Originally designed to run on LNG, MDO and HFO, the Dragon class vessels were meant to use LNG as fuel when trading ethane and other LPG cargoes. However, logistical challenges with LNG and extremely favourable price development of ethane led to the idea to use LEG cargo boil-off as fuel. Wärtsilä worked in close collaboration with Evergas and INEOS to make the world’s first ethane-powered marine vessels a reality.

In January 2013, Evergas was awarded a fifteen-year charter contract from INEOS Europe for the transportation of ethane into Europe from the US Mariner East project. Evergas, in turn, announced new-building contracts with Sinopacific Offshore and Engineering, China, for the construction of state-of-the-art, medium-sized, 27,500 cbm LNG multi-gas carriers.

In April 2013, Wärtsilä was rewarded a contract to Evergas to supply an integrated solution consisting of gas handling systems, dual-fuel main and auxiliary engines, and propulsion for three 27,500-cbm, multi-gas carriers. The installed engine power consists of two Wärtsilä 6L50DF main engines plus two Wärtsilä 6L20DF auxiliary engines. The vessels are capable of transporting a range of gases, including liquefied natural gas (LNG), liquefied ethane gas (LEG), ethylene and liquefied petroleum gas (LPG). In 2014, repeat orders were placed for an additional five ships, bringing the total number of vessels to eight.

In summer 2014, approximately one year before delivery of the first vessel, Evergas approached Wärtsilä with a new request: to evaluate the feasibility of burning ethane directly in the engines. The solution would eliminate the need to bunker LNG separately, and one could utilise LEG cargo boil-off directly as a fuel in the engine. Wärtsilä completed an initial feasibility study which indicated that it would be feasible for Evergas to maintain normal operations when utilising LEG as an alternative fuel to LNG. During the second half of 2014, Wärtsilä, in close collaboration with Evergas and INEOS, embarked on a joint engine development project to develop a LEG-optimised performance set-up for the Wärtsilä 50DF engine.

The first two Evergas Dragon Series vessels were delivered in July 2015. The Marcus Hook ethane export terminal, near Philadelphia, PA, USA, went into operation in March 2016, and the JS INEOS INTREPID became the world´s first vessel to carry export US shale ethane on 9 March, 2016. Wärtsilä completed successful LEG gas trials on INEOS INTREPID shortly after her arrival in Rafnes, Norway, and on 23 March, 2016, it became the world´s first ever ethane-powered marine vessel. On 1 September, 2016, the first ethane shipments also commenced from Enterprise’s Morgan’s Point, Texas terminal and the ethane receiving terminal in Grangemouth, Scotland began taking its first cargo in late September, 2016 upon the arrival of JS INEOS INSIGHT.

This article will highlight the development project for Wärtsilä 50DF-LEG engines and the main customer benefits for INEOS and Evergas with ethane-powered propulsion. Aspects related to the fuel and gas handling scope of supply are also summarised. Finally, the significant emissions reductions with the use of LEG, similar to those with LNG, are elaborated.

Fig. 1 - JS INEOS INSIGHT - member of the world's first series of ethane-powered marine vessels in Grangemouth, Scotland. Ⓒ INEOS 2016, reproduced with permission. All rights reserved.

