With the newly upgraded version of Operim, released at the Nor-Shipping trade fair in Oslo in June 2019, Wärtsilä shows that it is serious about anchoring itself in the domain of intelligent engineering.

The Operim system was first launched in 2011 to monitor the performance of Wärtsilä’s LNG cargo and reliquefaction plants on ships. Operim, short for Operational Performance Improvement & Monitoring, lives up to its tagline: “Forget about optimisation – with Operim, it’s always on.”

Originally designed to monitor and optimise onboard gas plant performance with simple calculations and manual data sampling, the early Operim system, designed by Wärtsilä Gas Solutions, aimed to help crews optimally operate large reliquefaction plants, reduce their 6 MW power consumption and keep the associated environmental footprint to a minimum. The cargo handling system, with a reliquefaction plant at its core, plays a significant role in the efficient operation of gas cargo tankers.

On a typical voyage from Qatar to Japan, for example, up to six tonnes of cargo per hour are managed by the reliquefaction process. Without careful operation and consideration of the varying operating conditions throughout the voyage via Operim, efficient operation would be compromised. With ever-increasing financial pressures on ship owners and operators, the need for operational efficiency is higher than ever before, which is why Operim has been updated to utilise the latest technology to support our customers and help them meet their business challenges.

Fleet performance dashboard: KPI trend indicator.

So what’s new with Operim?

Thanks to the increased availability of rich and near real-time data and upgrades to web and software interfaces, the application areas of Operim have widened beyond just LPG and LNG reliquefaction plants. Recent upgrades include land-based biogas, fuel gas supply systems and waste and water treatment solutions. Other processing assets will follow. Based on the widespread application areas of Operim, Wärtsilä has enhanced its Smart Marine Ecosystem strategy and is quickly developing new business models to support it.

For owners and operators, Operim enables a slew of cost-saving operating performance improvements in a continuous and dynamic fashion. Vessels are only as efficient as the way they are operated, and with Operim, inefficiencies and profitability impairments of all types can be identified and rectified to reach optimal operational efficiencies. Operim can, in a nutshell, constantly provide advice and insights on how to adjust working parameters in accordance with sea and weather changes as well as monitor maintenance routines and early warnings.

Used properly, Operim can also make money for users via cost savings. There are frequent developments in environmental compliance for individual ships and entire fleets that have to be managed. That’s just one of the many complex variables involved in running a fleet smoothly and efficiently while adjusting to different local conditions around the world. Operim helps synthesize all this data.

Additionally, as crews age and expertise and know-how are lost to attrition, newer crews need – and, in fact, require – data-rich environments in order to make accurate, fact-based decisions onboard ships.

Operim: Digitally enabling physical devices for smarter performance.

Digitally augmented and integrated with Operim

What really makes Operim a linchpin in Wärtsilä’s Smart Marine Ecosystem is how it will become packaged and included in the sale of new physical hardware. In the foreseeable future, all of Wärtsilä’s physical products could be digitally enabled this way as part of the brand promise. This is unique in the industry. It leverages Wärtsilä’s broad portfolio and product heritage and is not easily replicated by new digital entrants to the market.

Additionally, Operim can be retrofitted to existing installations and made available via a Service Agreement, either stand-alone or, typically, as part of a broader Wärtsilä agreement. Wärtsilä’s unique competitive advantage over pure software and data companies working only in the virtual space is that the company has in-house at its disposal the engineers who designed the machinery and can offer support in the form of a live chat functionality backed up by real-life expertise. This level of product understanding and support on a web interface is not just unique, it also strengthens the connection between the customer and Wärtsilä.

