Have a strong ability to customize process systems to the customers needs

Wärtsilä’s liquefaction plants are easy to operate, reliable, and fully automated. They represent a low lifecycle cost solution in the small to medium size liquefaction capacity range.

Our liquefaction plants are based on the reversed Brayton nitrogen refrigeration cycle, with commercial grade nitrogen as the sole refrigeration medium. We can provide the basic complete process package, as well as civil engineering and construction services. The complete plant can also be supplied as an EPC delivery. Once installed, Wärtsilä further offers operation and maintenance agreements tailored to the customer's specific needs.

Technical data

Applications

Key benefits

Technical data

Our liquefaction process is based on proprietary reversed Brayton technology. Commercial-grade nitrogen is the sole refrigeration medium and is used in a process of compressing and expanding the nitrogen to obtain the required cryogenic temperature.

Gas sources can typically be pipeline gas, well gas, or flare gas. The gases need to be cleaned to achieve low contents of water (1 ppm), CO2 (<50 ppm), and H2S (< 4ppm). Gas cleaning systems can also be delivered by Wärtsilä upon request.

Main technical data:

- Energy consumption: ~ 0.35 kWh/kg LNG

- Capacities between 60-800 tons/day

- Designed for unmanned operation

- Delivery time: 18-22 months

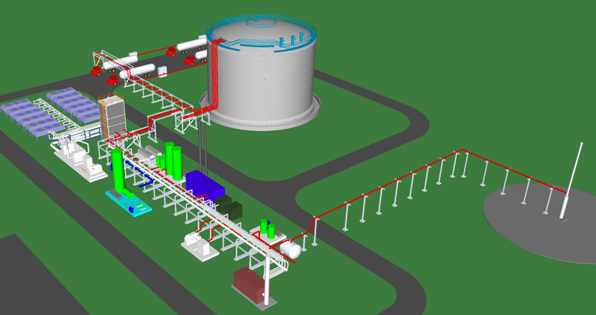

3D model for 400 ton per day plant

Applications

In areas where gases previously were not environmentally friendly and competitive energy sources, small-scale liquefaction plants open new market opportunities for the development of local or regional gas distribution networks.

In addition, small-scale LNG is also highly interesting as a price-competitive and environmentally friendly fuel for ships, trucks, and the general industry.

Cost and energy efficient small scale LNG plants also open possibilities to monetize previously stranded gas sources, such as pipeline gas, well gas or flare gas.

The Kollsnes II 240 ton per day plant

Key benefits

The benefits of Wärtsilä’s reversed Brayton cycle liquefaction technology include:

- Low power consumption – reduced OPEX

- The nitrogen-based cooling cycle reduces complexity and increases ease of operation and offers high inherent process safety

- High availability

- The refrigerant (nitrogen) is produced directly from air on-site. No logistics or complex makeup system connected to refrigerant handling

- The refrigerant is always in the gaseous phase, meaning no liquid levels to control and no risk of maldistribution on heat exchanger headers

- Installation is simple and time-efficient, as all equipment comes as ready-made modules. No stick building on site

- Compact technology – small footprint required

- The technology is robust, reliable, and easy to operate

- Capacity control is easy and with the fast response – within minutes

- Easy start-up and shut down of all systems

- Simple energy supply, only electric power needed

- Smaller plants are designed for unmanned operation

- No handling of chemicals required

- Our design provides a ZERO FLARE solution. During normal operations, hydro-carbon losses will be zero.

Downloads

Contact our 24/7 customer support at +47 815 48 500. For spare parts, please e-mail us with the equipment serial number or the name of the installation at moss-spares@wartsila.com (Inert Gas Systems) spares.wgs@wartsila.com (all other products)

For technical support & service, please email us with the equipment serial number or the name of the installation at services.wgs@wartsila.com.

Equipment serial number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.