Solutions, services and expertise for dredgers

Dredgers operate in harsh environments and extreme temperatures. Wärtsilä solutions meet the needs and can handle the long operational hours, even when the equipment is constantly running at maximum power.

References

From the earliest times of diesel engines, Wärtsilä equipment and systems have been installed in complex vessels such as dredgers. Our power solutions continue to be the choice for dredgers built by the world’s leading yards. For example, these dredger owners have already gained significant advantages from choosing Wärtsilä.

DEME Group – To stay ahead of tightening emissions limits and deliver on its ambitious sustainability promises, global marine solutions provider DEME approached Wärtsilä. The resulting cooperation led to the creation of Wärtsilä’s GHG reduction package for its 34DF dual-fuel engines.

UKD Marlin - When the engines in a dredger owned by UK Dredging were close to the end of their lifecycle, the solution was to re-power the vessel with new Wärtsilä W20 engines.

How to meet the key challenges facing dredgers

The top three challenges faced by dredger owners and operators are optimizing CAPEX and OPEX, maintaining profitability, and staying competitive in the market.

Dredgers are special vessels used to remove loose material such as sand, silt, gravel and clay from areas such as harbours and riverbeds. Dredgers move between the trailing area where they are working and the unloading area where they offload the material from onboard hoppers.

To maximise the amount of material moved, dredgers sail at full speed most of the time. This means that vessel maximum power is configured for transit operation. During trailing operations power demands fluctuate widely to match the needs of onboard equipment such as engines, thrusters and pumps.

Three strong solutions help you meet these challenges: fuel-flexible engines, hybrid propulsion system and a battery-based energy storage system ESS.

Fuel-flexible engines for dredgers

Discover the continuously developing portfolio of powerful dual-fuel engines from Wärtsilä. Our fuel-flexible engines are a future-proof investment.

