Ship owners and operators want reliable operations – and they also need to stay in budget. This is why many buy critical engine components from an original equipment manufacturer (OEM) and less critical, cheaper parts from a non-OEM supplier. But it may come as a surprise that even the less critical parts matter more than you think.

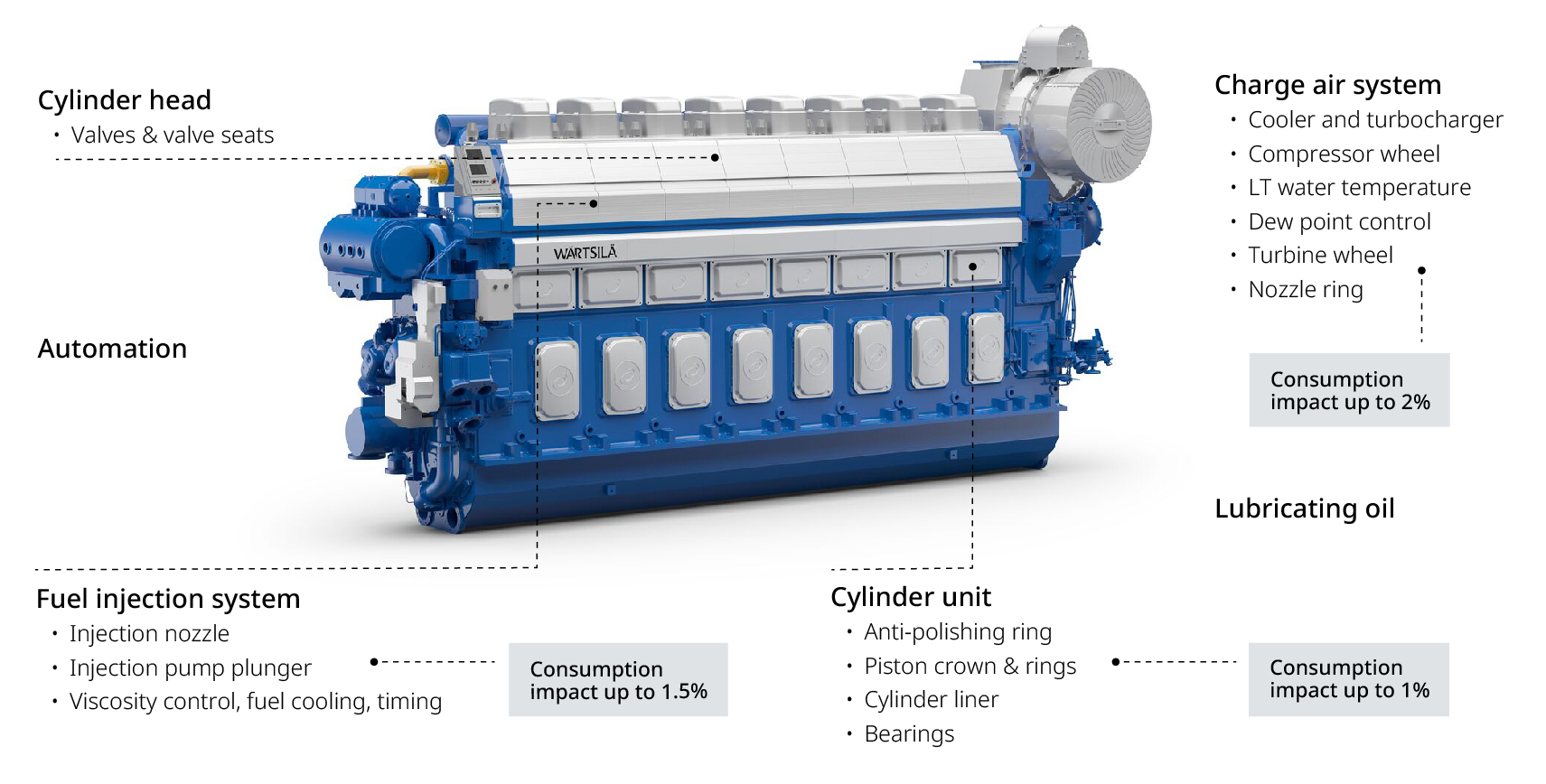

So, which critical engine parts do most buyers purchase from their original equipment manufacturer (OEM)? These components can be divided into four categories:

- Cylinder heads, including valves and valve seats

- Injection equipment such as nozzles and plungers

- Anti-polishing ring and piston-related components

- Parts for the charge air system including the cooler, turbocharger and air intake

It is a common mistake to think that if you take care of these critical spare parts you can protect yourself from problems. However, it may only take one failure of a single part – which you may consider less critical – for a major breakdown or malfunction to happen.

Here are three real-life examples of what could happen if you use less critical parts that have not been designed according to the correct specifications and tolerances to ensure proper fit and performance.

