Future fuels in shipping – sustainable fuels development

Shipping plays a critical role in the global economy, transporting 90% of world trade. The challenge is that it also accounts for 3% of all greenhouse gas (GHG) emissions. To mitigate the environmental impact of shipping, the International Maritime Organization (IMO) has adopted a strategy, whose goal is to reduce GHG emissions from shipping by 50% by 2050, compared to 2008 levels.

Radical changes are needed to comply with the IMO target. Both vessel design and power generation are impacted. But the main challenge is fuel – the future fuels in shipping and the related global investments in their production and infrastructure.

A quick look into future marine fuels

This is a rundown of the 19 best picks on marine future fuel technology, with topics from ammonia to zero-emission energy distribution. It’s your quick guide to information to help you comply with regulations, save money, and hit your decarbonisation targets. All the alternative fuels knowledge you need in one place.

Sustainable fuels for shipping by 2050

How to decrease the environmental footprint of shipping? What are the key actions that will keep the shipping industry on course to achieve net-zero by 2050? Here are some answers: this research-backed report on future fuels in the marine industry reveals the key actions to take today.

Wärtsilä is leading the way in developing a wide range of engine and fuel gas supply systems to help ship owners navigate the route to reduced GHG emissions – whatever fuels they choose.

Given the modularity of modern engines this means that, as long as ship owners consider storage requirements, they can already plan to use new fuels on vessels being built today.

What is the difference between a carbon-neutral and zero-emission fuel?

Carbon-neutral fuel has no net carbon emission. Its production and use do not increase the amount of CO2 in the atmosphere. Examples include synthetic fuels made with renewable energy, and certain biofuels.

Zero-emission fuels release no CO2 when used because they do not contain carbon. Hydrogen is an example of a zero-emission fuel, but it will be carbon neutral only if it has been produced in a carbon-neutral way.

Future fuels and fuel-flexible engines development

Because new fuels are not readily available yet, it is difficult for shipowners and for the maritime industry to predict which is going to be the prevailing fuel in the future. All alternative fuels have their unique pros and cons. Therefore, each sub sector will have to map its own transition path to new alternative fuels.

Wärtsilä is investing in all the new fuels and developing flexible technologies for the benefit of the maritime industry. The company’s research on future fuels technology draws on its decades-long experience in building engines and supply and storage systems. This table summarises the existing fuel technologies and the ones under development.

Sustainable fuels – a great way to cut emissions

Adopting new sustainable fuels is a great way for the marine industry to cut harmful emissions. It is not the only way! You can find all of 50 great ways the maritime industry could cut its greenhouse gas emissions in a fascinating eBook!

What are future fuels in the shipping industry?

There is little certainty around the future of fuels in shipping. Flexibility will be crucial. And for many potential pathways the best solution is to develop engine and fuel handling solutions that already exist rather than create entirely new concepts.

One thing is clear. While the energy transition is in process, assets are unlikely to be operated on the same fuel for their entire lifecycle. And there are many types of sustainable fuels that have the potential to become future marine fuels.

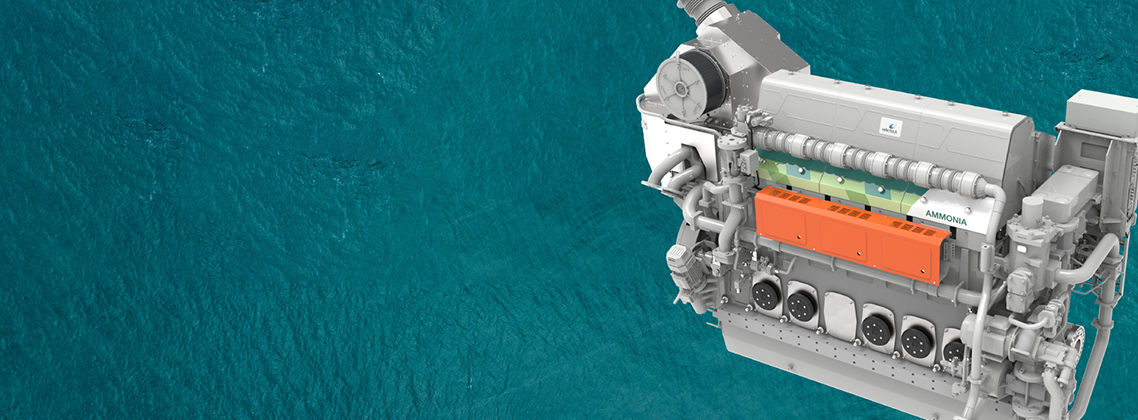

Ammonia

The exploration of ammonia as marine fuel is progressing fast. It is an attractive option because it does not have to be stored under compression or at very low temperatures. Its energy density is another positive factor. But it is also toxic and highly corrosive, which makes it challenging to handle, especially for passenger vessels. The current ammonia supply is fossil based, so ammonia would have to be produced in an environmentally sustainable way in the future.

