In the highly competitive electricity generation market, flexibility and efficiency are two of the key competitive advantages for power companies. As these companies seek to set themselves apart from the competition, Wärtsilä has responded by launching the most efficient multi-fuel engine for flexible and reliable power generation - Wärtsilä 31DF.

When power generation is distributed across a variety of different energy sources, the stability and resilience of the energy system increases. Distributed flexible power generation and the use of a multi-fuel solution to increase system-level resilience, creates energy security in the event of issues caused by natural disasters or problems in the fuel logistics chain, politics or prices.

“A power plant that runs on multi-fuel engines is quicker to start up and has the flexibility to run on multiple fuel types, thereby securing access to energy regardless of what happens in the world,” says Jani Mäkinen, Product Manager, W3X Gensets. “Importantly, operators using Wärtsilä’s highly efficient engines also stand to benefit from reduced fuel costs and improved environmental performance.”

Already used in a number of applications in the shipping industry, Wärtsilä has now launched to the energy market the Wärtsilä 31DF, a multi-fuel engine version of the Wärtsilä 31 engine family in its 20-cylinder version providing a 11 MW output per unit. It is ideally suited for customers looking to gradually transition to gas-powered operations, especially in geographic locations where pipeline gas or LNG deliveries are not yet available or sufficiently secure to justify an out-and-out switch, meaning that provision for liquid fuel operation is omitted and the plant is fully optimised for gas-only operation.

“In this day and age, fuel security is a top priority and, in many places, the cost and availability of gas can still vary quite a bit,” continues Mäkinen, explaining that the Wärtsilä 31DF engine has been specially developed for customers who want to start operating on gaseous fuels or who intend to do so in the near future, but are not yet ready to commit to it exclusively.

“When using flexible multi-fuel engines, you can rest assured you will never be forced to switch off the lights, even if something unforeseen were to occur in the fuel supply chain – Wärtsilä 31DF is capable of instantly switching fuels to a back-up liquid fuel without any disturbance in the electrical output,” he adds.

Huge potential for island nations and isolated power systems

The flexibility offered by multi-fuel engines makes the Wärtsilä 31DF engine ideal for use in isolated power systems that typically refer to power plants that operate independently of the countrywide electricity network, such as islands in remote locations and major off-grid power consumers like mines.

“We foresee huge potential for the Wärtsilä 31DF in island nations such as Indonesia, the Philippines and the Caribbean islands, where power systems are typically isolated and separate from large national grids,” says Mäkinen.

The Wärtsilä 31DF engine has a wide load range with high part-load efficiency. Its two-stage turbocharging enables more energy to be recovered from the exhaust gases resulting in significantly enhanced engine efficiency.

In addition, customers who choose the Wärtsilä 31DF engine also stand to benefit from outstanding operational flexibility, as it takes only two minutes to go from start command to full load. It is also able to switch over from liquid fuel to gas and vice versa seamlessly during engine operation.

Third member of the Wärtsilä 31 engine genset family

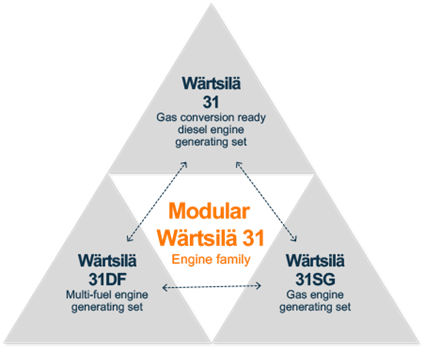

The latest addition is the third piece of the Wärtsilä 31 engine generating set puzzle, which comprises the original Wärtsilä 31, a gas-conversion-ready diesel engine generating set, and the Wärtsilä 31SG, a spark ignited pure gas engine generating set, launched to the energy market in 2017.

One of the most state-of-the-art features of the Wärtsilä 31 engine family is its modular design, which makes it 100 percent future proof. Each of the three engine types can easily be converted to support one fuel type or another, making customers ready to adapt to all possible eventualities, regardless of the type of fuel that is available to the customer now or in the future.

Mäkinen explains: “Say a customer buys a Wärtsilä 31 today because they operate in a region where gas is not available, but they still want to start producing electricity using only liquid fuel. Two years from now, they may have access to some gas but, due to uncertainties in supply and price, they cannot rely on it fully, so they may decide to convert the engine to a Wärtsilä 31DF. A couple more years down the line, when they are ready to operate fully on LNG, they can convert the engine to an LNG-powered Wärtsilä 31SG.”

What’s more, there is no difference in performance between a product that has been converted and one that was built for purpose from the outset.

“There is no compromise whatsoever if you invest in one product with a view to converting it,” continues Mäkinen. “The beauty of the modular design is that it’s easy to remove a module and replace it with another with no compromise on power output or efficiency. This is why modularity has been such a central feature of this product family since day one.”

Wärtsilä’s modular power plant design also helps minimise downtime and lost output. Units can be converted one after another while the plant continues operating at full capacity throughout the conversion time.

The Wärtsilä 31 Engine Family.

Dual-fuel power plant market leader with total offering

Over the years, Wärtsilä has established itself as a global frontrunner in dual-fuel power plant technology. Its capacity is unrivalled, offering everything from engine deliveries and installation to full Engineering, Procurement and Construction (EPC) setup and lifecycle services. In the last three decades, the company has delivered equipment and knowhow to 205 dual-fuel power plants across 47 different countries around the world.

Customers also stand to benefit from Wärtsilä’s complete lifecycle approach for optimising the efficiency and performance of a power plant. All of Wärtsilä’s Lifecycle solutions can be customised to suit the power plant’s operating profile and respond to the needs of the power plant owner and operator in the most efficient way possible. The solutions provide guaranteed operational reliability and efficiency, and performance guarantees are agreed upon on measured data.

The result of many years of R&D work

Developed from scratch in house, the Wärtsilä 31 engine generating set family is the accumulation of all the experience and expertise Wärtsilä has built up over the years. It contains state-of-the-art features developed over the course of more than a decade of dedicated research and development work.

“Throughout the development of this ground-breaking product, we remained firmly focused on the future and the expectations our customers will have in the years to come,” he says. “Perhaps most importantly, efficiency was never compromised on.”

From the outset, Wärtsilä’s intention was always to develop a family of products that would offer unparalleled efficiency and that could gradually be optimised for a multitude of fuel capabilities.

Future-proof product

“From now on, Wärtsilä will continue to develop the Wärtsilä 31 range into the future. In the years to come, we will further enhance its efficiency, output and dynamic performance as well as its fuel capabilities,” says Mäkinen.

“Looking further into the future, there is every reason to believe that we will adapt this engine family for an even wider range of fuel options, including synthetic fuels and a variety of renewable power generation alternatives. This is why we call it a truly future-proof product,” he concludes.

The Wärtsilä 31DF engine was launched at POWERGEN Asia in September 2019 and deliveries are set to begin in 2020.

Read the press release for more details: New Wärtsilä 31DF engine makes entry to energy industry with unprecedented efficiency with fuel and operational flexibility.