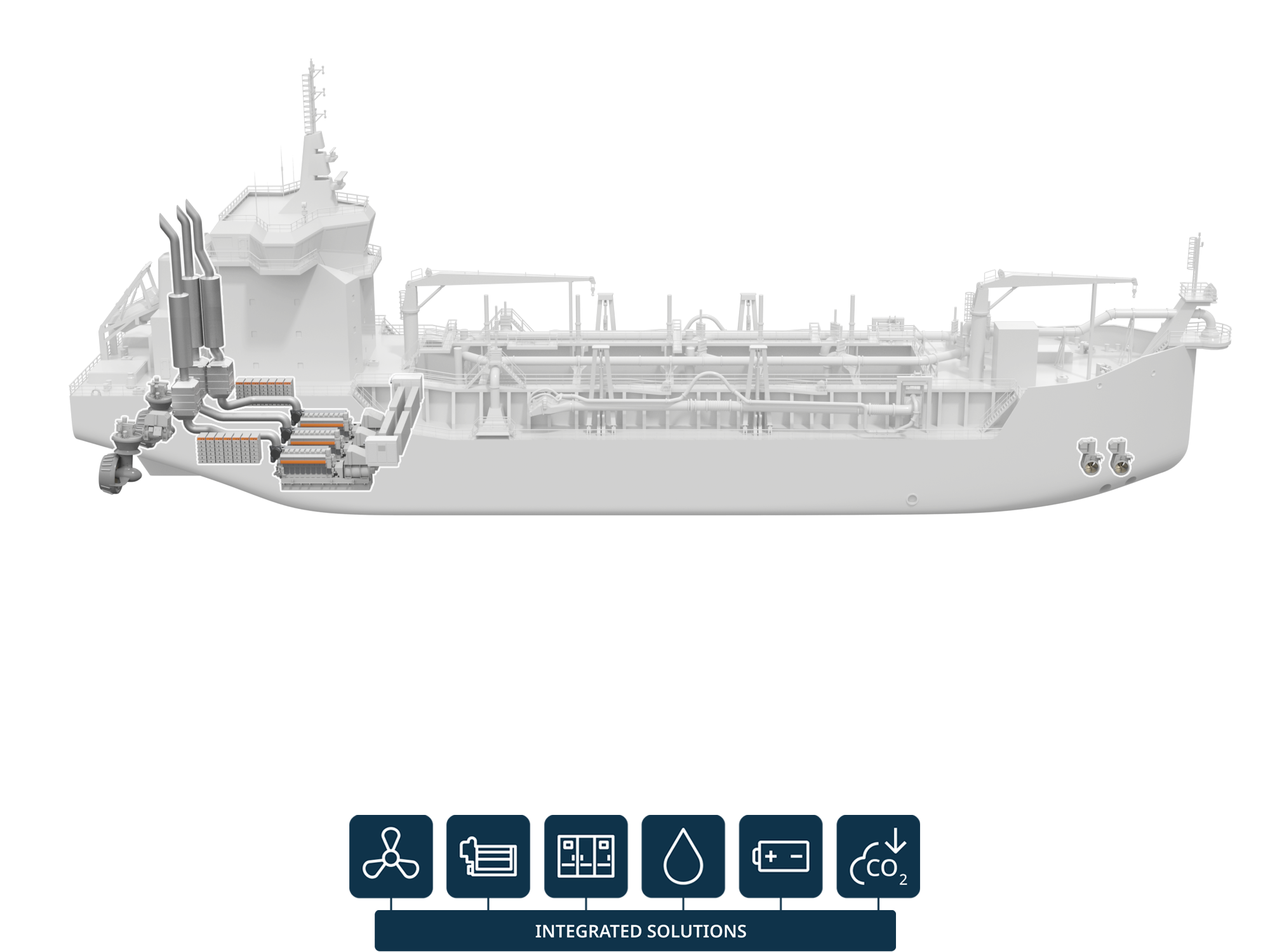

Wärtsilä hybrid propulsion system complete with ESS

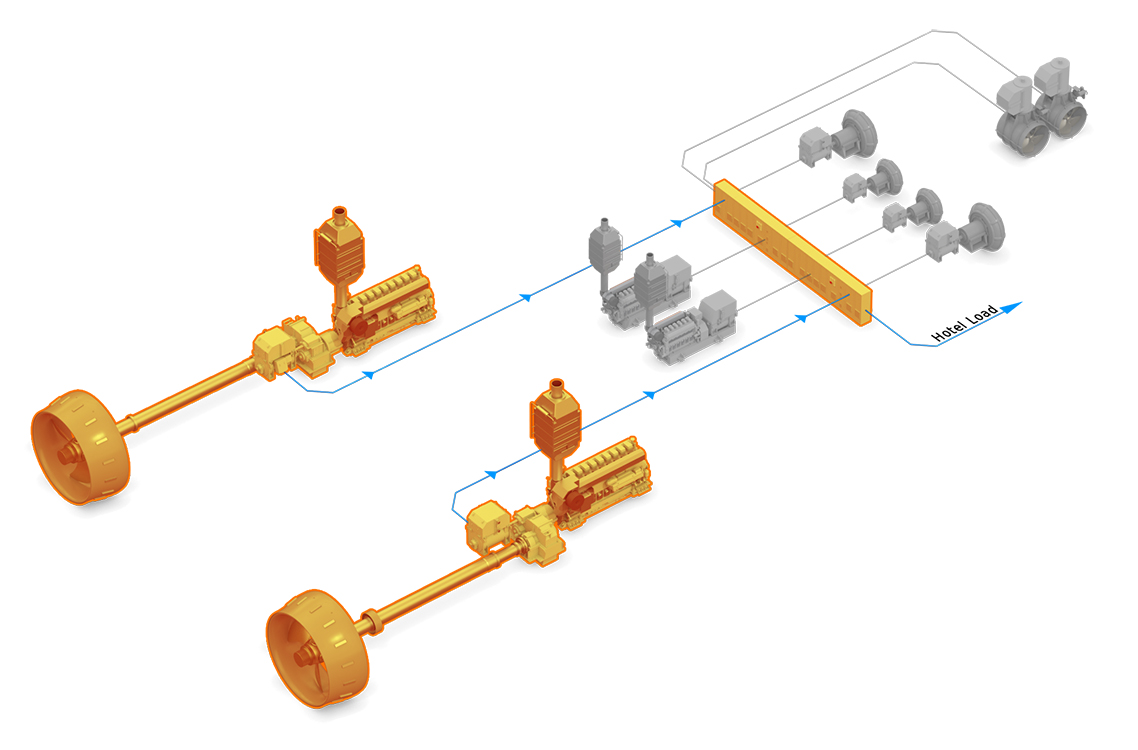

