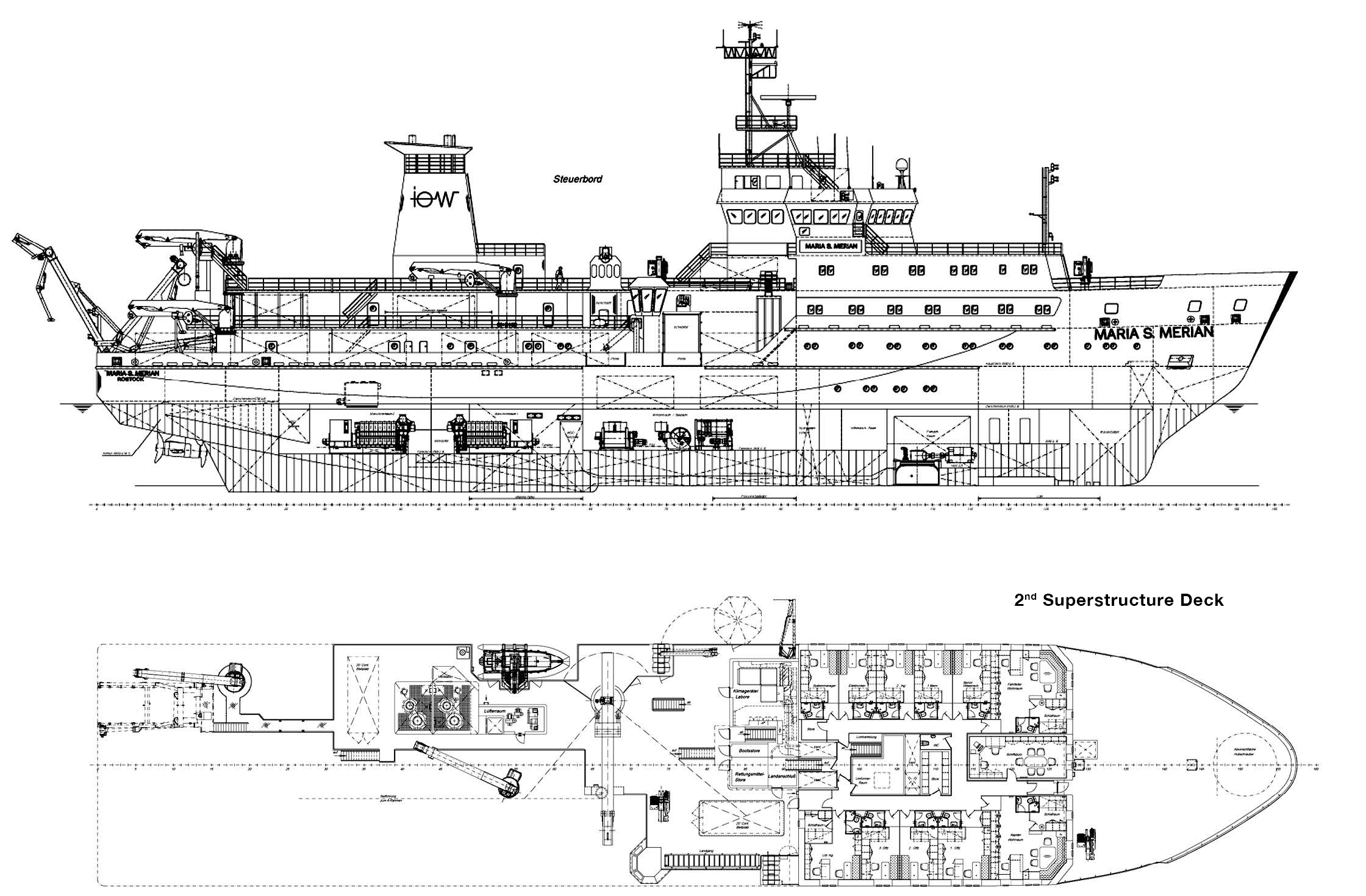

Climate research vessel MARIA S. MERIAN with podded propulsion drives

One of the world’s most advanced oceanic research ships was christened the “MARIA S. MERIAN” on 26 July 2005, honoring the German woman who is recognized as the world’s first entomologist. The ship is poised to play a prominent role in oceanic research and allow scientists to document the physical realities of climate change while investigating the current health of the world’s oceans. Its geographic scope will reach from the Arctic Circle to the northernmost reaches of the Gulf Stream. Equipment aboard the ship can create images of the ocean floor up to 10,000 meters deep.

Although the order was placed with Kroeger Werft, the building of the ship was contracted out to Polish shipyards: Maritim Ltd in Gdańsk and Naval Shipyard in Gdynia.