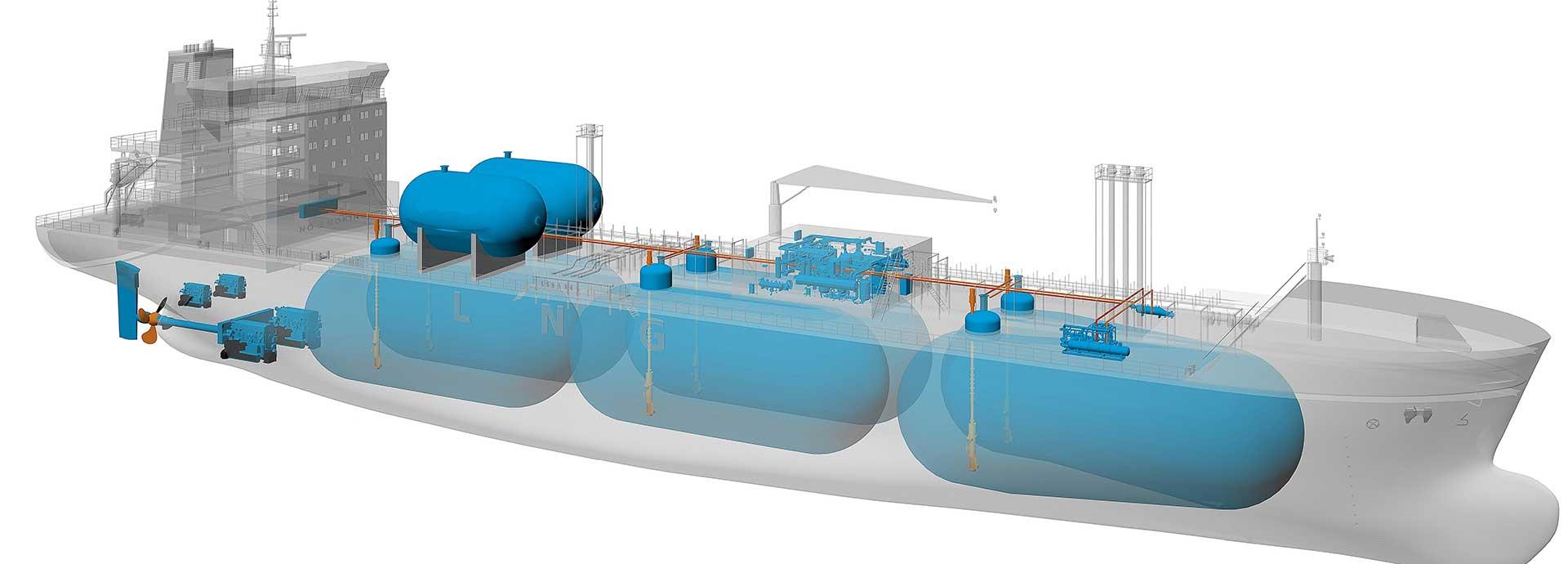

Fig. 2 - Schematic of the Evergas Dragon Series 27,500 cbm multi-gas carrier.

Test facility preparation

During early 2015, in a period of four months, Wärtsilä designed, manufactured and installed a pre-fabricated LEG gas vaporizer and mixing unit. The commissioning of the unit took place in March 2015, in Wärtsilä´s gas engine test facility in Bermeo, Spain.

Upon gasification, the LEG enters into a mixing chamber, connected to the local natural gas network, to facilitate controlled mixtures of ethane and methane of any concentration to enter the engine.

Evergas, with the support of INEOS, arranged delivery of 60 metric tons of LEG for engine testing. The fuel was offloaded from a European, short-route LEG carrier in Zeebrugge in February 2015 and loaded into three, 20-metric-ton, cryogenic transportation tanks.

Fig. 3 - LEG gas vaporizer and natural gas mixing station.

Fig. 4 - Offloading of ethane in Zeebrugge, Belgium – February 2015.

Development of the technical solution

The Wärtsilä 50DF engine is a four-stroke, dual-fuel engine operating on the Otto combustion principle when operating in gas mode. In practice, this means that a pre-mixed blend of air and fuel is compressed inside the combustion chamber until an external source of ignition starts the combustion. The optimal operating window of a lean-burn, dual-fuel engine is summarised in Figure 5.

Due to the fact that the request to utilize LEG came quite late in the project, the first engines for the Evergas Dragon Series already had been manufactured and were delivered to the shipyard as standard LNG-optimised, dual-fuel engines. Consequently, it was of utmost importance to find a technical solution that limited the overall changes to the engines and maintained maximum commonality with the standard, LNG-optimised set-up, in order to have a cost-effective and easy-to-implement, retrofit solution.

During the initial technical feasibility, Wärtsilä concluded that, even though the new combustion set-up would be optimised for LEG, the solution was still capable of using LNG in gas mode and MDO or HFO in diesel mode at the normal maximum continuous rating without any changes to engine hardware or software. Furthermore, the engine would be capable of running on any mixture of LNG/LEG, providing an extremely flexible, quattro-fuel-capable engine that can switch between HFO, LFO, LNG or LEG with uninterrupted power availability.

To better understand the technical actions taken to optimise the Wärtsilä 50DF for LEG, it is first appropriate to examine the actual fuel properties of LNG and LEG and understand their impact on the Otto combustion process. Table 1 summarises the relevant properties of LNG and LEG.

The lower heating value (LHV) of a gas represents the amount of heat released by combusting a specific quantity of the gas. Wärtsilä´s dual-fuel engines control engine load by managing the gas quantity admitted, through the utilisation of a Solenoid Operated Gas Admission Valve (SOGAV). Due to the higher volumetric LHV of ethane, no modifications were needed to the standard SOGAV on the Wärtsilä 50DF engine.