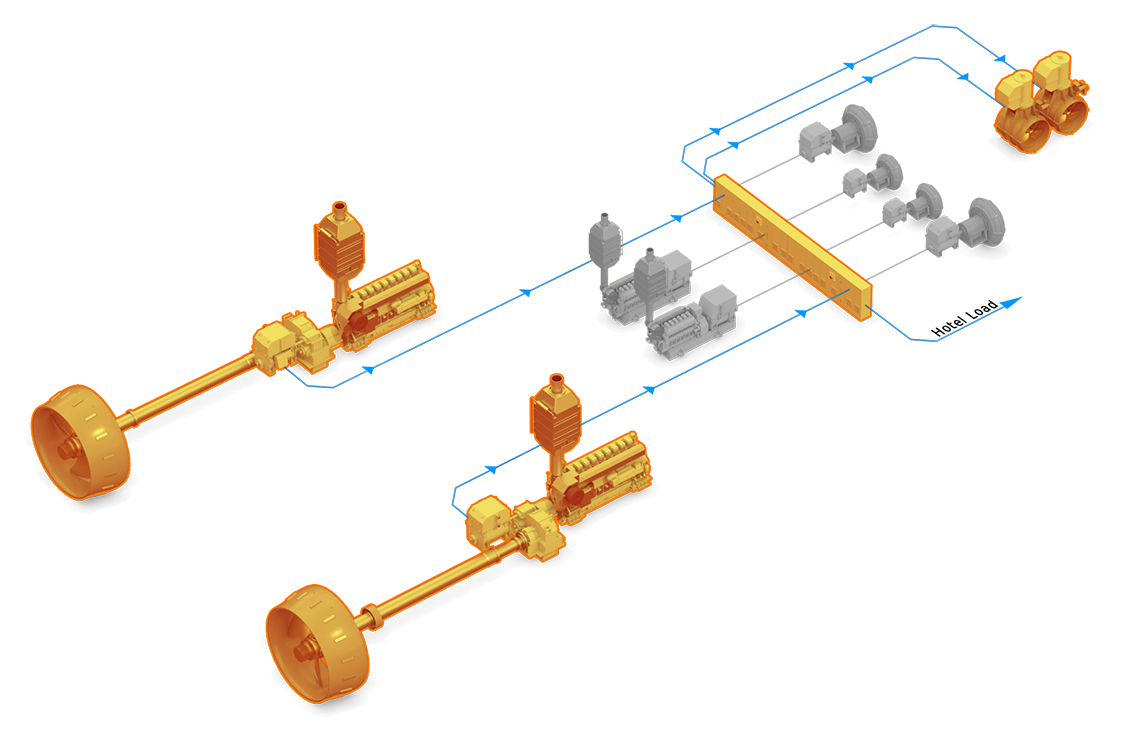

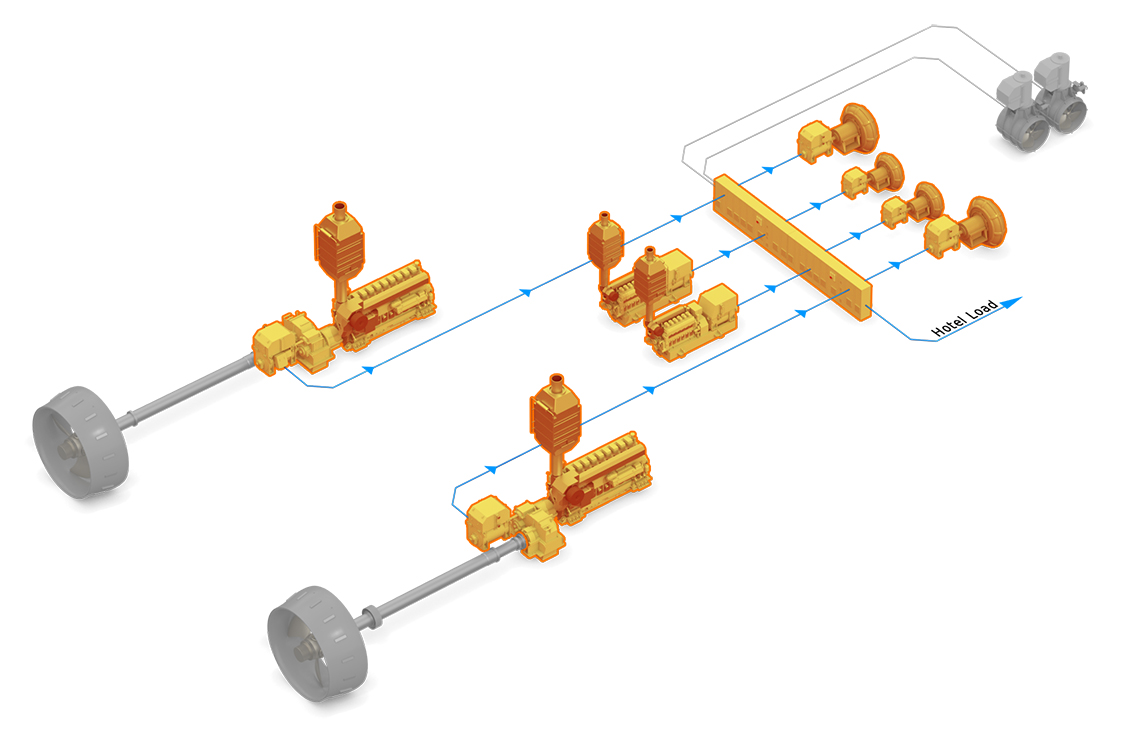

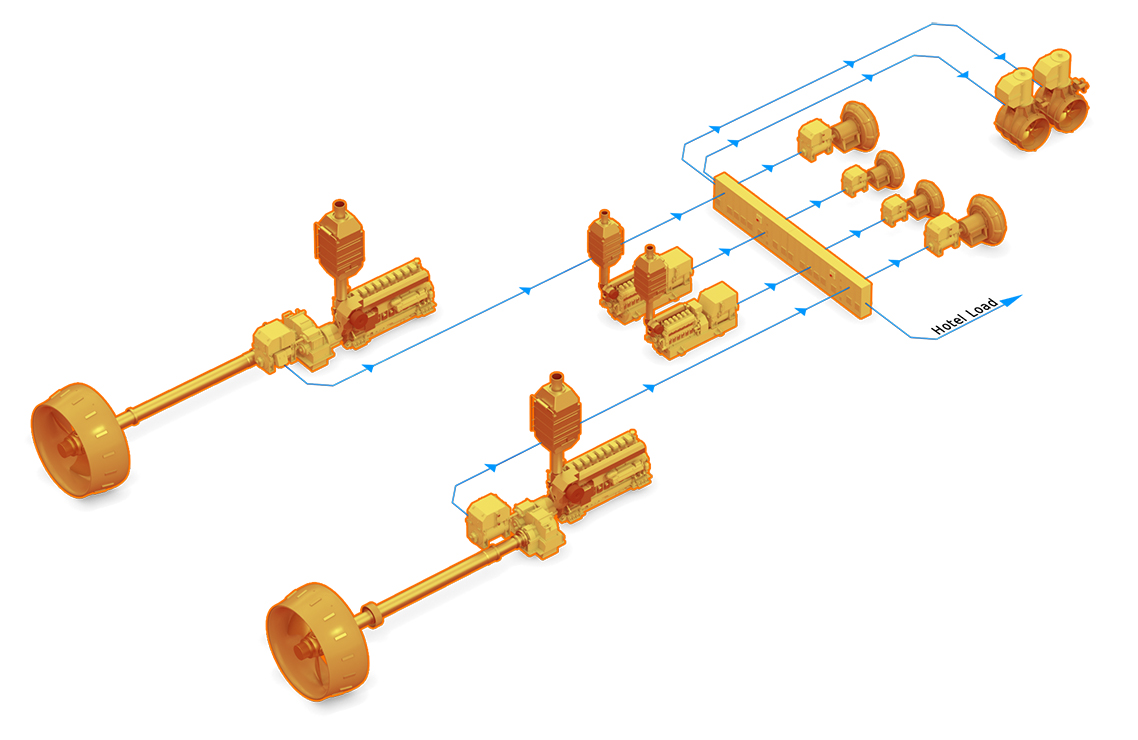

Because the power requirements depend on the operational mode, a flexible hybrid system offers many advantages. One example is the Wärtsilä hybrid propulsion system, which includes:

