Wärtsilä Shaft Generator Systems

Energy efficiency is the name of the shipping game these days. In addition to lowering operational costs, increased efficiency often translates to fewer emissions and can mean better compliance with environmental legislation.

Over the last few decades, shaft generator systems have become a more common option to help ship owners and operators achieve profitability in a sea of fierce competition and keep those waters cleaner for future generations. By connecting all the individual dots we make you more competitive.

“Wärtsilä has successfully delivered over 1000 shaft generator systems, further underlining our position as the world leader in this industry.

Shaft generators on board ships are driven by the main engine to supply power to the mains. The mains have to be supplied with constant voltage and frequency by the shaft generator whilst the speed of the main engine changes, i.e. when the vessel travels at different speeds or if the propeller speed strongly varies in heavy seas.

On ships with fixed pitch propellers, the speed is set via the propeller speed. If using controllable pitch propellers, the shaft speed and the propeller pitch are adjusted simultaneously in order to achieve optimum propeller efficiency in this so-called combinator mode. Even with this type of propeller, it is thus economical to use shaft generator systems with frequency converter for variable speed in order to permit combinator mode from pier to pier.

More than 60 years experience

Due to the numerous advantages of Wärtsilä Shaft Generator Systems, more and more vessels are equipped with them.

Key benefits:

- Reduce fuel consumption and costs

- Cut carbon emissions

- Reduce maintenance costs

- Reduce noise levels associated with onboard power generation

- Benefit from a payback time of 2 to 4 years, depending on system power

Meet requirements

All requirements of a ship‘s mains are met unrestrictedly while the shaft generator is operating:

- Unrestricted operation during main engine speed variations as the result of heavy seas and maneuvering

- Continuous parallel operation together (if 2 shaft generator systems are provided) and with diesel generator sets

- Generation of the required active and reactive power

- Selective tripping of short circuits without failure of the overall system

- Starting and shut-down of large consumers without inadmissible voltage and frequency fluctuations

- Operation, including synchronization, in the same way and with the same operating controls as on diesel generator sets

- Simple integration with automated power generation systems

Configuration

Wärtsilä’s shaft generator systems are designed with PWM frequency converters using modern IGBT technology. An additional synchronous compensator is no longer needed to generate the reactive power or the short circuit current, and is not required for the voltage control or for the filter circuits in order to lower the harmonics to admissible levels. This configuration has the following features and benefits:

- PWM frequency converter system with more economic power generation thanks to improved efficiency

- High mains quality with excellent harmonic distortion content due to high IGBT pulse frequency

- Just 2 components – shaft generator and the frequency converter panel – to be installed resulting in reduced volume and weight as well as lower costs for foundation, cables and cable work

- Water cooling of the power electronics with connection to the ship’s fresh water cooling system

- Geared shaft generator as standard brushless synchronous generator

- No step-up transformer for 400 V, 450 V, 690 V and 6,6 kV solutions

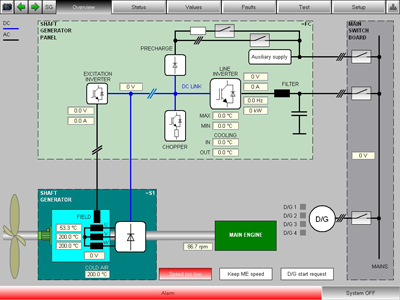

Test and simulation

The monitoring, test and simulation display integrated in the shaft generator panel permits monitoring of the system during normal operations. However, even with the main engine out of operation, the system can still be tested and virtually all system functions can be simulated. For monitoring, test and simulation, a colour display with a touch screen provides different mimic screens, such as OVERVIEW, STATUS, VALUES, ALARM, TEST and SETUP.

Improved availability

The shaft generator systems are equipped with a central, microprocessor-based computer for fully digitalized closed-loop and open-loop control and for test and simulation. Compared to earlier versions, numerous PC boards with relays for logic operations and elements for analogue and digital functions, are no longer required and have been eliminated. This drastic reduction in the number of components results in a substantial improvement in reliability and availability.