Special attention was also paid to the fact that the molecular mass of ethane is higher than that of methane and notably that of air. Wärtsilä carried out a complete Approval in Principle, which included special measures addressing safe gas monitoring and ventilation, with relevant classification societies.

The methane number (MN) of a gas indicates the gas´s resistance to self-detonation and subsequent knocking. Pure ethane has a methane number of 43, meaning that using the standard set-up would result in a maximum power output of 63% when using ethane. It was thus necessary to take actions to develop a low-methane-number-optimised combustion set-up that would enable Wärtsilä and Evergas to reach the target output of 73%, which would enable normal operation of the vessel.

To achieve the targeted output, simple but effective measures were taken to optimise the combustion set-up. The compression ratio of the engine was lowered slightly, and the boost pressure was also optimised for LEG through minor modifications to the turbocharger, by increasing turbocharger speed and boosting pressure at lower load. This enabled the requirements to be met with minimal changes to the engine configuration.

The automation system and software of the low-methane-number-optimised engine is unchanged compared to the standard set-up. The only modifications required to the engine control system are made via the user interface, in order to modify the maximum output in gas mode to 73% of the nominal maximum continuous rating.

During May and June 2015, a successful test and certification program was carried out. Upon successful validation, actions were taken to begin modifications to the delivered engines on the Evergas Dragon Series vessels to prepare them for operation on LEG fuel.

Fig. 5 - Optimal operating window of a lean-burn gas engine utilizing the Otto combustion cycle.

Table 1 - Gas properties of methane and ethane.

Fuel and gas handling systems

The Dragon vessel was originally designed to run on LNG, MDO and HFO, and the design criteria was to use LNG as fuel when trading ethane and other LPG cargoes. This was achieved by installing two, 1000-m3 fuel tanks, enabling the vessel to make a US-Europe return trip between every bunkering. Since the vessels also are fully-equipped LNG carriers, the cargo handling system and fuel system were already fully integrated by the team in Wärtsilä Gas Solutions. This integration allowed for an even better utilisation of the opportunity to use ethane as fuel.

When the test run of the engines was successfully completed, and Evergas ordered the conversion on the previously delivered engines, it was time to upgrade the fuel system to enable ethane. Given the quite similar properties between methane and ethane, there were only minor changes needed for the integrated fuel system, mainly because the engine could operate at similar parameters. The main work was in changing setting points on control valves of the system and a software change in the control system. Also important in this work was making sure that, after the modification, the system would also be able to switch seamlessly between the use of LNG and ethane as fuel.

Fig. 7 - Spot prices of fuels 2000–2015.

Summary of operating experience

The initial Evergas Dragon Series vessels were delivered in the summer of 2015. The first LEG cargo voyages, however, did not take place until March 2016, due to the fact that the LEG export terminal in Marcus Hook was under completion. During this period, the engines were converted from the LNG-optimised set-up to the LEG-optimised set-up and ran primarily on HFO. The maiden LEG cargo voyage departed from Marcus Hook to Rafnes, Norway on 9 March, 2016. Upon arrival in Rafnes, Wärtsilä supported Evergas in completing ethane gas trials on the Wärtsilä 50DF main engines. The world´s first ethane-powered marine voyage was carried out on 25 March, 2016 on the JS INEOS INTREPID.

In addition, to prove the fuel flexibility concept, JS INEOS INSIGHT carried out successful sea trials with LNG as well as LEG, confirming the quattro-fuel capability of the Wärtsilä 50DF-LEG engine.

As of 31 August, 2016, four ships were in operation in the Evergas Dragon Series fleet with an additional four vessels to be delivered within the coming months. All four vessels currently in operation have completed their ethane gas trials and are using LEG as their primary source of fuel. The main engines have accumulated over 11,500 hours operating on LEG with positive field experience reported.

Fig. 8 - Power consumption: re-liquefaction vs fuel mode.

Summary of customer benefits

Bunkering convenience & flexibility

The initial intention was that Evergas would transport LEG as cargo but burn LNG in the engines when running in gas mode. The ability to utilise LEG as a fuel in the engine thus eliminates the need to bunker separate liquid gases. The ability to burn ethane in the engines also enables Evergas to fill the deck tanks with LEG and empty them in Europe, leaving only enough LEG to complete the ballast voyage back to the USA. This effectively increases the payload and overall efficiency of the transport operation.

