Wärtsilä’s recently signed contract in the Caribbean showcases the company’s capabilities in combining flexible power generation assets with energy storage for grid management – precisely the combination needed in today’s electricity markets.

Assuring electricity supplies on a small tropical island is all about using imported fuel wisely and having contingency plans in place for when something goes wrong, which it often does given the annual parade of hurricanes; or with other less predictable human events like a household adding intermittent PV solar rooftop generation or a vehicle hitting a pole and causing a short circuit event in the grid. It can be a tricky balancing act between cost and reliability.

St. Thomas, in the U.S. Virgin Islands, is about to get a more fuel-efficient, flexible and reliable power supply, thanks to a contract signed in June 2020 between its utility, Virgin Islands Water and Power Authority (VIWAPA), and Wärtsilä.

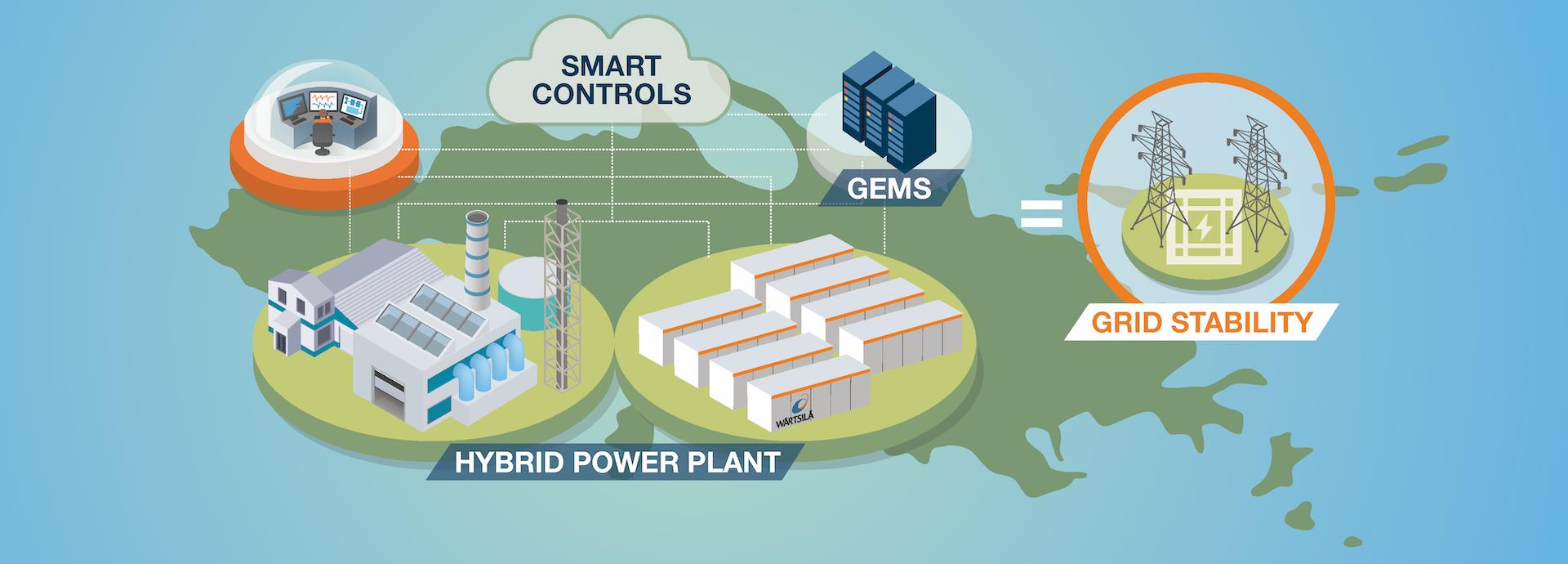

Wärtsilä is to provide a smart control system – its GEMS energy management platform – to optimise the entire island’s electricity generation, along with a hybrid plant comprised of a multi-fuel 36 MW engine power plant and a 9 MW/18 MWh energy storage system (ESS). This new hybrid plant will be located at the existing Randolph Harley Power Plant.

In addition to being Wärtsilä’s first engine/hybrid power plant sale, this will also be the first installation utilising the Wärtsilä 32LG engine – a flexible, multi-fuel engine capable of operating with hydrocarbons in the range from propane to LFO, or carbon number C3 to C20 – a landmark in the company’s development of engine solutions.

The hybrid plant will be delivered via an Engineering, Procurement and Construction (EPC) contract.

The project dovetails neatly with Wärtsilä’s energy vision, which envisages the need for more flexible capacity, with energy storage, in adapting to a renewable energy future.

Flexibility supporting reliability

The engines, energy storage and control system package for VIWAPA will improve the reliability of the energy supply, a challenge encountered in recent years. The utility has various generation assets on the island, including some ageing gas turbines, as well as newly installed engines running on propane fuel that Wärtsilä commissioned two years ago. Not only did VIWAPA need more capacity to meet its peak demand, but it also needed a flexible solution to kick in and provide electricity when older generation assets were unavailable.

Moreover, as all fuel to the island is imported, the existing system needed to operate as efficiently as possible in order to reduce fuel costs and, as a result, the cost of electricity. The utility did not want to be reliant on a single fuel and required that the new power plant be capable of switching seamlessly between diesel and liquid propane gas (LPG) – a less polluting option. This multi-fuel capability will help the utility hedge fuel price volatility in the future.