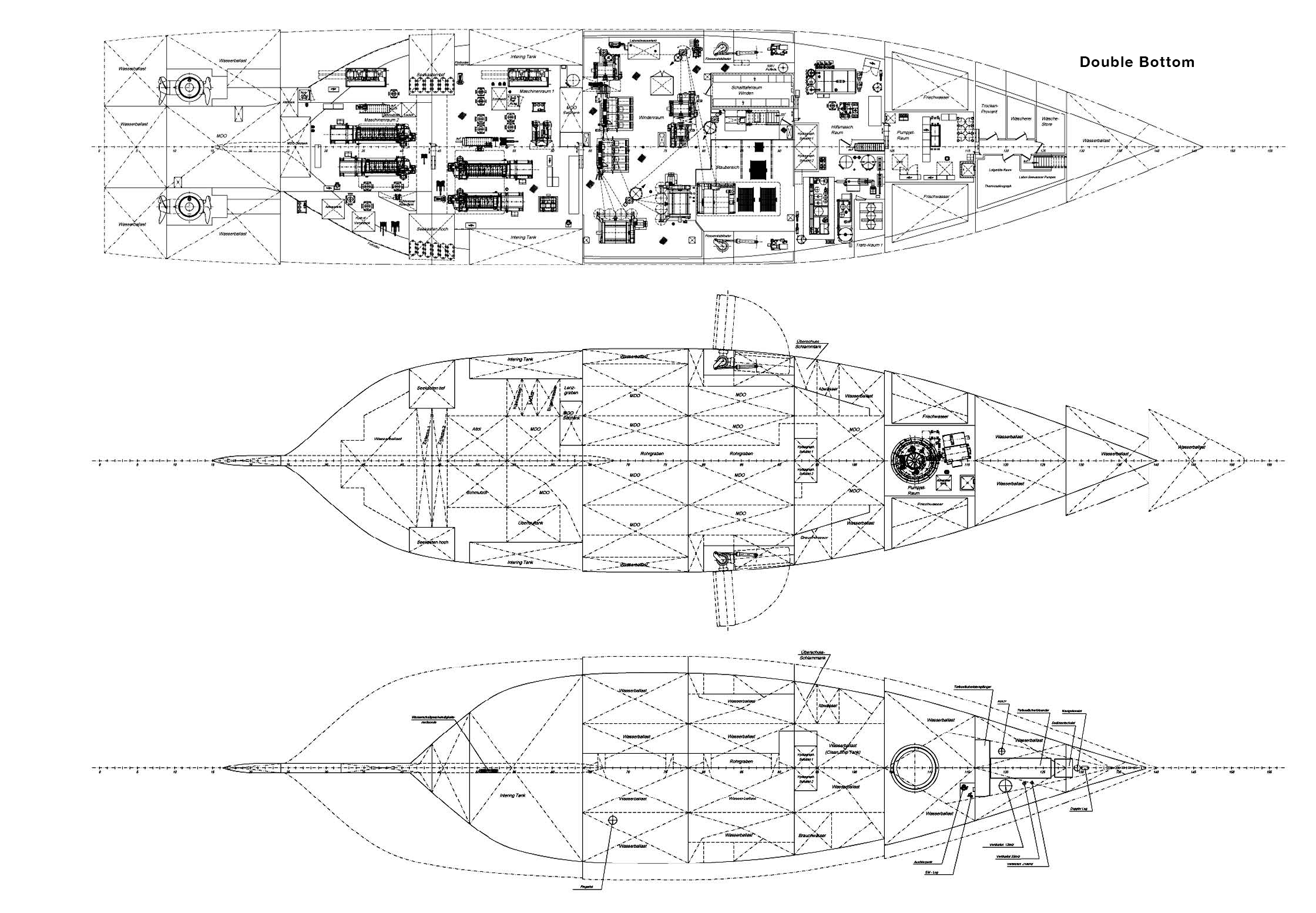

The ship is powered by a diesel-electric propulsion system comprising two 1600kW 8L21/31 and two 1200kW 6L21/31 diesel gensets, two 2050kW Schottel Electric Propulsors as well as a 1600kW Schottel Pump Jet type SPJ320 as a manoeuvring aid.

The L21/31 engines are the first in the world to have been delivered in compliance with the ‘Blue Angel’ emission standard. The engines were specially adapted to low NOxemission levels (without any fuel penalty) by optimising the primary process internally in the engine and without any after-treatment of the exhaust gas.

The pods drive the vessel at a maximum speed of 18 knots and a service/cruising speed of 15 knots.