Better mains quality

The harmonic content at the output of the shaft generator system has to be effectively reduced to admissible levels according to the classification. Wärtsilä’s shaft generator systems are designed with a PWM frequency converter with a high IGBT pulse frequency, resulting in a higher than required mains quality without any measures, such as a filter circuit or duplex reactor. The THD in the mains voltage is below 5% in all operational states.

“Shaft generator systems are a valuable technical solution for ship owners who are looking for economical and cleaner electrical power generation during their sea voyage.

Adding a shaft generator will reduce emissions

Shaft generator systems will improve a vessel’s energy efficiency – and reduce emissions – because they use the main engine instead of auxiliary engines to generate electricity for use onboard.

You will find 50 more ways to reduce emissions in a fascinating eBook “51 great ways the maritime industry could cut its greenhouse gas emissions”. Learn more:

Operation Principles

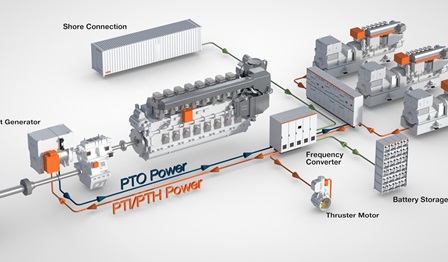

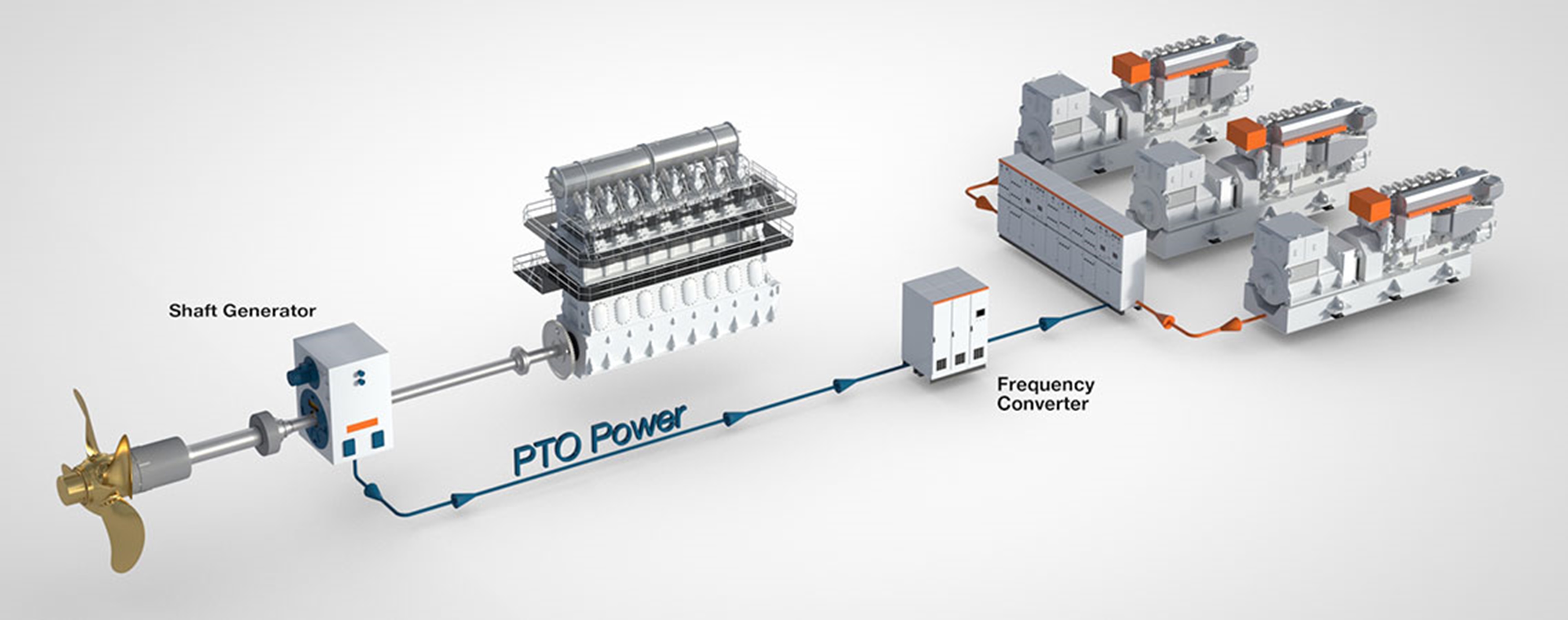

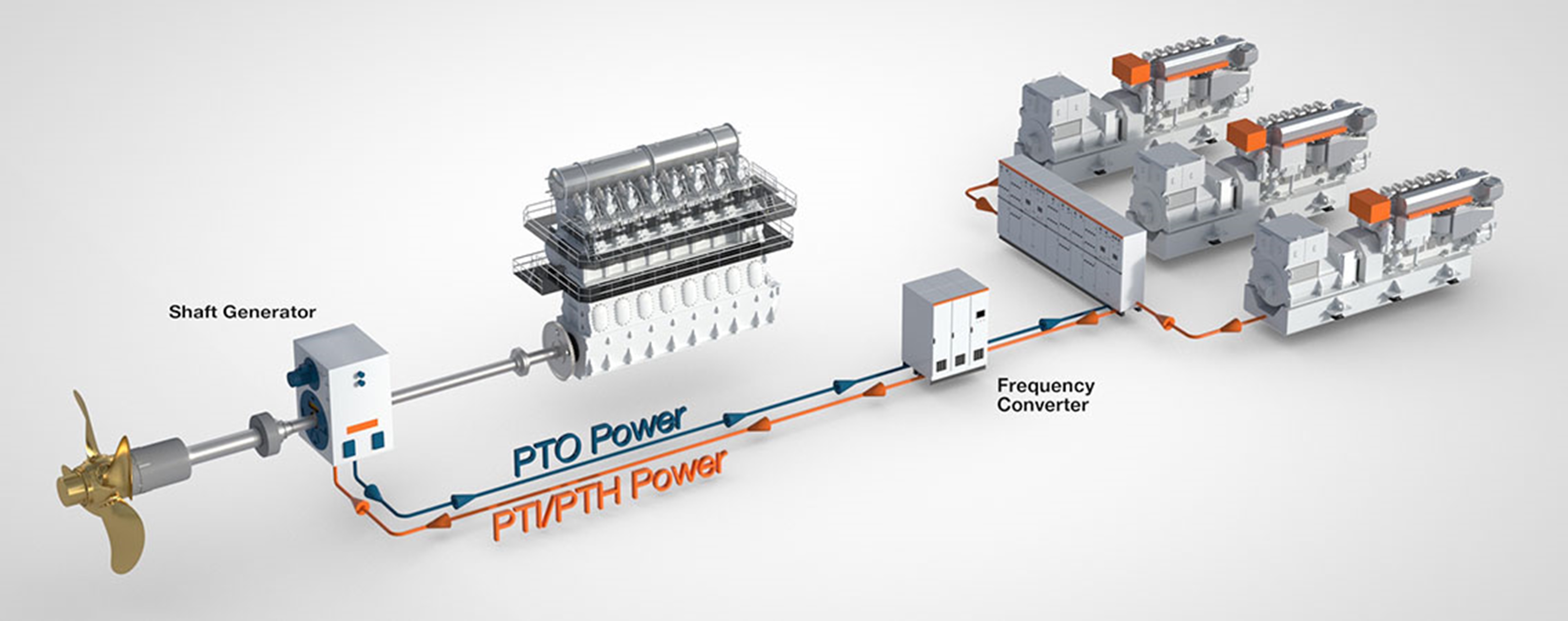

PTO

Shaft generator systems with frequency converters supply a three-phase current of constant voltage and frequency to the mains at variable main engine speeds. The useful speed range of the shaft generator can be defined from the ship’s operational requirements. For example, it is possible to select a shaft generator speed range of 60% to 100% of the main engine speed with a constant system output.