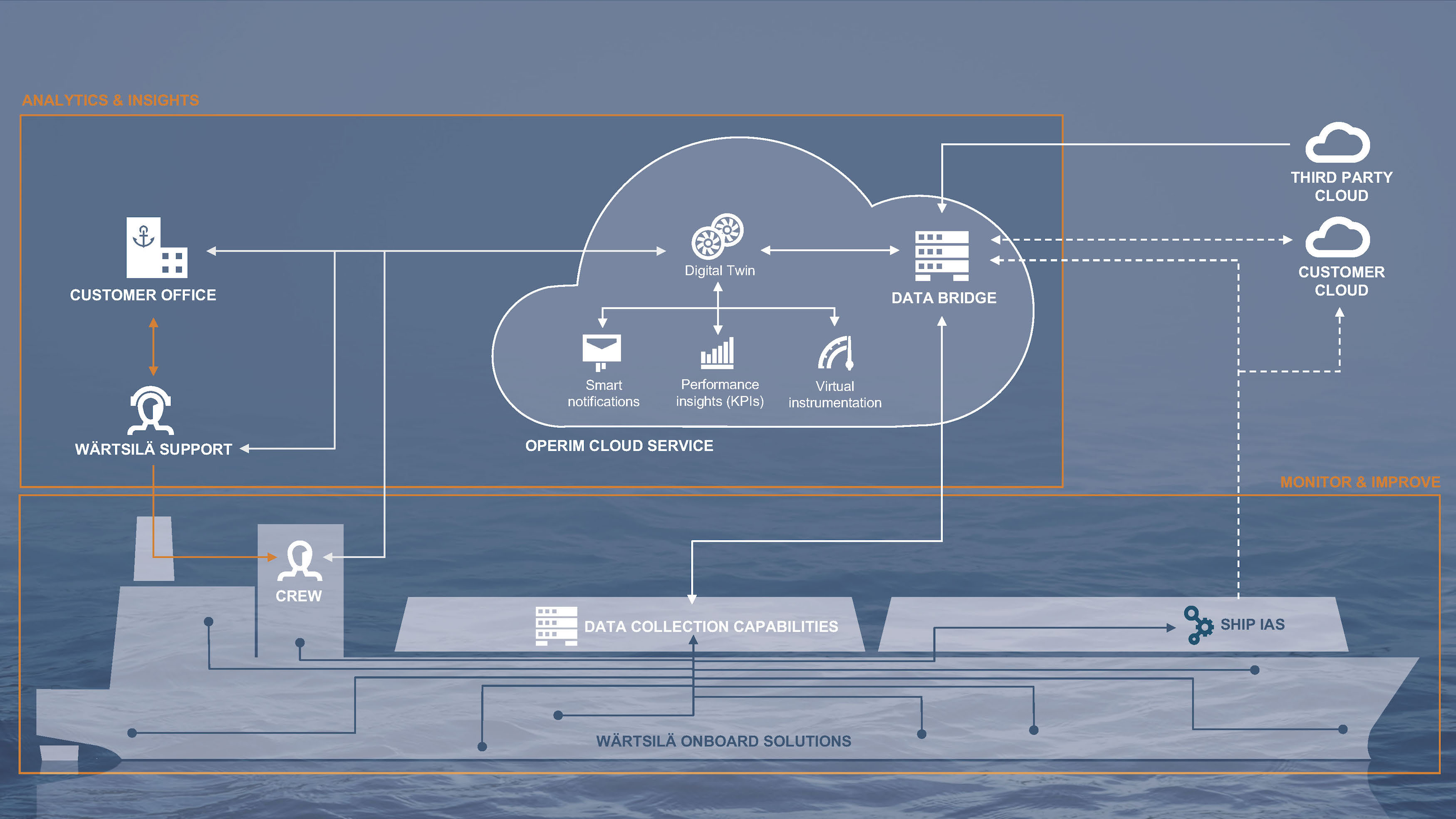

Digitally augmenting the product starts by enabling data collection. This can be achieved in several ways, depending on the configuration of the vessel and customer preference, by installing dedicated Wärtsilä hardware or using the vessel Integrated Automated System (IAS) system. Additionally, if the customer already has data in a cloud system, this also can be utilised. Once the data is collected, it enters the Operim cloud service, which features Wärtsilä’s digital twin of the product being monitored.

Voyage report and operation insights with Operim.

Analysing the process performance through Operim dashboards.

A digital twin

At the core of Operim is a digital ‘twin’, developed with the help of product engineers and data scientists. This twin allows the system to compare actual performance against optimal performance and ascertain areas for improvement.

These areas then can be visualised through dashboards in the form of KPIs and smart notifications for operators and crew members. They are accessible to the crew onboard the vessel as well as to the team onshore via a web-based dashboard hosted in the cloud, enabling the team members

to use analytics and insight to monitor and improve the product performance.

From a user perspective, the interface is reliable and easy to use. A ship operator can easily access his fleet dashboard in the Operim system, which provides a near real- time overview of the operational health of the company’s vessels, clearly outlined in red and green with average KPI indicators visible in a separate window.

Operim: insights dashboard.

Voyage reporting

One concrete example of Operim’s usability is the voyage report and operation insight window inside the system.

For example, think about a gas cargo ship travelling between the UK and the US in the cold waters of the North Atlantic. Considering the temperature of the ocean, Operim can alert the crew to the need

to pre-cool cargo such as liquefied gas when in cooler waters instead of waiting until the ship reaches warmer waters and using energy to cool the cargo then. This kind of precision was nearly impossible

in the past without a very experienced operator and could be based at best on a guesstimate of the ship’s position. Operim, however, can provide minute details about a vessel’s route and assist with planning adjustments depending on weather, current and water temperatures, to name just a few variables. The hope is that in the future, this functionality will lead to fuel savings based on different route positioning.

Future features will incorporate the automation of recommendations and utilise machine learning to complement the digital twin, providing richer insights. Operim also will be enabled to interact with other Wärtsilä systems, such as Wärtsilä Online, Expert Insights, and voyage planning solutions, allowing asset-specific optimisation to be considered in voyage planning.

Operim is central to Wärtsilä’s Smart Marine Ecosystem approach to creating greater levels of efficiency, safety and environmental sustainability as the maritime industry adjusts to meet the challenges of an emerging new era.

Operim leaderboards: learn how efficient the operation is across the fleet (KPIs).

Operim leaderboards: learn how the power consumption is across the fleet.