Waterjets have many exciting applications from navy vessels to big, fast ferries, as Wärtsilä has been able to find a great balance of light weight waterjets, which have strong durability with large engine power. Now LNG-fuelled ferries offer a possibility to open new markets, where both Wärtsilä engines and waterjets can be installed to the same vessel.

18th Century Swizz mathematician and physicist Daniel Bernoulli is not someone that many outside the world of mathematics recognise. However, his name might ring a bell for people inside the marine industry. In 1753, Bernoulli investigated and proved the theory behind waterjet propulsion as part of his hydrodynamics research in physics. His theory was applied to practice and vessels that used the power of waterjets were soon sailing at a speed of 9 knots.

Flashforward to our time and Wärtsilä waterjets are powering high-speed ferries and navy vessels, which might sail at speeds averaging 40 knots. An impressive example is the catamaran Francisco, the fastest ferry in the world which ferries passengers between Uruguay and Argentina at a speed of 53 knots.

Wärtsilä waterjets are a result of persistent innovation and development work. Wärtsilä has an in-house development and sales unit for its waterjet range, located in the Netherlands, and Sales manager Jeroen Vedder has been working for the waterjet unit for the last three years.

Waterjets were added to the Wärtsilä portfolio in 2002, when Wärtsilä acquired the Dutch company Lips, which was a global leader in propulsion products, including waterjets. Lips Jets eventually became Wärtsilä Jets.

“The history of waterjets is long, but I would start the story a lot later, perhaps from 1976. That was the first time Lips waterjets were delivered for engines with a power of 495 kW,” says Vedder.

Smaller, lighter and faster

In 2006 Wärtsilä introduced its compact LJX modular waterjet series. In the name, L represents the roots of the innovation, as it means Lips. J stands for Jets and X for the innovation of an axial pump, instead of a mixed flow pump. The new waterjet was 25% smaller in flange diameter, and therefore its weight was reduced by 10%. The cavitation margin was also reduced by 35%. The LJX-waterjet range formed a solid base, which future designs could lean on.

“That was probably the biggest milestone until now,” says Vedder. “We had executed a big change in the overall design of the waterjet.”

Another breakthrough was the introduction of the midsize waterjet series in 2011. The midsize series of Wärtsilä waterjets are designed for engines with power ranging from 500 kW up to 4500 kW. Compared to the modular waterjets, the midsize waterjets are preassembled on a skid and delivered in form, which allows direct installation into the vessel hull during the construction at the shipyard. All components of the waterjet are mounted on the skid, including outboard parts, the PTO, thrust bearing, hydraulics, and machinery controls. The skid is formed around the waterjet inlet. This means the inlet is also part of the scope.

“This is a different concept, compared to the modular waterjet, where the inlet design is done by Wärtsilä. The production of the inlet itself is part of the yard scope,” says Vedder. “Another big difference is, that while modular waterjets are fully executed in duplex stainless steel, the midsize has many aluminium parts instead of duplex stainless steel.”

The way in which the modular and midsize series are delivered to customers is also quite different.

“In the modular type of waterjet, we can do more variations and optimisations, depending on the vessel type. The strength of the midsize is the shorter delivery time and the

use of aluminium components built together on a skid,” says Vedder. “The modular waterjet, on the other hand, offer a high level of customisation with a wide variety of options available depending on the vessel type. But there are a two

things that both types have in common; high-quality and a well-proven performance with an identical axial pump design.”