Fuel flexibility

Heavier gases, such as ethane, propane and butane, are commonly referred to as natural gas liquids (NGLs). Recent shale gas developments in the USA contain much higher concentration of NGLs than traditional gas sources, which has created a sharp increase in the production of NGLs in the USA.

The demand for NGLs in recent years, particularly ethane, has not developed at the same rate as production, creating a downward pressure on price. This resulted in an LEG spot price that makes it economically feasible – especially for an LEG vessel operator, who presumably has easy and cost-competitive access to wholesale LEG – to consider LEG as an alternative to LNG.

The excellent fuel flexibility (LFO, HFO, LNG, LEG) provides significant economic benefits and also limits the operator’s risk exposure to fluctuations in fuel price and spreads it over the entire lifecycle. It also enables multi-gas carriers to change easily between LNG and LEG charters without modifying the engines, giving better flexibility to the owner to change cargo charters.

Reduced Auxiliary Power Consumption

During the transport of LEG, some quantity of liquid gas will vaporise during the voyage and creates the need to re-cool the gas in order to re-liquefy it and send it back into the cargo tanks. The re-liquefaction process consumes a significant amount of energy.

When using a low-pressure, Wärtsilä dual-fuel engine capable of burning LEG, the operator has the opportunity to divert the vaporised LEG to the engine to be utilised as fuel. This significantly reduces, if not completely eliminates, the need to re-liquefy the cargo´s natural boil-off, thus providing a significant reduction in operating expenses both in the form of reduced auxiliary energy consumption and also reduced maintenance of the re-liquefaction plant, as shown in Figure 8.

An additional auxiliary benefit of Wärtsilä dual-fuel, Otto engines is that they require relatively low gas pressure, in the range of 2-5 bar, to operate. Alternative dual-fuel engines that operate on the gas diesel principle require gas pressures of approximately 300 bar for methane and even higher pressures of up to 600 bar for ethane.

Emissions

When used in a Wärtsilä dual-fuel engine, ethane, similar to LNG, has a very favourable impact on emissions, compared to liquid fuels in a traditional diesel engine.

The overall NOx emissions are reduced 80-85% when using either LNG or LEG compared to liquid fuels. The NOx emissions are summarised in Figure 9.

The Wärtsilä 50DF is certified as IMO Tier III compliant in gas mode, using either LNG or LEG, without the need for secondary exhaust gas treatment systems such as Selective Catalytic Reduction (SCR) and/or Exhaust Gas Recirculation (EGR).

Ethane does not contain sulphur so SOx emissions are all but eliminated when using LEG as a marine fuel, meaning that using LEG fuel is a viable means to comply with SECA SOx emissions regulations. Particulate emissions are also reduced by approximately 90% compared to HFO when using either LEG or LNG as an alternative fuel.

Gaseous fuels like LNG and LEG also produce approximately 25% less CO2 than liquid fuels when combusted, thanks to less carbon content in the fuel.

In general, it can be concluded that utilising ethane as a marine fuel has similar environmental benefits to LNG. Using LEG as a marine fuel enables Evergas to greatly minimise the environmental impact of their operation in comparison to traditional multi-gas carriers that normally have relied on HFO as their primary fuel.

The customer benefits were summarised by Steffen Jacobsen, CEO of Evergas, upon witnessing the successful LEG engine testing:

“We are very pleased that the Wärtsilä engines will be capable of utilising ethane boil-off gas as fuel. It increases our operational efficiency and improves flexibility in the bunkering of fuels. All in all, it results in a significant reduction in operating costs, while also providing a minimal environmental footprint. It also enables us to offer our customers increased flexibility, which has a monetary value to them."

Conclusions

The development of the Wärtsilä 50DF low-methane-number-optimised solution for the Evergas Dragon Series of LEG carriers has been successful.

The overall solution has several competitive advantages for LEG carriers, including the ability to utilise HFO, MDO, LNG and/or LEG with uninterrupted operation; IMO Tier III compliance without the need for secondary exhaust gas treatment; low gas pressure requirements and the ability to effectively utilise boil-off gas from the cargo. Sulphur emissions are eliminated using LEG, resulting in a highly cost-effective means for Evergas to be compliant in SECA zones in both North America and Europe. Particulate emissions are also eliminated, enabling smokeless operation.

The successful result of the project was enabled through strong collaboration between Wärtsilä, INEOS and Evergas. The project is a good example of how positive collaboration across the entire value chain can result in a winning solution and bring economic benefits to all parties and environmental benefits to everyone

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.