Future-proof flexible solutions for bulkers and tankers

Wärtsilä’s solutions for bulk carriers and tanker vessels help you reduce fuel costs and optimise maintenance processes. This will improve the profitability of your vessel while enhancing its resale value.

Wärtsilä focuses on flexibility when identifying the right solution for you to create the optimal path towards decarbonisation. These solutions will ensure compliance and allow you to strike the perfect balance between performance and flexibility.

How to meet the key challenges facing large bulkers and tankers

Large tankers and bulkers (60,000 dwt and above) have diverse operating requirements based on cargo type and sailing route. These vessels usually sail point-to-point transoceanic routes, and the demands for propulsion and electrical power systems are different during idling, ballast and cargo operations.

Owners and operators of bulkers and tankers have to optimise their CAPEX and OPEX to be profitable and maintain a competitive edge. At the same time, regulations such as the Energy Efficiency Design Index (EEDI), Energy Efficiency Existing Ship Index (EEXI) and Carbon Intensity Indicator (CII) have led to a decrease in the average operational speed of bulkers and tankers from 12 knots to 11 knots. This change is reflected in the lower installed propulsion power in newbuilds.

Wärtsilä Part-Load Optimisation (WPLO)

The traditional propulsion setup for large tankers combines a fixed-pitch propeller (FPP) with a single two-stroke main engine dimensioned to cope with higher trade speeds and adverse weather conditions. Vessels with this setup have been slow steaming in recent years to reduce operating costs and many of them have had to apply Engine Power Limitation (EPL) solutions to comply with EEXI regulations. Ever stricter emission legislation and market-based measures such as the EU Emissions Trading System (EU ETS) will necessitate further speed reductions. As a result, some vessels may have to slow down to such a degree that they are no longer able to sail at the speeds the market demands.

Wärtsilä Part-Load Optimisation (WPLO) is a bespoke engine tuning and turbocharger rematching solution that safeguards competitive voyage speeds while ensuring that the vessel complies with EEXI. WPLO also reduces fuel consumption and emissions, which helps to improve the ship’s CII rating. Propulsion optimisation solutions and energy-saving devices from Wärtsilä can further enhance the effectiveness of WPLO.

Alternative fuels

For existing bulkers and tankers, optimising engines and propulsion solutions alone will not be enough to reach the ever-tightening regulatory targets for decarbonisation. Future fuels must be part of a long-term decarbonisation strategy.

Learn more about methanol engines by watching this webinar: New methanol engines: how will they power the future?

Learn more about the Wärtsilä 25 Ammonia engine, the first 4-stroke ammonia engine for ships.

Convert your 2-stroke diesel engine to run on future fuels: Fit4Fuels, an innovative retrofit technology platform.

Onboard carbon capture and storage (CCS)

It is possible to capture CO2 directly at the source with an onboard CCS system. This is one of many options to reduce your ships’ greenhouse gas emissions, and it is suitable for both existing and newbuild vessels.

Maintenance

When your vessel is well maintained and has a clean hull, you save fuel and generate less emissions.

Well-planned preventive maintenance is vital to ensure smooth day-to-day operations and cost-effectiveness, while high-quality reactive maintenance reduces unplanned downtime. Wärtsilä offers both so you can focus on your core business.

Genuine spare parts for your vessel delivers important benefits such as quality assurance and guarantees not available with non-original parts.

Shore power

Shore power solutions allow you to plug your vessel into the onshore electricity grid when in port. The FuelEU Maritime regulation requires all EU ports to have a shore power connection from 2030. Plugging into shore power gives bulkers and tankers the option to reduce the number and size of installed auxiliary gensets.