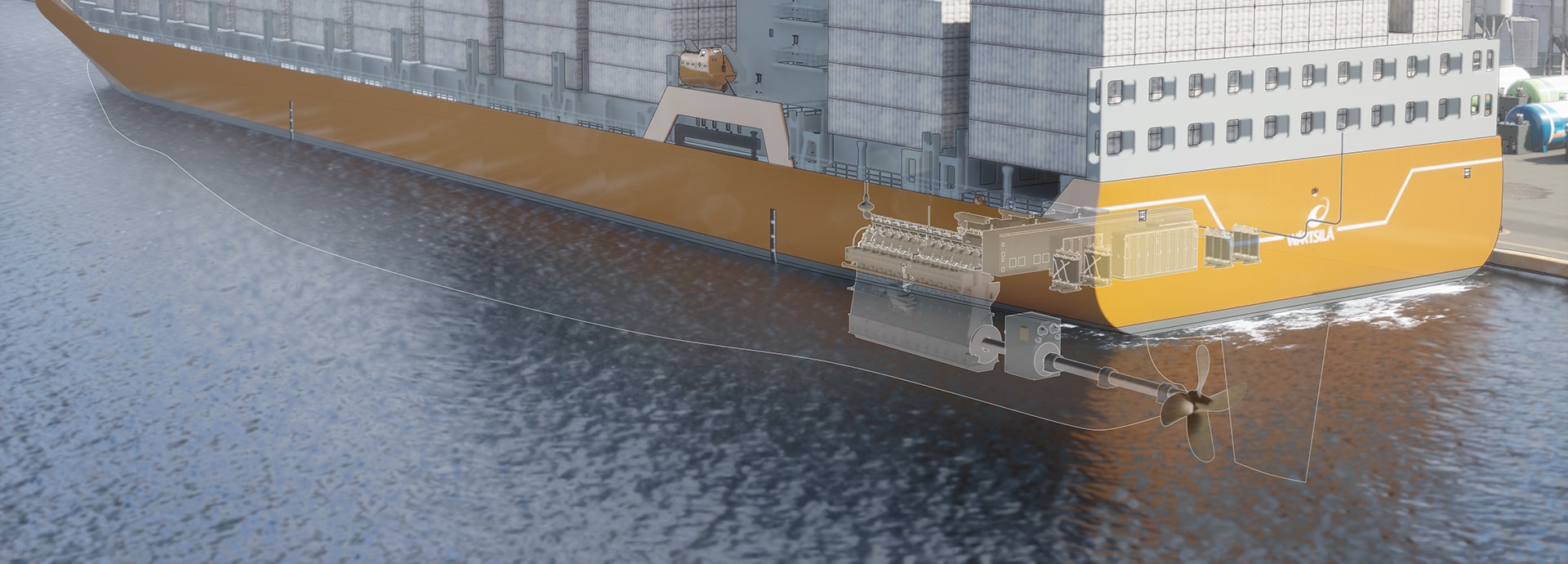

All shaft generator systems have one thing in common: The active power required for the mains is generated by the main engine. However, the shaft generator can be arranged and driven by the main engine in various configurations.

- The shaft generator is installed in the shaft line between the low-speed main diesel engine and the propeller. This configuration has a large air gap between the stator and the rotor, and without additional bearings has proven very successful as the most frequently used configuration. It is particularly simple and sturdy and requires little maintenance. Contrary to other arrangements, torsional vibration problems relating to the design and operation are not anticipated with this configuration.

- The shaft generator is operated via a power take-off by a reduction gear which is arranged between the medium-speed main diesel engine and the propeller. This is the usual and appropriate configuration for medium-speed main diesel engines.