- a fuel-flexible medium-speed main engine

- geared propeller systems

- power take-off/power take-in (PTO/PTI)

- one or two auxiliary gensets

- a battery-based energy storage system (ESS).

An integrated energy management system (EMS) will ensure optimal operation under all conditions for maximum efficiency.

The battery-based ESS performs several key functions:

- Peak shaving: The ESS smooths out the power demand, avoiding drastic load variations. This allows the engine to operate more efficiently.

- Boost: The ESS can provide extra propulsion power when required.

- Reliability: The battery acts as spinning reserve, enhancing redundancy in case of system faults.

- Power storage: If the vessel has lifting equipment like electric winches, the ESS can store surplus power from lifting operations for later use.

- Lower emissions in port: Batteries minimise the need to use auxiliary gensets to generate power for cargo operations and to cover the hotel load, lowering emissions and reducing engine running hours.

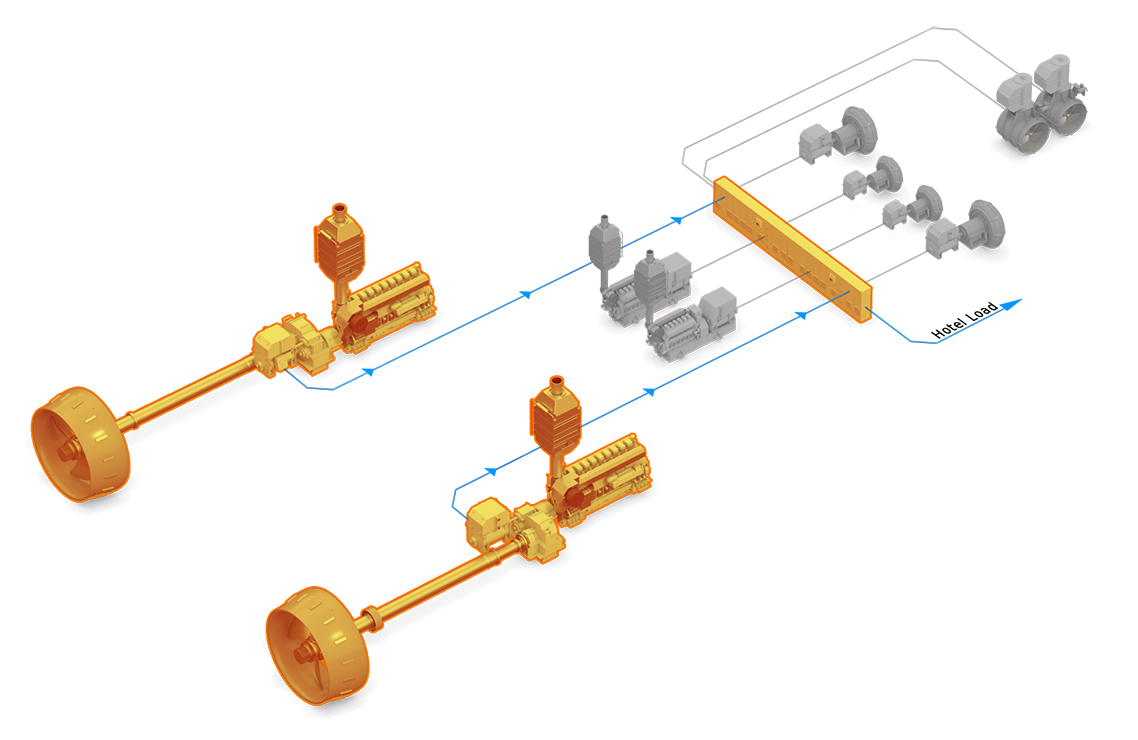

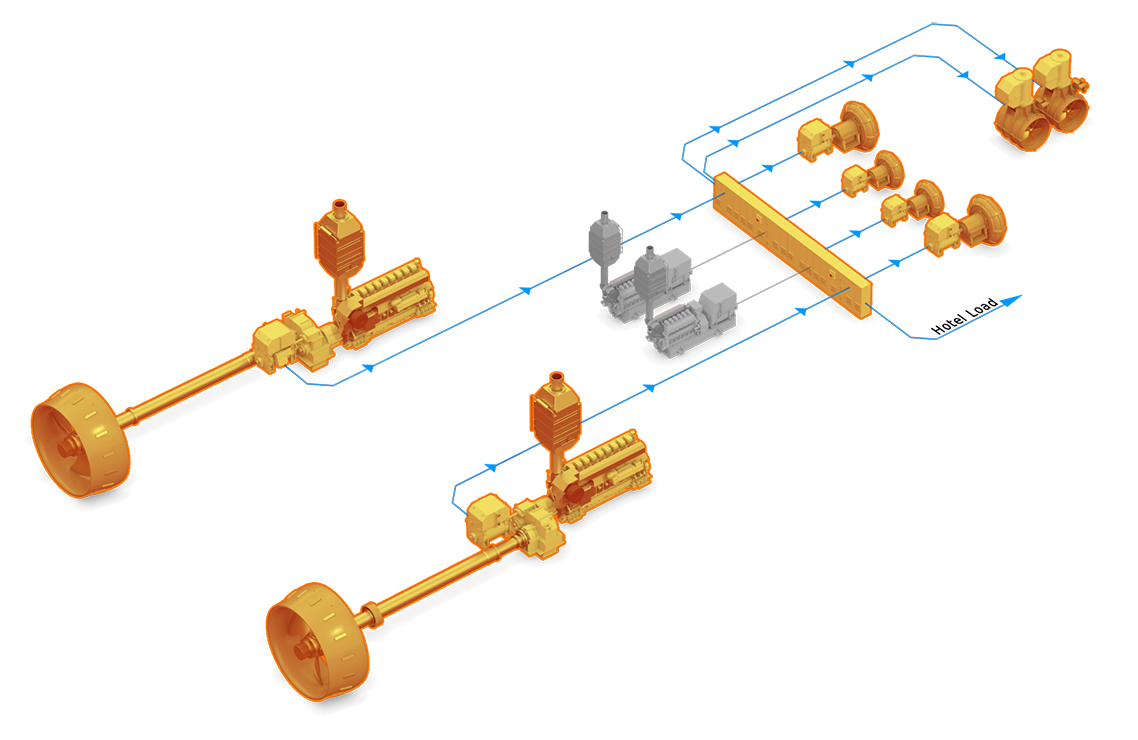

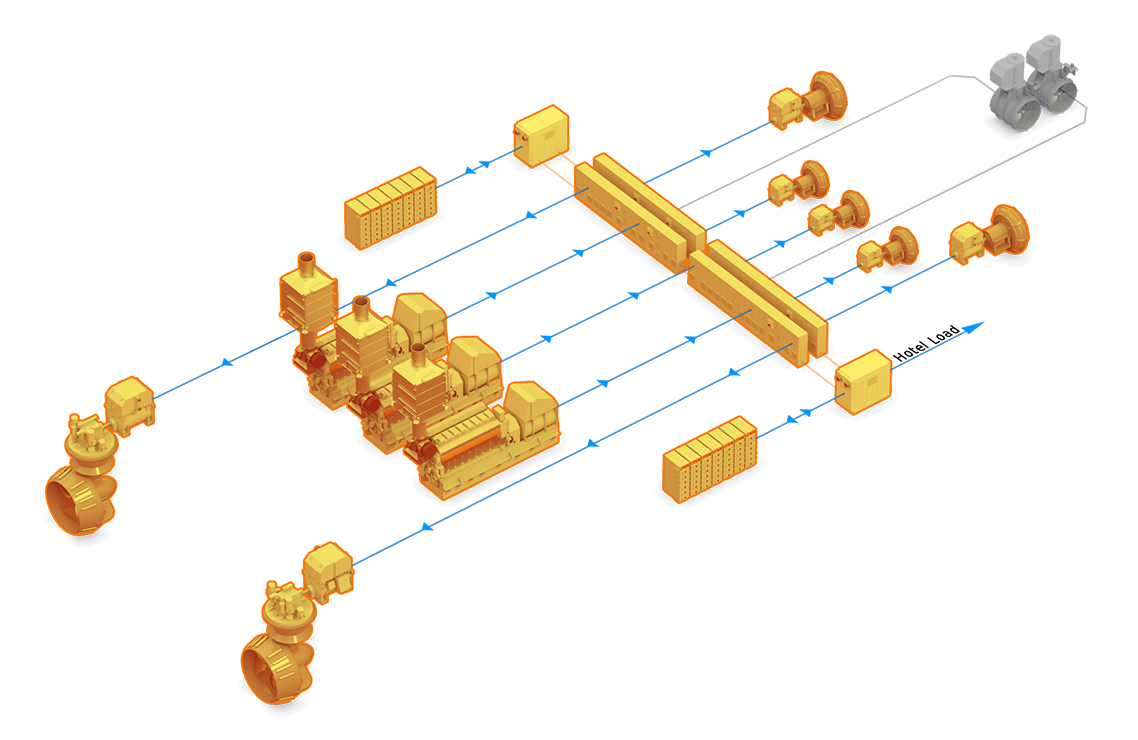

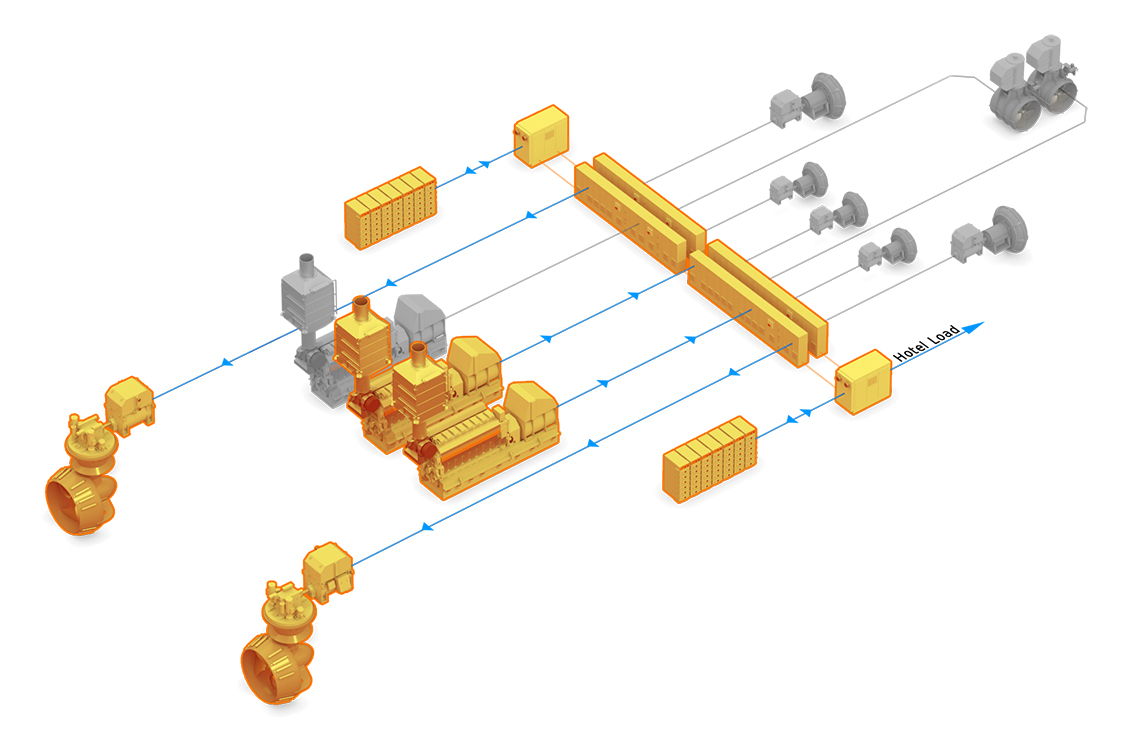

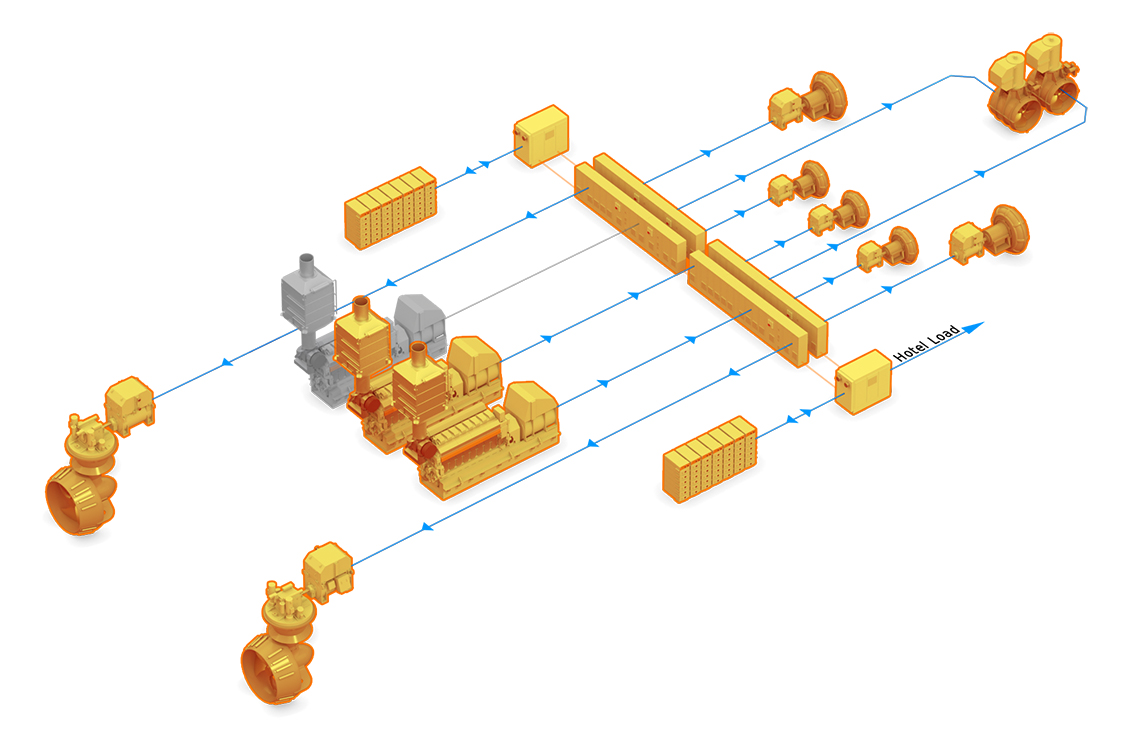

System operational modes

Mechanical setup

Electric setup

Essential services for dredgers

Maintenance and repairs

Keeping your dredger well maintained can save fuel. Wärtsilä offers a wide variety of maintenance and repair services, and you can focus on your core business.

Spare parts

Sourcing genuine marine spare parts from Wärtsilä as the OEM will deliver important benefits.

Managing your dredger’s lifecycle

A maintenance agreement means that your maintenance budget is predictable. Properly maintained vessels are more efficient, which helps you stay profitable.

Ruud Godeschalk - Area Maintenance Manager - Boskalis Dredging

Hand-picked press releases

Why choose Wärtsilä?

Maximum efficiency and minimum labour costs are essential for the successful operation of dredgers. Wärtsilä’s products and solutions are designed to match this requirement and are based on industrial state-of-the-art hardware components.

Wärtsilä’s dredger control technology allows control of the entire dredging process from one central station. All relevant data for the production process and cost-optimized control of the dredging operations are displayed to the operator.

Wärtsilä’s technical expertise is complemented by an open-minded approach to what dredging companies need and want.

Choose Wärtsilä's solutions to optimize your dredger's performance, reduce costs, and maintain a competitive edge in the industry. Contact us today to discuss your specific needs and find the best solution for your dredging operations.