The main benefit of this approach is that much of the welding and coating is undertaken onshore.

See also Rigid pipelaying ship SEVEN OCEANS

Typical components for pipelaying systems are:

- Pipe tensioners

- Abandon & Recovery winches

- Hang of clamps

- Pipe straighteners

- Line up systems,

- Pipe storage reels

- Carousels

- Pipehandling equipment

- Pipe transfer cranes

- Stinger handling systems.

For further information visit www.huisman-itrec.com