Wärtsilä Smart Propulsion System

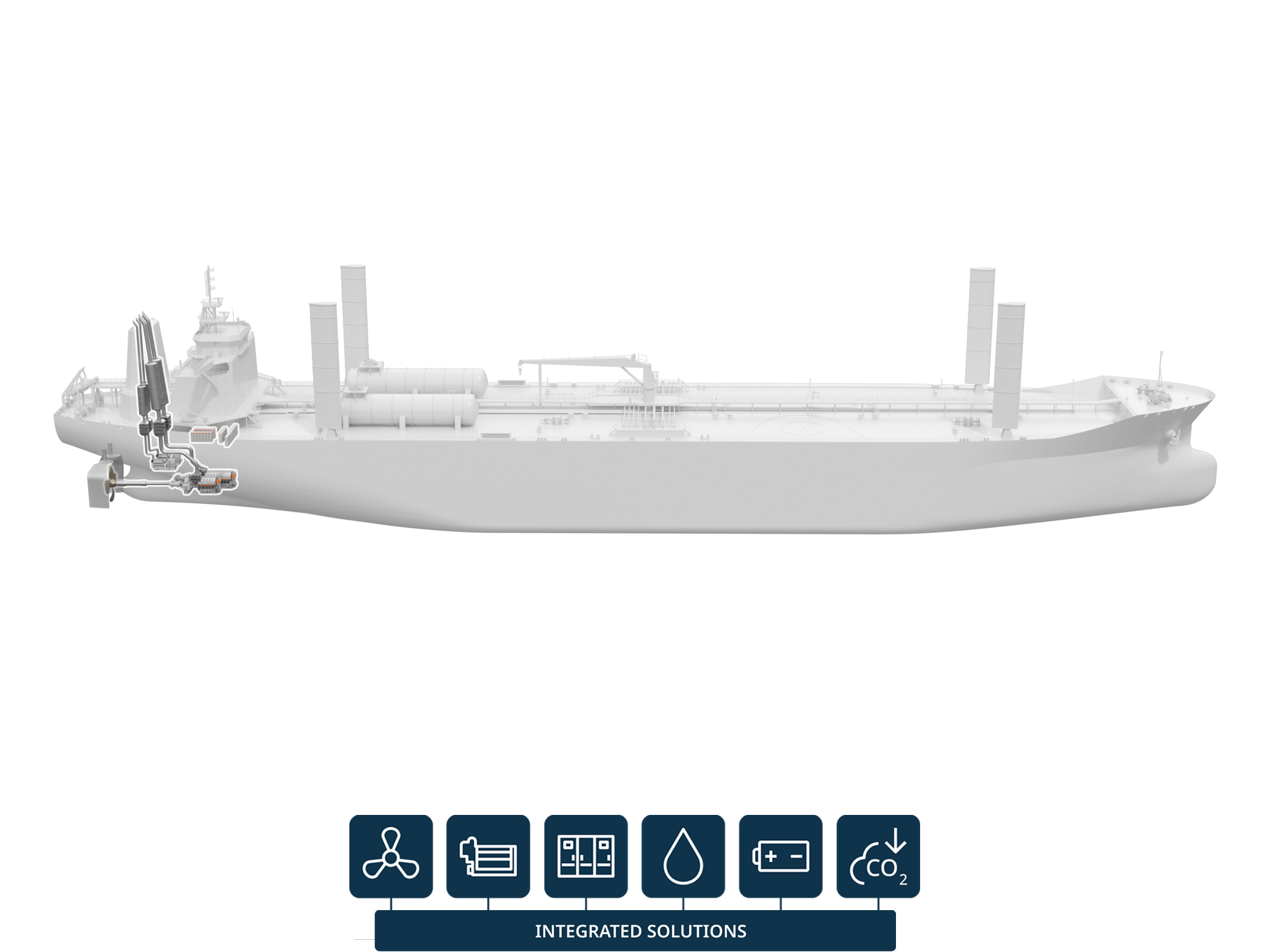

Wärtsilä’s Smart Propulsion System brings more flexibility to tankers and bulkers and offers maximum efficiency. It includes:

- Wärtsilä medium-speed main engines driving a single controllable pitch propeller (CPP)

- A shaft motor/generator (PTO/PTI)

- A battery-based energy storage system

- An auxiliary genset.

This setup can be further improved with the addition of GATE RUDDER™ by Wärtsilä, an energy saving solution that improves thrust performance and manoeuvrability.

Hover over or click on the symbols to reveal more information about the six parts of the integrated solution.

Smart propulsion system benefits

A configuration with two medium-speed main engines connected to a twin-in single-out gear with two power take-offs (PTO) and a single CPP will offer nine important advantages over conventional propulsion arrangements.

- Speed and cargo-handling flexibility – The preferred main engine can be run with the lowest possible specific fuel oil consumption (SFOC) while still ensuring sufficient power is available for cargo handling operations and to cope with adverse sailing conditions.

- Equipment flexibility – Wind-assisted vessels with a GATE RUDDER by Wärtsilä installed can adjust their drift and direction and improve overall performance. Wind-assisted operations should be supported by the most preferable main engine alternative. If required, a range of equipment is available according to owner choice.

- Fuel flexibility – Wärtsilä can deliver complete alternative fuel-capable solutions including engines and fuel handling and storage systems.

- Increased efficiency – A larger or optimised propeller with a geared solution and lower propeller rpm reduces fuel consumption and increases overall efficiency.

- Hybrid operation – The batteries in a hybrid propulsion system provide spinning reserve and peak shaving to ensure the engines run at optimal load at all times. The energy management system (EMS) optimises energy flows between producers and consumers to achieve the best performance in all operational modes.

- Shore power – When in port the vessel can cover its hotel load and the power requirements of cargo loading and unloading operations using a shoreside power connection.

- Sailing flexibility – Ballast voyages can be achieved using a single main engine, reducing fuel consumption and emissions.

- Cargo space – With lower installed power requirements the engine room can be reduced in size, freeing up valuable payload space.

- Redundancy – Two main engines provides full redundancy.

System operational modes

Solutions

Customer cases

Hand-picked press releases

Take your easiest step towards profitable, decarbonised operations – get in touch and let’s discuss your needs and options!