Wärtsilä Retrofit pulse lubricating system

A retrofit solution for reducing cylinder oil consumption without compromising piston running reliability

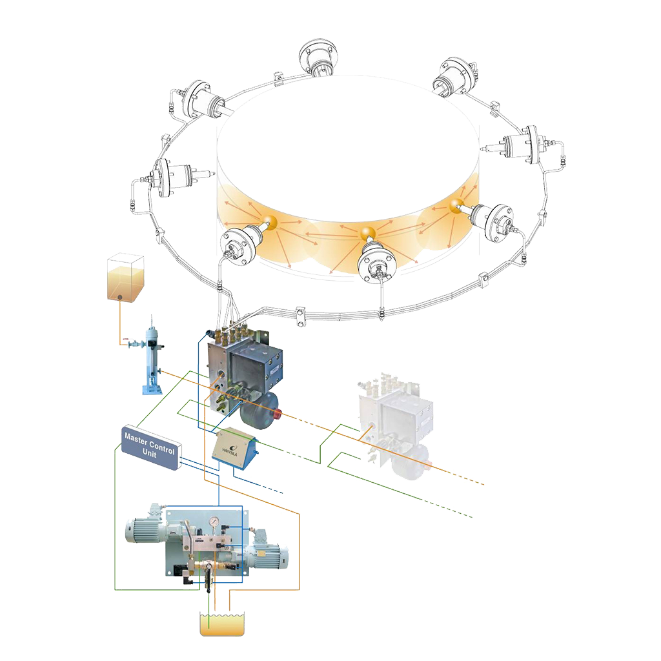

The costs for cylinder lubricating oil have become a critical issue for vessel operators, with market prices for lubricating oil constantly fluctuating while availability can be limited. To help alleviate this situation, Wärtsilä has developed an electronically-controlled retrofit lubricating system, the Retrofit Pulse Lubricating System (RPLS), to serve the demand for lower cylinder oil feed rates. It delivers reduced cylinder oil consumption without compromising piston running reliability.

The reduction in the cylinder oil feed rate provided by the Pulse Lubricating System, compared with existing accumulator systems, is made possible by improving the distribution of the cylinder lubricating oil to the piston ring package, and by the precise timing of the oil delivery.

Key benefits

- Reduced cylinder lubricating oil consumption leading to a reduction in total operating costs

- Precise injection of cylinder lubricating oil into the piston ring package

- Accurate metering of cylinder lubricating oil to achieve potential savings

- Less build up of deposits thanks to reduced lubrication

- Reduction in solid particle emissions due to reduced lube oil consumption

Technical info

The basic principle of the Pulse Lubricating System is to deliver metered quantities of cylinder lubricating oil, at precise timing under pressure directly into the piston ring package from where it is evenly distributed around the circumference of the cylinder liner.

The guide feed rate for Wärtsilä RTA and RT-flex engines retrofitted with the Pulse Lubrication System is 0.8 g/kWh of cylinder lubricating oil. With a traditional specific oil consumption of 1.1 – 1.6 g/KWh this means that the consumption can be reduced by 30-50% following retrofitting of the engine with RPLS.

Application

RT-FLEX84T-D, RT-FLEX96C, RT-FLEX96C-B, RTA58T, RTA58T-B, RTA58T-D, RTA62, RTA62U, RTA62U-B, RTA68, RTA68-B, RTA68-D, RTA72, RTA72U, RTA72U-B, RTA84C, RTA84C-U, RTA84M, RTA84T, RTA84T-B, RTA84T-D, RTA96C, RTA96C-B