Sustainable marine fuels like methanol and ammonia are quickly becoming a must-have for fleet managers as emissions regulations become stricter. But the transition to these fuels requires new skills and ways of working from your vessel crew and onshore staff – and it can feel overwhelming.

Here are the five biggest challenges you can face when onboarding your vessel crew and onshore staff to sustainable fuels:

- Crews are not familiar with the latest fuel systems

- Crews are not familiar with how to handle sustainable fuels

- There are more things to maintain

- Your assets might not be performing optimally

- Costs are difficult to predict and budget for

Challenge 1: Crews are not familiar with the latest fuel systems

The internal combustion engine (ICE) technology needed to use sustainable fuels like methanol and ammonia is not new in itself; it has just been adapted to use these fuels. What is new is the fuel technology that modern multi-fuel engines are equipped with. The fuel systems of modern multi-fuel engines are more complex, containing elements that do not exist in conventional engines. In these engines, elements such as the valve timing, turbocharger technology and engine automation also have a role to play in ensuring that the engine meets the highest standards of efficiency and produces lower emissions.

All this can feel overwhelming. Most crews will have little or no experience with the latest fuel systems. Transitioning to these new systems requires new skills and ways of working.

How to solve the challenge

The most capable OEMs can offer practical training for vessel crew and onshore staff that can be fully tailored according to your needs.

The training could also be part of a service agreement with your OEM, which can also serve as a training and onboarding programme for your crew. This way your crew can learn from top experts over time about how to solve the problems that occur most often – and get expert support whenever they need.

Training could also be arranged on your own ship by certified OEM experts who know every part of your equipment. This type of training makes it easier for your crew to learn new things and new ways of working as the environment is already familiar to them. Onboard training also means your crew don’t need to travel anywhere. Alternatively, if you oversee and manage a fleet of vessels, simulation training using new technologies like AR and VR might be a more cost-efficient option.

A skills/knowledge assessment survey or questionnaire is a great way to identify development needs. The questions can be used to map out what crews know and what they should learn more about. The survey could even take the form of an exam or test.

