It has been a stellar year for Wärtsilä’s shaft generator business. These clever systems, which have been around for more than 50 years, generate power for a ship’s auxiliary systems from its main engines. Today, they are also being used to reduce emissions.

As of last month, more than 500 shaft generators have been installed on ships worldwide, reaping major operational benefits for owners and operators. Today, shaft generators don’t just lower operational costs. With emissions controls increasingly under the microscope, it turns out that a hybrid system made of a shaft generator coupled with large electric batteries is an economical and environmentally friendly means of generating both electrical and propulsion power while in port.

“This is a success I would say – on two fronts,” says Michael Kranz, Manager, Shaft Generator Systems & Cargo, who oversees a department of eight engineers at Wärtsilä’s Marine Electrical Systems. “Last week, we reached 500 units sold, an incredible milestone. In the same week, we sold a comprehensive (holistic) hybrid system to a series of hybrid RoRo vessels. After a relatively slow start to the year, we are now seeing a big increase in these systems being specified by owners interested in reducing emissions and fuel costs.”

Bundles of savings

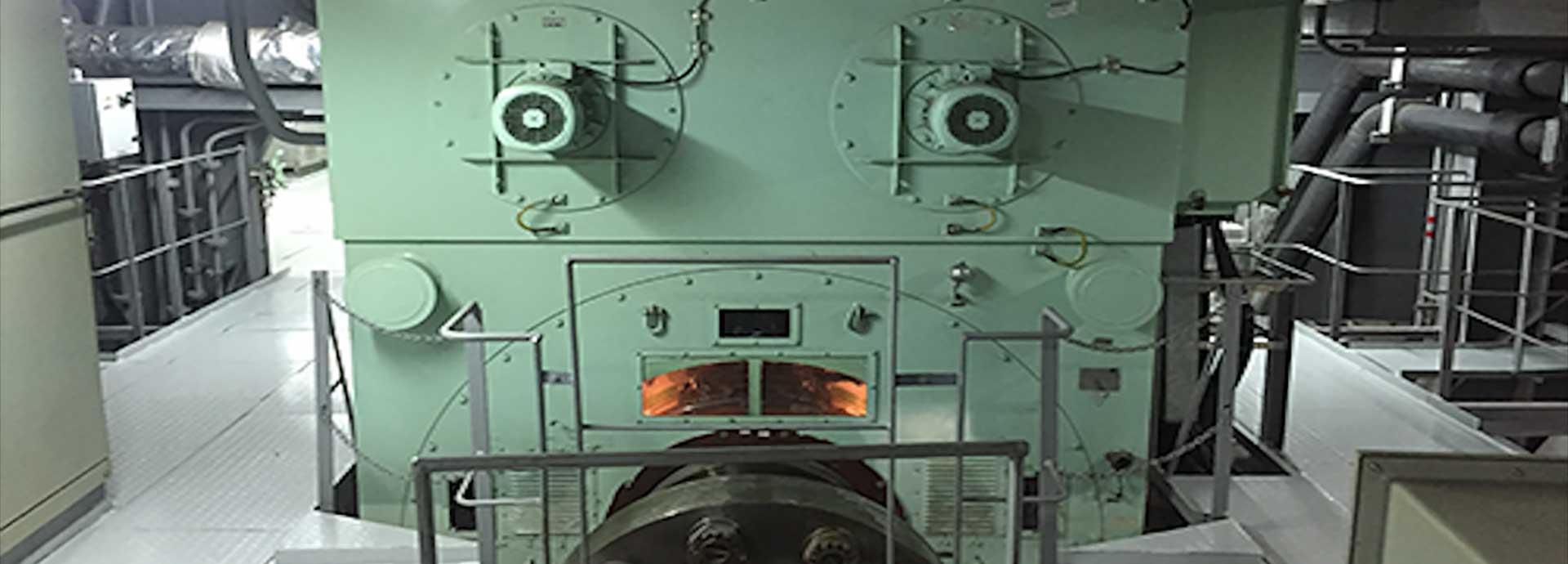

The main idea of a shaft generator is to piggyback on the main engine and propeller shaft’s rotational motion to generate electricity. Regardless of the engine speed, a frequency converter assures the supply of three-phase current at a constant voltage to operate electric machinery onboard, including propulsion engines and bow thrusters. The advantages are numerous and include a drastic lowering of fuel costs. The main engine’s drive shaft generators are operated with heavy fuel oil, often in combination with Wartsila SCR’s (Selective Catalytic Reduction), instead of the more expensive marine diesel oil used on generator sets. As well as a reduction in maintenance and lubrication costs on the diesel generator sets, the system is also quieter and safer.

Shaft generators have been installed on a wide array of ships, including container vessels, cargo vessels, bulk carriers, LNG and LEG carriers and RoRo ships. With the installation, shipping operators save a bundle by not having to use separate auxiliary generators that run on more expensive diesel oil, according to Luciano Crapanzano, Superintendent - Technical Department at Atlantic Container Line. The company commissioned five new container ships in 2015 and 2016 with shaft generator systems.

“The Wärtsilä shaft generator systems onboard the Atlantic Star series of container ships is definitely an advantage in terms of fuel savings,” Crapanzano says. “Indeed, considering the SFOC [g/kWh] difference between the shaft generators and the auxiliary engines, we expect to save around 1,2-1,5 mt/day at the vessel service speed. Furthermore, by reducing the auxiliary engine use, maintenance costs are also positively affected.

German ship operator Hartmann Reederei has also incorporated Wärtsilä shaft generators into their carriers. The JS INEOS MARLIN, a newly built 85K VLEC and the biggest ethane gas carrier in the world features a Wärtsilä shaft generator system, as do the GASCHEM BELUGA, the GASCHEM ORCA and the GASCHEM NARWHAL.

“The Wärtsilä Shaft Generator System has clearly more than fulfilled our expectations,” says Ionut Cornea, Head of Newbuilding Department at Hartman Reederei. “After a successful sea trial and taking our LEG Carrier into service, the Wärtsilä Shaft Generator System is running remarkably reliably. It enables us to cool down our valuable cargo with the best efficiency and thus with the lowest costs we have ever experienced. We clearly recommend the selection of this type of system for future projects as we are completely convinced of the design of the Wärtsilä Shaft Generator System.”

Cornea adds that Wärtsilä technical support also has contributed to making the collaboration a success.

“We’ve faced a few challenges with the shaft generators, but due to the Wärtsilä team’s 24/7 availability, we’ve been able to minimise offline time to just a few hours,” Cornea says.

Achieving shipping’s ‘holy grail’

Shaft generator systems are a recognized valuable technical solution for shipowners looking for economical and cleaner electrical power generation. What’s really new in the shaft generator system world, however, is how these systems can be used with hybrid battery systems and energy management systems in providing zero emissions to operational ships while still in port.

This is the holy grail of emissions-free shipping, and a keystone in Wärtsilä’s Smart Marine Ecosystem way of thinking, because the public at large still associates shipping with belching smokestacks.

“Together with our Smart Energy Management System, ships in the harbour can now operate on battery storage alone and react within milliseconds without the use of auxiliary and redundant engines for safety. This Uninterrupted Power Supply, or UPS, is a key feature of our EMS system and the shaft generator system is what makes it all possible,” concludes Kranz.