3 examples of small yet critical parts

1. Seals

Ships require a range of seals. They are used to stop water, dirt and dust from entering the engine, and to stop fluids like oil or other lubricants from leaking out into the environment. OEM and non-OEM seals might all look the same, but they can be different.

Fuel injector seals, for example, can differ from each other in the following ways:

- Shape: While OEM seals have circumferential uniformity, non-OEM seals may be unevenly cut.

- Materials: While OEM seals are made of high-quality materials according to the correct design specifications and tolerances, there is no guarantee of that when using non-OEM seals. There can be differences in material specifications.

While non-OEM seals may seem a cost-effective solution, they may not be manufactured according to the same manufacturing or quality assurance processes as OEM seals. The result could be a seal that wears prematurely or changes its flexibility and starts leaking fuel. This could lead to costly downtime and to loss of revenue, and you might have to shorten the maintenance intervals. Even worse, it could result in an engine fire.

Added together, the costs would far exceed the price of OEM seals.

2. O-rings

O-rings perform a similar function to seals. Just like seals, their design and materials are chosen according to the application they are intended for.

Genuine, high-quality O-rings are produced according to the OEM’s high standards and detailed specifications. This helps ensure they will perform as designed in your engine. Non-OEM O-rings may not be manufactured according to the same high standards.

A common mistake is to use an oil seal when you should be using a water seal – and vice versa. For example, installing an O-ring intended for lube oil in the engine room’s cooling water system could allow water to leak out.

The leaking water would slowly but surely cause corrosion, including on the cooling component surfaces. This can cause unplanned downtime and the need for more frequent maintenance – costing you money. You might also start to find more throw-away items instead of just O-rings that require replacement.

The root cause of this kind of problem may be difficult to identify until it’s too late because all O-rings look the same. They are almost always the same colour, and they are all the same shape. You might think that as long as an O-ring fits, it will perform as expected.

O-rings are manufactured according to different specifications, using thousands of different materials. This means that they have different tolerances and perform differently under different conditions.

Genuine, high-quality O-rings can save you money in the long run because they are produced according to the manufacturer's high standards to ensure they perform as designed in your engine. There is no guarantee of this when using non-OEM O-rings.

Handpicked related content:

To learn more about why using OEM parts is a good idea, download the white paper: "Why genuine spare parts are the best choice for your vessel – 5+1 great reasons".

3. Bolts and nuts

Most ships have thousands of fasteners such as bolts and nuts. These fasteners are used to hold almost everything on the ship together. Whenever you add new equipment to a ship or replace existing equipment these fasteners will probably need to be replaced too. While fasteners may all look like off-the-shelf parts, OEM fasteners adhere to a set of strict design specifications.

Bolts and nuts on ships are exposed to sea water, vibration and other harsh conditions for prolonged periods. This means they must be made of high quality, durable materials and designed specifically for marine environments. It is also critical to choose the right fastener for the right application.

If you buy a fastener that is not fit for purpose it could break or become loose. This could cause a leak, or even very expensive damage to your engine. For example, there have been cases where using the wrong fastener has led to damage to the rods connecting the engine pistons to the crankshaft. There have also been cases where loose or broken fasteners have led to valves falling into the engine cylinder and entering the turbocharger. This can damage the turbocharger, or in the worst case destroy the entire engine block.

It makes sense to use genuine fasteners from an OEM. They are made of high-quality materials according to the correct design specifications and tolerances to ensure proper fit and performance. They can hold and withstand vibration and weight better and for longer. In the worst case, non-OEM fasteners may last a matter of days before they break. This is why parts like fasteners may matter more than you think.

Using OEM fasteners not only saves you money, but also time. When you choose fasteners from an OEM you don’t need to spend valuable time searching for the right bolts and nuts because the OEM will be able to tell you which ones are fit for purpose.

How can you reduce risk even further?

Using high-quality spare parts that ensure proper fit and performance is not the only way to protect yourself from problems.

Many people may think that they can save more money by doing these simple maintenance tasks by themselves. But it is essential to know what you are doing. If parts are not installed correctly, the consequences can have a high price.

When you want reliable operations, tapping into the knowledge and expertise of the OEM can help you get ahead.

Handpicked related content:

To get practical tips for keeping your ship operating reliably while saving money, subscribe to this newsletter: "Expert tips for reliable ship operations".

Reducing risk with OEM less-critical parts

While choosing non-OEM parts may seem a cost-effective solution for less critical spare parts, using them can lead to:

- expensive repairs

- safety risks

- costly downtime, and

- revenue loss.

Added together, the total cost will be far more than the price of OEM spare parts.

For both critical and less critical spare parts, choosing genuine spare parts from an OEM is a smart investment in the long-term success of your operations.

Still not sure if genuine spare parts are right for you? Learn the truth about the most common misconceptions to avoid when buying spare parts – read this article:

7 truths about OEM spare parts you wish you had known before

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.