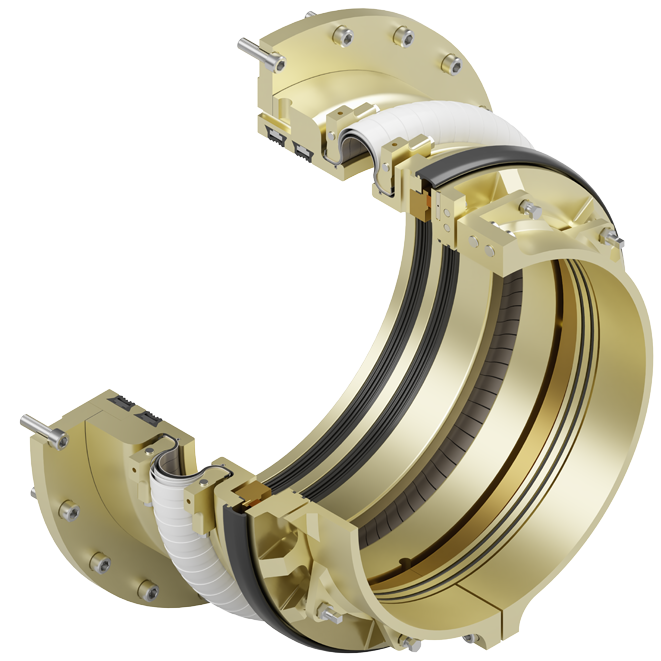

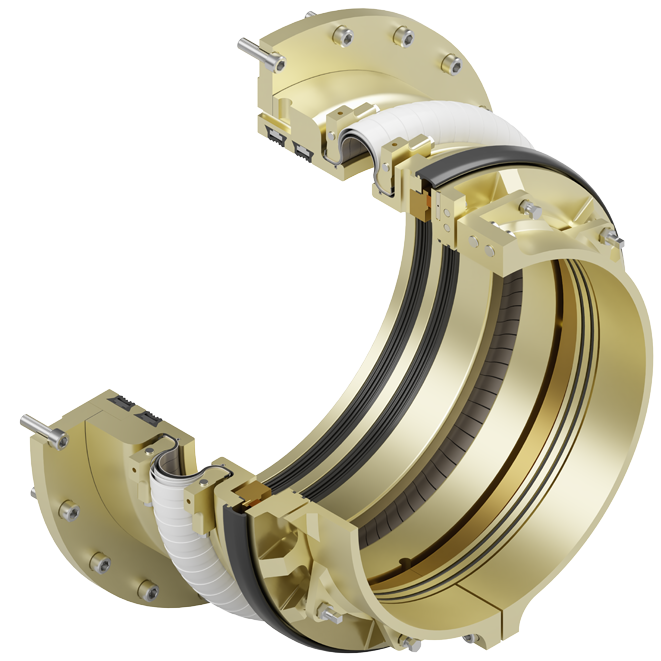

Wärtsilä Enviroguard M seals

The Wärtsilä Enviroguard M seals has long been the standard for naval and commercial applications, and for sensitive, harsh environments. With no maintenance between planned overhauls (up to 5 years), these seals supports ship operators in reducing operational expenditure and vessel downtime. In the event of planned or emergency maintenance, this can be completed afloat through the use of an inflatable seal, helping to reduce the time spent in docking.

These seals have an extensive fitted history spanning many years and numerous different vessel types. The Wärtsilä Enviroguard M seals can accommodate large and repeated axial and radial shaft movements, as well as vibrations.

Shock tested, reliable and environmentally compliant face seals

The Wärtsilä Enviroguard M seals are highly engineered seals, designed to support naval and commercial operations. In understanding these environments, our face seals are designed to provide enhanced resistance to abrasives and in brown water operations. Through continuous improvement, our seals have been regularly tested, updated and improved to deliver unprecedented benefits that provide real value to our customers. These include a double barrier inflatable seal that allows in-water maintenance and is designed with digital sensors, to enable condition-based monitoring.

The double barrier inflatable seals act as a physical barrier to prevent water ingress composed of at least two independent blocking methods - to exclude water flow between the internal diameter of the stern tube and the outside diameter of the propeller shaft. The use of a double barrier method reduces the risk of compartment flooding and any subsequent vessel damage.

The Wärtsilä Enviroguard M seals can be supplied either fully split, fitted with the shaft in place or partially split. The partially split option requires the shaft to be removed or split at the coupling to fit the unsplit parts, in most cases, the mounting ring and face carrier. Both options have split spare parts so they can be overhauled with the shaft in place.

Wärtsilä Enviroguard MA and MD Seal installation

How can we help?

Contact our customer support at sls247@wartsila.com for assistance with solutions related to the shaft line.

To enable prompt response, please indicate the Equipment Serial Number or the name of the vessel. Equipment Serial Number is taken from the equipment nameplate and includes all letters and numbers as given on the equipment nameplate.

For all other enquiries, please fill in the online form. Fields indicated with an asterisk (*) are required. We aim to respond within 1-2 business days depending on the scope of your enquiry.