- The shaft generator is operated via a tunnel gear unit installed in the shaft line between the low-speed main diesel engine and the propeller.

For additional shaft motor operation the diode rectifier is replaced by a PWM rectifier similar to the PWM inverter and the system control is adapted accordingly. With this configuration motor operation is provided as follows:

- Booster propulsion operation parallel to the main engine to enlarge the propulsion power and the ship’s speed

- Take home respectively take away propulsion operation as emergency propulsion drive without main engine in case of a malfunction of the main engine. For this mode the main engine has to be declutched from the propeller shaft

- The “Power Take In” mode is also possible to be fed by the main switchboard, which is supplied by auxiliary generator(s) and independent from a WHRS. Summarized this allows a maximum degree of freedom in power distribution between different units by using only one shaft generator converter.

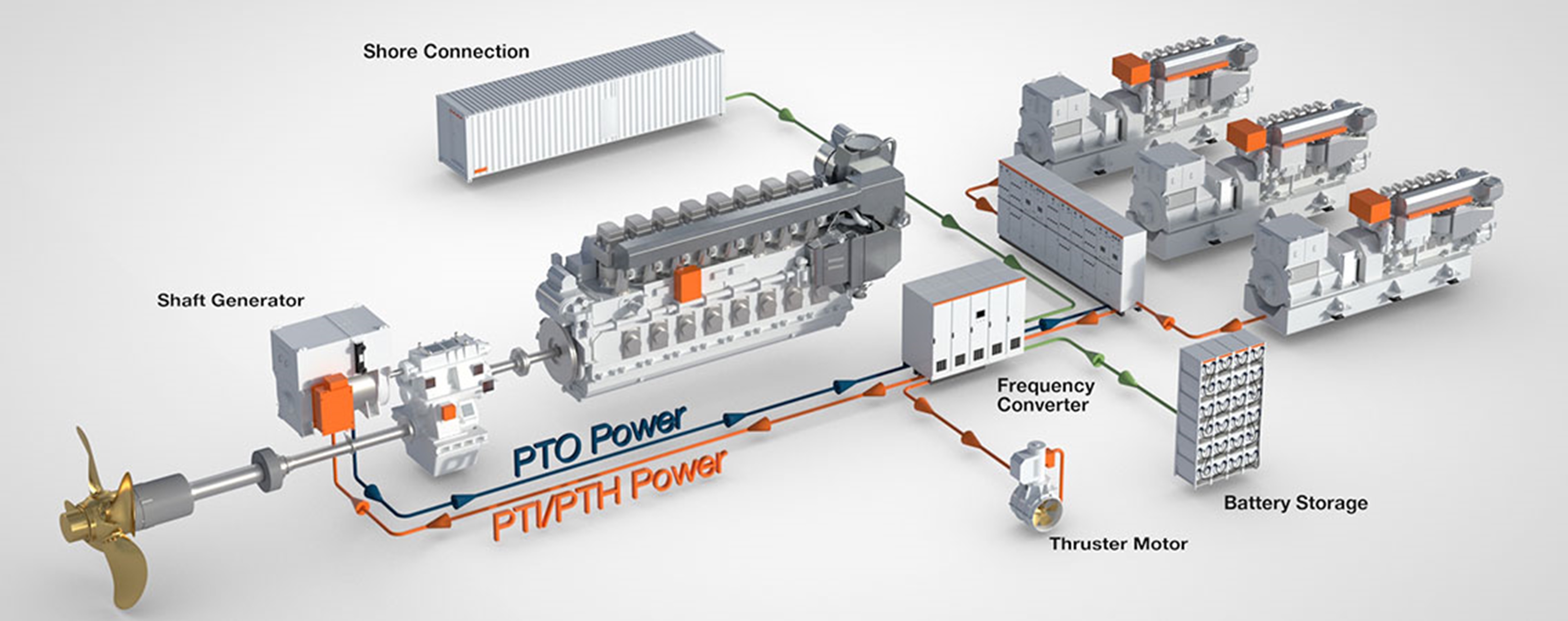

For shore connection with 50 Hz or 60 Hz the frequency converter of the shaft generator system can be used to adapt the shore frequency to the ship’s mains frequency. For that purpose the connection between shaft generator and converter is switched off and the converter is supplied (via cable reel, circuit breaker and transformer) from the shore. With this configuration the ship is full flexible for shore connection worldwide.