Wärtsilä is not starting from scratch in this area. We have several years’ experience of designing cargo handling systems capable of handling ammonia for use on LPG carriers. On the fuel storage and supply side, we are participating in the EU project ShipFC to develop systems that will supply ammonia to fuel cells for Eidesvik Offshore’s supply vessel Viking Energy.

The collaborative Demo2000 project with Wärtsilä, Knutsen OAS Shipping AS, Repsol, Equinor, and the Norwegian Sustainable Energy Catapult Centre designed, constructed, and commissioned a full-scale environment for ammonia combustion, including storage, supply, and safety system – and successfully demonstrated that it works.

The fastest way to learn the key facts about ammonia is to download our handy one pager.

Could ammonia fuel maritime decarbonisation? Discover the facts about this promising future marine fuel in this comprehensive article: “Ammonia as marine fuel? It is easier if you do it smart”.

Wondering how you could get started with ammonia as fuel for your vessel? Download this white paper “Excited about ammonia as a marine fuel” to learn the most important things you need to know!

What does an ammonia-ready vessel look like? This article reveals the answers.

Marine biofuels such as FAME/MVO

Biofuels are an interesting alternative for the marine industry because of their potential as a carbon-neutral energy source. What are biofuels? How are they made? What do you need to know about them before deciding if they’re right for your operations? Get the answers from this article: “No more mysteries about marine biofuels – your top six questions answered”.

Wärtsilä has been continuously experimenting with many different biofuels since the 1990s. Over the past ten years, we have developed combustion techniques that further improve the fuel flexibility of our engines. The following engines can run on biofuels, for example:

- Wärtsilä 20 diesel and dual-fuel engines

- Wärtsilä 31 diesel and dual-fuel engines

- Wärtsilä 32 diesel and dual-fuel engines

- Wärtsilä 46 diesel and dual-fuel engines

Biofuels are largely compatible also with existing fuel supply and storage technologies. That is why biofuels can offer a simple, low-cost decarbonisation option for shipping.

Get your facts straight: download this handy one-pager on biodiesel.

Hydrogen

Wärtsilä’s dual-fuel engines and spark-ignited gas engines can already run on a fuel mix comprising between 15 and 25% hydrogen. This is one example of the fuel flexibility of dual-fuel engines. However, storage and fuel supply are the more challenging issue for hydrogen as fuel: its volumetric energy density is low, and it has an explosive and corrosive nature.

So, could hydrogen have what it takes to be the future marine fuel? This article summarises the pros and cons of hydrogen as a potential future fuel for maritime applications.

Liquefied Natural Gas LNG

Liquefied natural gas (LNG) is natural gas that has been cooled down to -162ºC (-260ºF). LNG is a great solution when transitioning to clean fuels because it offers significant greenhouse gas reduction potential: 5-21% reduction of greenhouse gas emissions, compared to heavy fuel oil. What else does it have to offer to ship owners and what should they take into account when considering it as an option? Learn the answers from an insightful article! LNG as fuel for ships: expert answers to 17 important questions.

LNG has a key role as a transition fuel and the first step towards decarbonising the maritime industry. LNG as marine fuel solution requires only existing infrastructure, which minimises the investment needed. Bio LNG also has the big advantage that it can be produced using many kinds of sustainable feedstocks, from manure via sewage residue to forest residue and many other types of waste.

Adopting LNG as fuel

Selecting LNG as a fuel option is not limited just to newly built vessels, as it is often feasible to convert conventional engines to be more flexible in fuel type, including LNG. This conversion does not limit the engine to using only LNG - it introduces true fuel flexibility where more than one fuel type can be used. These engines are known as dual-fuel engines.