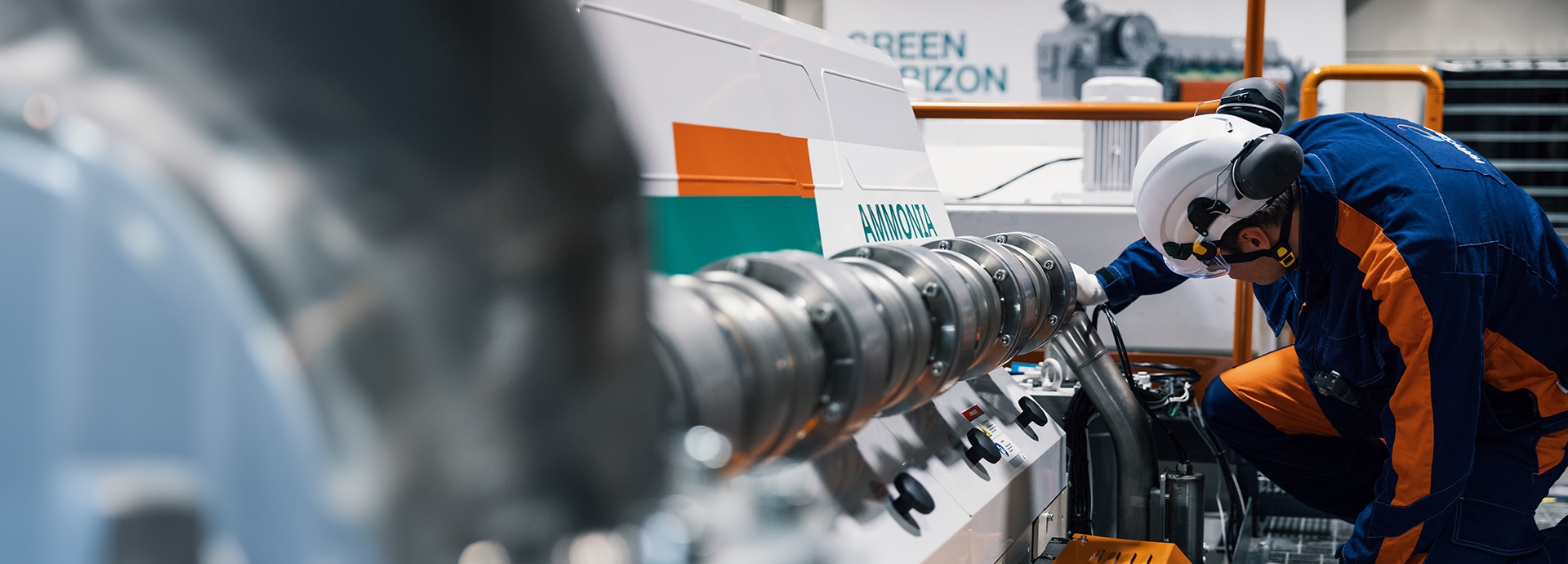

Challenge 2: Crews are not familiar with how to handle sustainable fuels

While sustainable fuels such as methanol and ammonia are safe to use when the right precautions are taken, they require strict adherence to proper handling, storage and usage practices.

This is because methanol and ammonia are both toxic if they come into contact with skin. Ammonia, which is a colourless gas, is also toxic if inhaled. Because methanol is a liquid, the risk of inhaling it is smaller. However, methanol is flammable, and you may not even see the fire because the flame is invisible. For these reasons you must have appropriate safety measures in place and strictly adhere to proper handling and storage procedures. A vessel that uses ammonia or methanol as fuel will need to have:

- appropriate personal protective equipment (PPE) for the crew

- ventilation systems and gas detection systems specifically designed for ammonia or methanol

- proper fire suppression systems, and

- established safety protocols.

All this can put extra strain on your crew because they may not be familiar with the new fuel and the best way to handle it safely.

How to solve the challenge

Because methanol and ammonia are both toxic, you should ensure that all your crew members know how to safely handle whichever fuel you are using. Crew members must also be fully aware of the emergency response procedures that must be followed in case of fuel leaks or other incidents.

The most experienced OEMs will be able to offer thorough – and if necessary tailored – training on the proper operation, maintenance and safety procedures for modern multi-fuel engines and fuel handling systems. This training can be included in a service agreement. By implementing these measures you can reduce the risk of accidents and significantly improve safety when working with methanol or ammonia as fuel. If you manage a fleet of vessels, simulation training using technologies like augmented reality (AR) and virtual reality (VR) can be a cost-efficient way to upskill your crews.

Some OEMs can also deliver complete systems for handling these new fuels in a safe way, from storage and bunkering to control and monitoring.

Handpicked related content:

Have you explored the fascinating world of VR training yet? This article reveals a host of surprising benefits you could gain from this effective training method: 10 intriguing pictures that show the magic and the benefits of VR training.

Besides training and special fuel handling systems, predictive maintenance services are another way to help ensure a safe working environment for your crews. Predictive maintenance services continuously analyse incoming data from sensors onboard a vessel and can detect anomalies early on. This type of service can also give you peace of mind because you know you’ll get an early warning that helps you resolve problems before they become major issues.

Having operational support available around the clock can also give you peace of mind because you know that you’ll get help and advice whenever you need it. A dedicated expert in your OEMs remote support team can give actionable advice and help resolve your issues no matter when or where they occur.

Challenge 3: There are more things to maintain

Just as with conventional engines, keeping modern multi-fuel engines in top condition requires regular maintenance. However, a new fuel with its associated fuel supply system often comes as an addition to the conventional fuel infrastructure, meaning there are more elements to maintain. This is because there is one system for the pilot fuel and another for the main fuel.

Managing and maintaining these new systems and technologies can put extra strain on your vessel crews and onshore staff. You may need to hire new people to cover the extra workload, and they might not be familiar with these new systems and fuels. A lack of personnel with the required competencies can make it harder to keep your equipment in top condition.

If ways of working are not adjusted to meet the requirements of a new fuel it can lead to:

- higher fuel consumption

- reduced efficiency

- higher operational costs

- increased emissions

- safety hazards

- costly repairs and downtime, and

- non-compliance with environmental regulations.