To make the most of the island’s fuel storage capacities, the multi-fuel engines were specified to give the utility more flexibility and ultimately reduce the chances of being affected by shortages in either fuel type. VIWAPA wanted the fuel changeover to be seamless, a feature not often available from competing technologies.

Energy storage system

As well as ensuring that generation capacity is increased, Wärtsilä is also supplying an energy storage solution and energy management system in the form of GEMS software controls and the GridSolv Max solution plus inverters, which will provide 9 MW of essential spinning reserve, frequency response and black-start capabilities.

Spinning reserves are on standby at all times, ready to provide extra power for a surge in demand or in case a generation asset unexpectedly goes offline. Using power generation assets for this purpose is costly, because idling engines burn fuel. Instead, the ESS will provide this service, freeing up the engines to run in their most efficient mode when producing electricity. The addition of energy storage will reduce fuel and maintenance costs for the utility.

The ESS also serves as spare capacity in case of an event on the grid – for example, if a hurricane strikes and takes out transmission or distribution infrastructure, or an engine generating set becomes unavailable for short periods of time. It is not designed to replace generation assets, but to provide the vital two-hour window for the utility to bring other generators online.

The ESS also offers grid forming and ‘black-start’ capabilities, critical for vulnerable regions like the island of St.Thomas, where aging generators used to restart a plant may become unavailable over time. To prevent blackouts across the island, GEMS can provide a response as fast as in 50 milliseconds. If a contingency event becomes unavoidable and causes a loss of connection between generators and the loads, the ESS black-start function allows the inverter to generate a sine wave for itself allowing, for instance, Wärtsilä 32LG engine generating sets to start and reach full power inside two minutes, quickly taking over the load initially supplied by the ESS.

The energy storage system is also an asset that provides voltage and frequency regulation. With an energy storage system on the grid, excess or insufficient power is absorbed or supplied to provide a ‘smoother’ electricity supply and preserve grid infrastructure.

All these features will effectively increase the service quality experienced by the customers of the utility.

Optimal dispatching

Impressive as these individual components are, the real star of the show is the GEMS Power Plant Controller, a product of the Wärtsilä GEMS platform suite. GEMS is an intelligent energy asset management system that will not only provide a single interface to control the operation of the new multi-fuel engines and the energy storage system, but will also integrate and synchronise all the other power generation assets on the St. Thomas island grid and ‘optimise’ dispatching – in other words, the system will carry out full grid management.

Wärtsilä’s GEMS conducts this synchronisation in the most efficient way possible by matching the electricity load with generation, so that supply equals demand at all times. For example, characteristics and parameters such as how long a power plant takes to start, what the optimal running conditions of the plant are, and what its fuel consumption is under given conditions are entered into the GEMS Fleet Director. Once all the data is collected, the control system considers fuel costs, battery degradation and the multiple engines’ efficiencies to meet the demand across the island, according to the GEMS economic dispatch algorithm, which constantly optimises the plant operation to deliver the lowest cost of electricity.

GEMS makes optimal decisions in real-time to maximise efficiency and minimise cost. Each calculation performed by GEMS adds to its bank of knowledge andis used to perform the next calculation, making it progressively smarter.

In addition to processing the data from the actual conditions experienced upon the island grid, GEMS incorporates load and weather forecasting alongside artificial intelligence machine learning. The combination of real and forecast data is thus progressively honed to produce increasingly optimal results.

GEMS, a fully-automated machine learning control system, offers a new tool for operators that will help them ensure that all critical assets in a power system are kept running at optimal performance for maximum benefit via onsite and remote operations with controls that can be set manually if needed from a single user-friendly interface. GEMS will maintain the health of the batteries, as well as provide grid control functions, and monitor, control and optimise the plant operation, along with aggregating all plant data for maintenance support and root cause analysis when necessary

Wärtsilä’s GEMS Power Plant Controller also conforms to the highest cybersecurity standard, IEC 62443, ensuring best practices in communication and access security. With GEMS cybersecurity, all network traffic can be monitored for incident investigation and restrictions can be defined to allow secure access, while ensuring the safety protection of the hybrid plant operations.

Future-proof cornerstone

The power plant is expected to move into full operation in spring 2022, with the integration of all the island’s generation assets into the Wärtsilä GEMS control system carried out from then onwards. From the moment the new hybrid plant comes online, VIWAPA and its customers will benefit from reduced operation costs and improved reliability and service quality.

“The Wärtsilä engine generating units will be critical to the Virgin Islands Water and Power Authority’s ability to maximize the full potential of its recent conversion from fuel oil to LPG as the primary fuel source. The Wärtsilä power plant will be a cornerstone in providing not only reliable and highly efficient power generation, but in making more affordable electricity available to our customers,” said Lawrence Kupfer, WAPA Executive Director and CEO.

The beauty of this story is that it doesn’t end there. The Virgin Islands, as elsewhere in the Caribbean, have a huge potential for increasing their renewable wind and solar capacity. The combination of flexible generation, energy storage and intelligent asset management means the infrastructure is in place for the islands take more steps on a renewable, resilient, and reliable energy path.