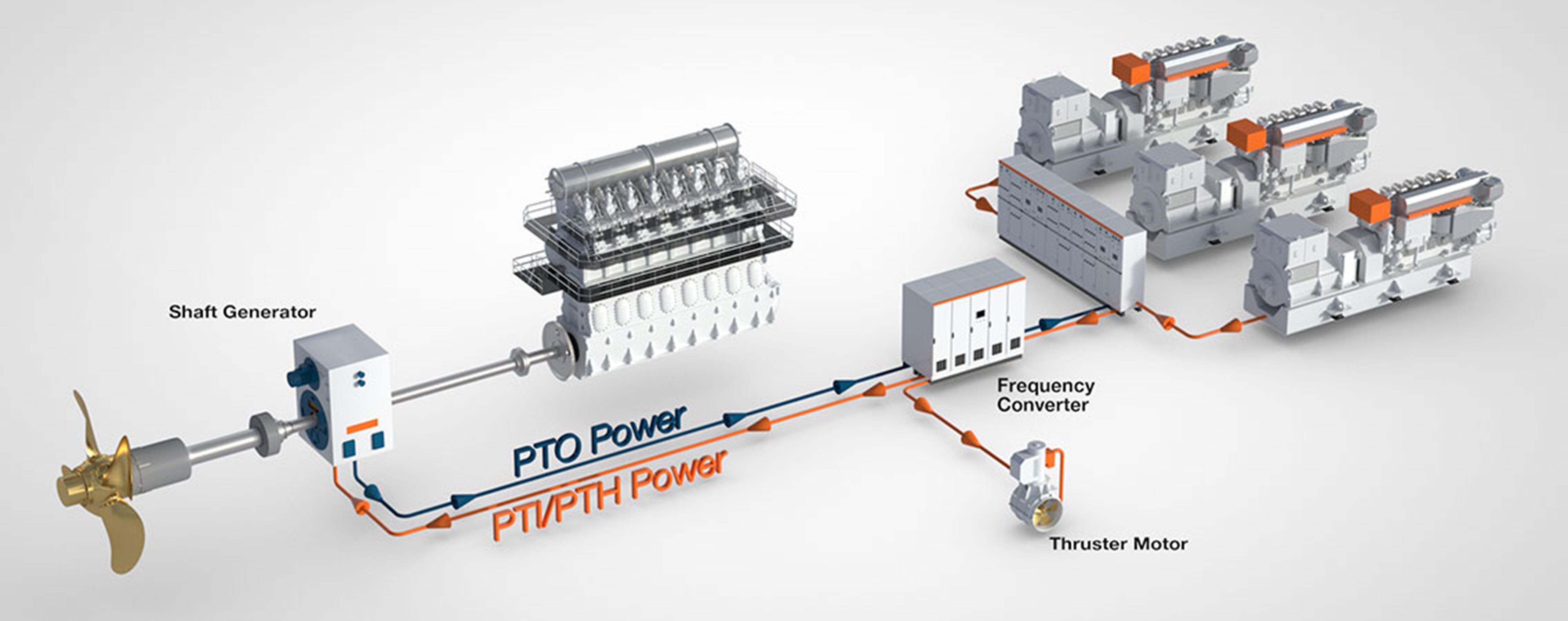

One of the latest features is the integration of the shaft generator converter with thruster. In conjunction with our partners, our shaft generator system further enhances overall operational efficiency and cost savings for our customers.

Customer stories

“Shaft Generators lower fuel costs, and reduce both maintenance and lubricant costs – for more profit and nature friendly benefits.