Dual-fuel engines from Wärtsilä allow ships to be operated on either conventional liquid marine fuels or LNG. Dual-fuel engines allow ships to be operated on either conventional liquid marine fuels (MGO, HFO, Light Fuel Oil (LFO) or liquid bio fuel) or LNG. The switch between fuels can be made seamlessly during operation without loss of power or speed. This fuel flexibility enables compliance with emission regulations in controlled areas, while giving operators the possibility to choose the fuel according to cost and availability.

Whether a vessel can be converted to operate on LNG depends mainly on the space required by the LNG tanks and additional equipment required. In most cases, the most economical option is to convert the existing engines of a vessel, but installation of new dual fuel engines is in some cases a feasible option as well.

A complete vessel conversion includes the following elements:

- Engine conversion

- LNG tank(s) and foundation

- LNG/NG double walled piping

- Gas detection and fire suppression Inert plant/N2 storage and control air

- Bunkering station(s)

- Automation and control system

- Exhaust pipe gas burst disc(s)

- Gas compression system.

Learn more about fuel conversions for 4-stroke and 2-stroke engines:

How to minimise methane slip

Although LNG is a great solution for the marine industry, it is not perfect because the methane leakage during production and combustion impacts the GHG footprint of LNG. Learn more about this in a helpful article: “How to be smarter about methane slip – right now”.

Wärtsilä has already reduced methane leakage from its engines by 85% over the last 20 years, and we continue to reduce it further with new combustion technologies.

Take advantage of the developments and opt for a methane slip reduction upgrade for your existing engines. The upgrade is quick and easy and can cut methane slip by up to 65% depending on the engine type and load.

References

Methanol

Methanol is one of the key components of decarbonisation in the maritime industry. What are the advantages of methanol as fuel? What are the issues that ship owners and operators should consider before adopting methanol? This article has the answers: “Methanol as marine fuel – is it the solution you are looking for?”

Methanol engines

Wärtsilä is one of the few marine engine builders with experience in methanol engines. This page summarises everything you need to know about adopting methanol as fuel. It has helpful information for you about methanol conversions and about methanol engines for newbuilds.

Discover the portfolio of methanol engines for marine applications. The most popular methanol engine type, the Wärtsilä 32 Methanol engine is in deliveries. More ship engines in different sizes are in development and the broader portfolio of methanol engines will gradually become commercially available in the near future.

Now it is time to design your pathway to decarbonised operations and choose a methanol engine for your ship.

The Wärtsilä 32 Methanol engine is reliable and efficient. It can operate on a wide range of liquid fuels – from heavy fuel oil to methanol fuel. It is available as a retrofit and as a newbuild solution. Choose Wärtsilä 32 Methanol because it offers you a flexible pathway towards the decarbonised future.

References

Examples of customers who are already reaping the benefits from methanol-powered operations.

The engine on the Stena Germanica ro-pax ferry was converted to a fuel-flexible setup in 2015. The conversion was a success, and the ferry has been running mostly on methanol fuel since then.

Van Oord is accelerating the energy transition with its green ship fleet. Why did Van Oord choose methanol for their new offshore wind installation vessel?

Why is fuel flexibility so important?

Fuel flexibility and the ability to convert for fuels is crucial if you want your operations to continue uninterrupted. Your best choice is a set-up that does not depend on the availability of a single fuel type. At the same time, you will want to ensure the environmental performance of your vessel or fleet.

The requirement for flexibility applies to newbuild vessels and existing assets alike. IMO has set stringent targets to reduce greenhouse gas emissions. Much of the reduction must come from vessels already in service.

Watch one of these webinars to learn more about future fuels.

Insightful articles

These handpicked articles will further build your knowledge of sustainable, future fuels in the shipping industry.

Choose your path to future fuels with Wärtsilä

As the need for fuel conversions increases, Wärtsilä’s customers can draw on long experience of successful retrofits for sustainable fuels. The engine and fuel storage upgrades required for using LNG are already well-established technologies and have been executed across several vessel applications. Wärtsilä also has more than half a decade of experience gathered from converting diesel engines for methanol. For other fuels, including ammonia and hydrogen, solutions are under research and development.

When moving towards a complex fuel future, Wärtsilä’s goal is simple: to continue to be a provider of complete fuel supply and engine solutions for all future and alternative marine fuels.