Do you want to reduce emissions and increase cargo capacity of your LNG carrier?

The pressing need to decarbonise shipping is leading to an unprecedented era of new innovations in sustainable fuels, electrification, energy saving devices and operational optimisations. This requires more flexibility from the propulsion system.

New ship electrification technologies will bring other significant benefits on top of reduced emissions, especially for LNG carriers. Increased cargo capacity is one of them, and there are others that will prepare your vessel for the future.

Get

6% more cargo space: meet the next-generation hybrid-electric LNG carrier

design

A new hybrid electric design for LNG carriers has five compact generating sets instead of the typical two large, 2-stroke engines and four auxiliary generating sets.

Because this design saves space, the cargo capacity of a standard 174,000 cbm vessel will increase by 9000 cbm below deck.

What’s more, the new design reduces equipment weight by over 40%. This means that even with more cargo, the overall vessel displacement, draft, and hull performance will be the same as current designs, enabling it to be compatible with standard large LNG terminals.

The increased cargo space will lead to

- higher trading revenues

- lower unit freight costs

- reduced emissions per ton mile.

185,000 cbm Hybrid Electric LNGC

Electric propulsion – proven in use

Electric propulsion has been in use in many shipping segments for several decades and is highly proven technology including in the large LNG carrier segment where there are approximately 230 vessels in operation today with electric propulsion.

There has recently been a clear increase in the uptake of hybrid electric propulsion as an alternative to mechanical propulsion in segments such as small merchant vessels and ferries as owners invest in more flexible and future proof solutions - underlining the increasingly large role electrification will play in maritime decarbonisation.

Higher efficiency - lower emissions

Although LNG carriers are designed for a speed of 19.5 kn, several sources indicate the current average sailing speed to be around 15 kn. This means that when applying the current 2-stroke solutions they are not operating optimally – and therefore, their emissions are higher.

Considering the actual operating profile of today's LNG carriers, the new, modular hybrid electric design will achieve the following, approximate savings:

Reduction in fuel consumption

Reduction in greenhouse gas emissions

Reduction in methane slip

Reduced maintenance costs and built-in redundancy

The energy storage – the vessel battery - in the new hybrid electric design will result in higher load factors and greatly reduced running hours. As a result, maintenance costs will be significantly lower.

Because the vessel battery takes care of dynamic loads, the generating sets can run at high and steady state loads. The operation will be more efficient and there will be less wear and tear on the engines.

Hybrid electric propulsion systems also provide exceptional redundancy thanks to their modular arrangement and built-in redundancy in the electric distribution system. This provides the benefit today of guaranteed uptime and provides a correct foundation for the future considering the longer-term ambition towards more automated and unmanned engine room and vessel operations.

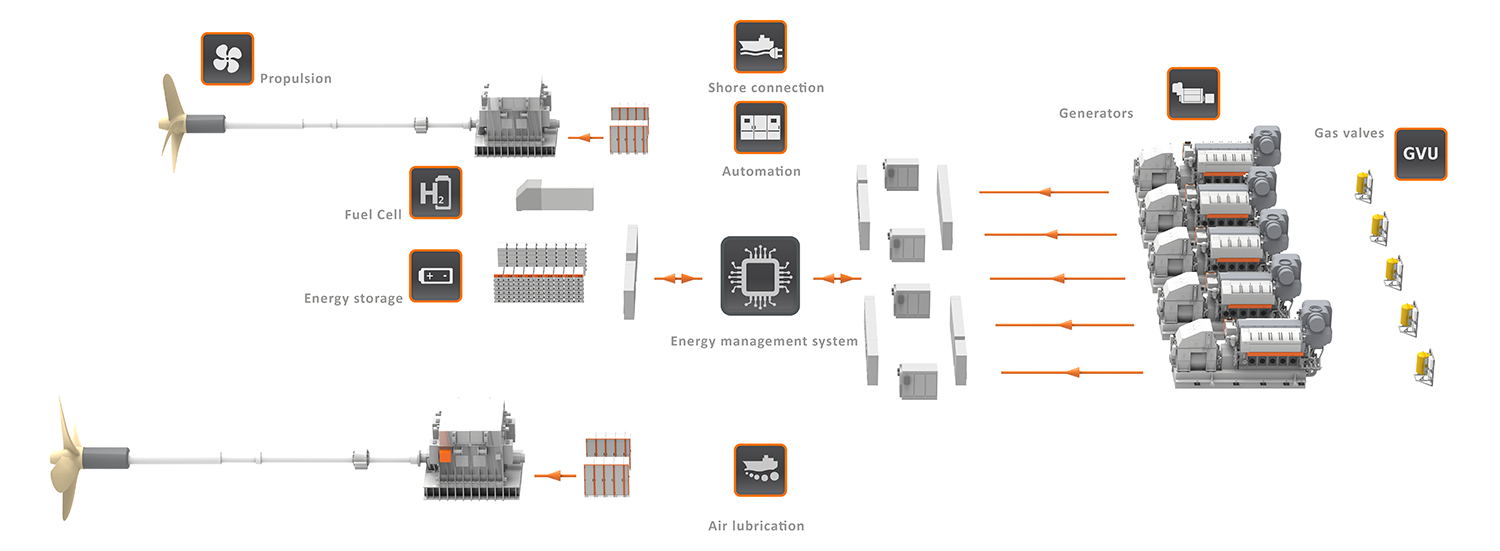

Hybrid Electric Propulsion System Overview

Fuel flexibility

The Wärtsilä 31 engine platform is highly modular and can easily be converted to use different fuels, including LNG, bio-LNG, synthetic LNG, HFO, MDO, and a variety of biofuels. The platform is also capable of running on blends of these fuels, including sustainable options, and is targeted to be capable of operating on carbon neutral and zero carbon fuels in the future. The introduction of future fuels can certainly impact engine power ratings, dynamic performance and even the availability of new energy converters capable to use future fuels. With this is mind, the flexibility benefits of electric propulsion should not be overlooked either as a key enabler to accelerate future fuel introduction.

Electrification and energy saving technologies

Full battery electric propulsion is not yet feasible for ocean-going cargo ships because the energy density of batteries is insufficient to meet the large energy demand of ocean-going ships. However, future developments in technology will lead to increasingly more installed battery capacity and range for marine vessels. In addition, a wide range of new electrical devices such as fuel cells, solar panels and heat to power are emerging that will require a modular and flexible propulsion system that is ready for zero emissions.

Energy saving technologies, ESTs are a great way to improve vessel efficiency. ESTs include wind-assisted propulsion, air lubrication, special propulsion solutions, and optimised hull lines. ESTs together with slow steaming will further reduce power demand from engines in the future and will benefit from a modular power system that maintains high efficiency in all power conditions.

The modular hybrid electric plant is best positioned to efficiently adapt to changes and introduce new technologies cost-effectively in a plug-and-play electrified system.

Decarbonisation drives down engine power demand

Secure your future

Decarbonisation of shipping requires new technologies and innovative, flexible propulsion solutions. Hybrid electric propulsion can be your secure investment for the future.

Wärtsilä’s expertise covers the full spectrum of propulsion solutions and services. Ensure your competitiveness - get in touch and let’s discuss your needs and options!