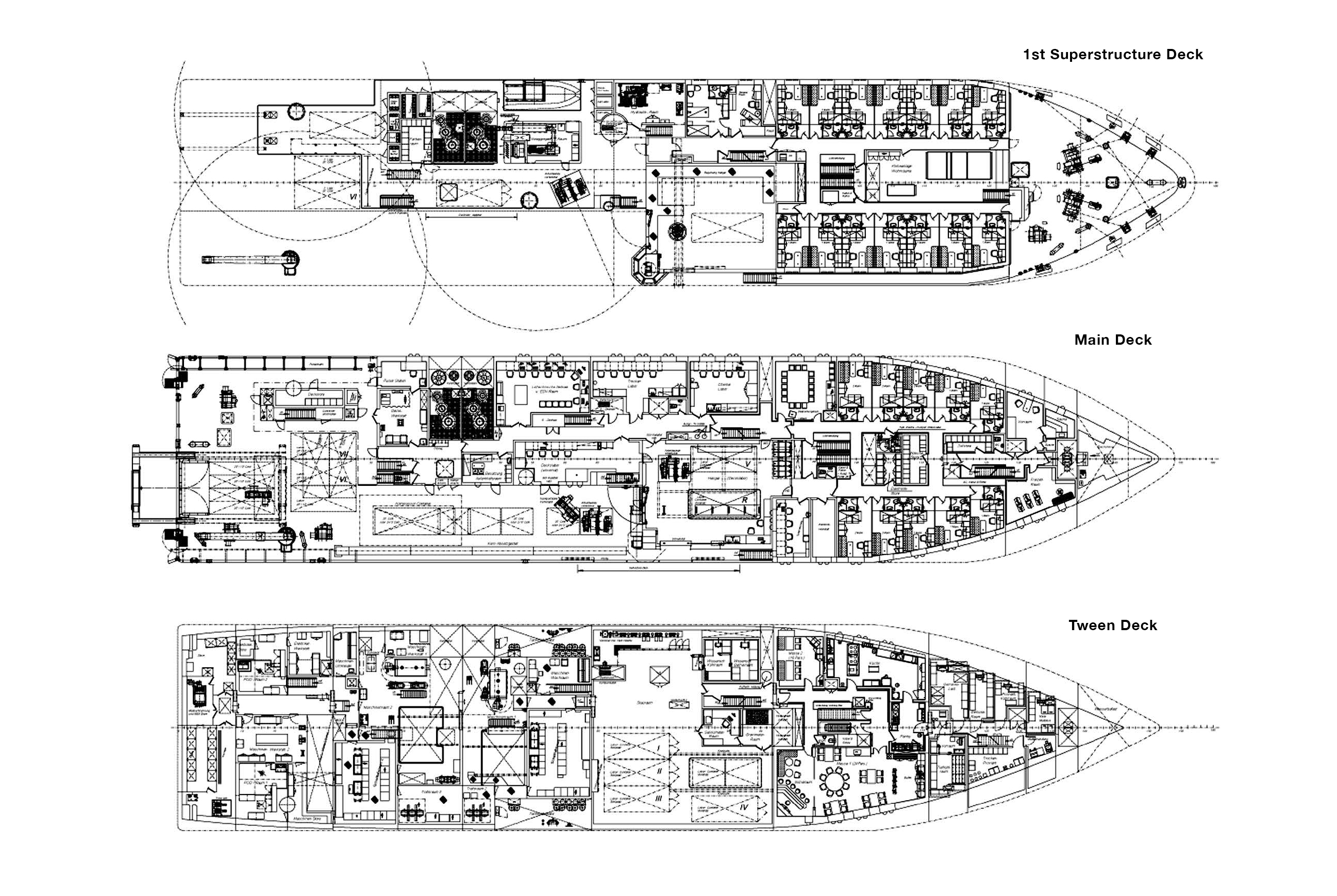

A number of novel features are incorporated, among these are seven special winches supplied by Hatlapa. One speciality is the combination of friction and storage winch for handling the very long and relatively thin measuring cables. The advantage is that the sensitive and expensive research ropes can be spooled on the storage winch free from load. The pull is created in the friction part and exerted via several grooved drums to protect the rope. A spooling device also guarantees the rope to be wound onto the storage winch in a clean and gentle manner. Thereby the crossing of rope layers resulting in rope breakages are avoided. The storage winches have a very large drum diameter for realising low bending radia of rope for protecting the sensitive measuring wires in the ropes.

The ropes are not just normal synthetic or steel wire rope, but consist of a single cable with an outer coating of synthetic material to protect the conductor against damage, to guarantee the necessary shielding, and to absorb the forces.

Constant communication between the control and measuring instruments is possible by transmission rings in the winch, also during paying-out and hauling-in the rope. Furthermore, lighting conductor cables are in use which have a similar structure, allowing also constant communication between the control and measuring instruments.

By using frequency inverter controlled motors, the speed can be infinitely controlled and the winches operated synchronously. The otherwise usual maximum demands on the shipboard power supply, the ropes and mechanics are eliminated, because the winches are on stand-by from zero speed to full torque, thus allowing a smooth start. The electric driving capacity of each winch is up to 352kW, which is produced by 4 motors of each 88kW. By using 4 motors, capacity reserves are increased on the one hand, and on the other hand, the distribution of the load into the gear allows a compact construction. To dissipate the heat arising in the electric motors, water-cooling has been provided.

Length (oa): 94.8m, Breadth: 19.2m, Draught (max): 6.5m, Speed: 15 kn, Class: GL + 100 A5 E3 Nav-OC (special vessel) + MC E3 AUT RP3 50% strengthened to Polar Class PC 7