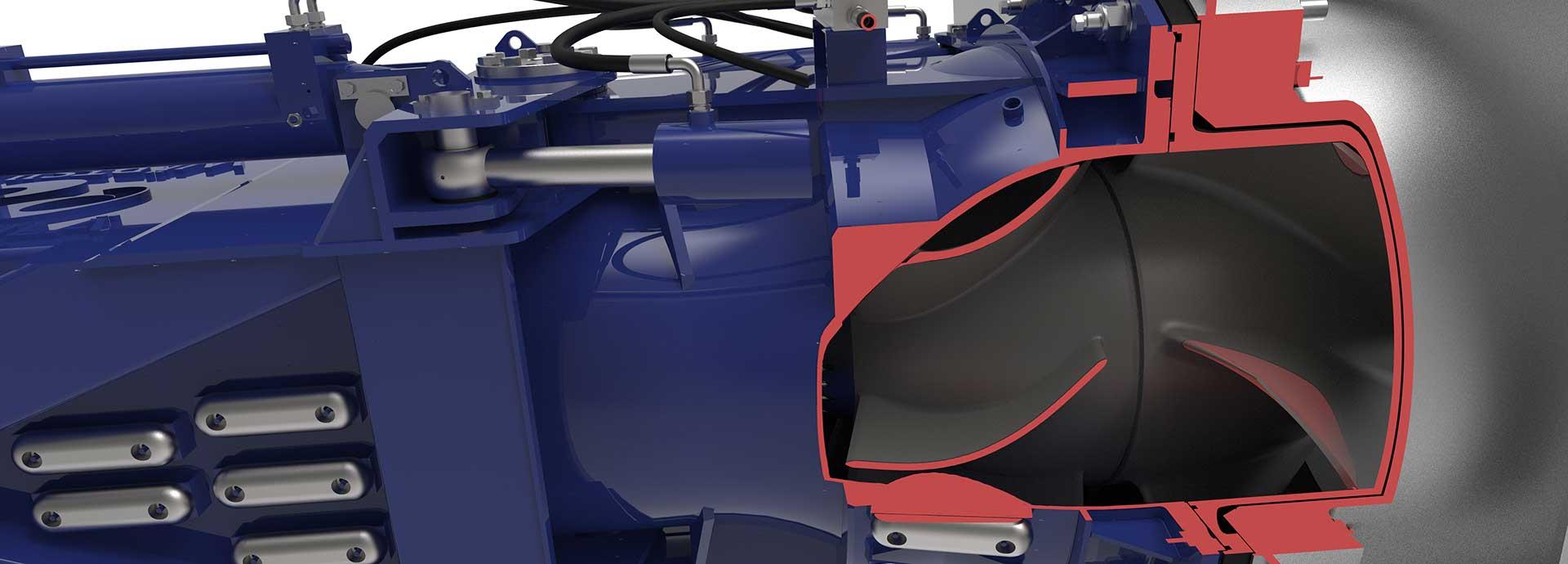

Wärtsilä WXJ modular waterjet

Exceptional engineering

Vedder is now looking forward to working with a redesign of Wärtsilä’s modular waterjets, revealed in January. The last time the modular waterjet design experienced a revolution was in 2006 when Wärtsilä introduced the LJX-range of waterjets. Now the LJX-series will evolve and be introduced as WXJ-series.

The new Modular waterjet series will feature a new axial pump design, which boosts performance with an increased thrust of as much as 3%, while the improved cavitation margins will help reduce the environmental impact by lowering noise levels. This is very much in line with Wärtsilä’s Smart Marine vision that aims to lead the maritime industry into a new era of ultra-high efficiency, improved safety, and reduced environmental impact.

The new WXJ pump has been tested extensively, both with computational fluid dynamic (CFD) simulation and with model testing. With this successful upgrade, Wärtsilä is now in a position to deliver waterjets worldwide, including to promising markets like China and the other Asian countries.

The axial pump structure is already a factor that sets Wärtsilä apart from its competitors in the waterjet market. Compared to the mixed flow structure, the axial pump means much less space is needed on the vessel’s transom, as well as increased cavitation margins for better operational flexibility. Furthermore, there is a significant weight difference in favour of the axial pump compared to the mixed-flow pump.

Vedder also says that another advantage that Wärtsilä waterjets have compared to other products in the market, is the fact that they have an inboard mounted thrust bearing. Because the thrust bearing is not within the water flow inside the jet, there is never a risk for oil leakage in the water.

“Usually the equipment that makes the jets steer and reverse is located outside the vessel, and is being exposed to seawater,”

he explains. “This means that the maintenance and repair can be difficult to do at times. But we have an option to install the hydraulics, such as the cylinders and hoses, inside the vessel, which also allows early and easy detection of possible

oil leakage.”

Baleària’s new high-speed catamaran will be the largest such vessel to operate on LNG. It will feature an integrated scope of Wärtsilä solutions.

The complete package

In spite of these advantages, Waterjets have, so far, not been an obvious addition to Wärtsilä’s broad portfolio of marine technology solutions.

“If you look at products within Wärtsilä, waterjets could even be considered to be side-tracked by the other products, and have not had a strong connection to the rest of our portfolio,” explains Vedder. “Waterjets are commonly used in combination with high-speed engines and until the end of 2018, Wärtsilä has only had medium-sized engines. So there have not been many possibilities to offer a complete package before. This is why I am very happy about the introduction of the Wärtsilä 14 high-speed engine.”

Over the past decade, due to economic reasons and tightened environmental requirements, the fast ferry market has been faced with similar pressures as the marine industry in general. Vessel operators want to reduce operating costs while being efficient and environmentally sustainable at the same time. As a result, the fast vessel market is looking towards a new era of LNG-fuelled vessels, which in turn mean exciting new possibilities for Wärtsilä waterjets as well.

In fact, the first new vessel equipped with Wärtsilä waterjets, LNG solutions, and Wärtsilä engines has already been commissioned by Spanish Ferry operator Baleària, which plans to build the largest ever high-speed catamaran, which will operate on LNG fuel. The 125-meter-long vessel will be the first high-speed ferry that will feature both Wärtsilä waterjets and the Wärtsilä 31 DF medium-speed engines along with an LNG fuel storage and supply system.

Meanwhile, Vedder is looking forward to the possibilities of offering customers an even broader package from Wärtsilä.

“LNG as a solution for fast ferries was not an option that everyone believed in, as weight in the fast ferry business is an essential thing. Electric marine technology will, for sure, be the future. However, I still think LNG will serve as an in-between solution before marine electric technology becomes more suitable,” he says.

Vedder and the whole Wärtsilä waterjet team are already looking ahead and have their sights on serving the high-speed vessel market, which is increasingly looking for lighter solutions to save fuel consumption and thereby, the environment.

“Sailing with fast vessels is a bit like Formula 1 racing. The lighter you are, the better the performance. Therefore, we are always looking into other solutions to save weight and to improve the performance even more. There are several projects ongoing, but it is obvious we can’t say much about it yet. We don’t want to help our competitors by giving them our good ideas!” he explains.

“We are looking at all parts on the waterjet to see if we can find something to improve the performance even more without compromising the reliability and durability. The team has listed some revolutionary ideas and I look forward to working on them this year,” concludes Vedder.