How to solve the challenge

With an OEM like Wärtsilä as your expert partner you can ensure that your equipment is in top condition and maintained regularly. This ensures that equipment performs reliably and optimally throughout its lifecycle – even if you don’t have enough staff with the right competencies.

In addition to regular maintenance, a dedicated expert in your OEM’s remote support team can act like a member of your extended crew, giving actionable advice and helping you resolve issues no matter when and where they occur.

You can also make life easier and less stressful with predictive maintenance services. These services continuously analyse data from sensors onboard your vessel, providing early warning of minor problems so you can resolve them before they become major issues.

A service agreement with your OEM can also serve as a great training and onboarding programme for your crew. Over time, your crew will learn how to maintain the equipment and solve the most common problems while getting support from an expert whenever they need it.

Handpicked related content:

What simple maintenance trick can transform your emissions reduction strategy and deliver greater wins for your fleet? This article reveals one awesome game changer:

Transform your emissions reduction strategy with one awesome, simple trick

Challenge 4. Your assets might not be performing optimally

New regulations like the EU’s Fit for 55 package, which aims to achieve a 55% reduction in greenhouse gas emissions from 1990 levels by 2030, will have a significant impact on the maritime industry.

Shipping companies who have either already adopted or are in the process of adopting sustainable maritime fuels are thinking about how they can ensure that their assets perform (and continue to perform) at an optimal level so that they can comply with the stricter regulations.

New sustainable fuels may also not be available everywhere or may be more expensive at least in the short term. Because of the added costs, you may need to optimise your fuel usage by switching your main fuel from time to time. And every time you switch your main fuel, your engine must be optimised for that fuel if you want to maintain maximum fuel efficiency.

How to solve the challenge

A service agreement with your OEM can help keep your assets performing optimally in various ways. These include, for example:

- Regular maintenance and optimisation. Proper maintenance ensures that engines and equipment operate efficiently, reducing fuel consumption and emissions.

- Expert support. Experts can offer guidance on best practices for reducing emissions, implementing energy-efficient technologies and complying with regulations.

- Upgrades and retrofits. Upgrading or retrofitting your existing equipment with more efficient and environmentally friendly technologies will help to reduce emissions.

- Monitoring and reporting. Monitoring and reporting services allow you to track fuel consumption, emissions and compliance with regulations, so you can identify areas for improvement.

- Training. Proper training ensures that staff are knowledgeable about emission reduction techniques, fuel efficiency practices and regulatory requirements.

- Predictive maintenance. Proactive predictive maintenance helps maintain optimal performance and reduces the risk of unexpected failures that could lead to increased emissions.

- Proper fuel management. Proper fuel management – including fuel quality testing, fuel switching strategies and advice on using alternative fuels – helps reduce emissions and improve compliance.

- Compliance support. Help with navigating complex regulatory requirements and ensuring compliance with international and local environmental standards. This can include support with documentation, certification and audits.

With an outcome-based partnership, you could even get a guarantee that your targets will be reached and maintained – giving you even more peace of mind. Outcome-based service agreements align your interests as a customer with those of your service provider. Together you agree on what you want to achieve, then you work together towards those goals. Risks are shared and results are guaranteed. It’s a win-win solution.

Handpicked related content:

Are you targeting increased vessel uptime, fuel savings or lower emissions? What if a certain quantifiable outcome could be guaranteed? This white paper reveals a surprising way to achieve your goals:

How a service agreement could give your maritime business a competitive edge.

5. Costs are difficult to predict and budget for

Although sustainable fuels produce less emissions, they are currently more expensive than fossil fuel. In addition, their availability as marine fuels is still limited. Vessels that use sustainable fuels will also need more fuel and therefore more storage space onboard. This is primarily because of the lower energy density of sustainable fuels. In addition, maintenance costs can be higher because the fuel systems of modern multi-fuel engines have more elements to maintain. These additional costs, as well as the costs related to CO2 emissions, are difficult to predict because of technological, market, regulatory, infrastructural, economic and geopolitical uncertainties.

These uncertainties put pressure on onshore staff like fleet managers because they need to be able demonstrate, or at the very least estimate, what it will cost to operate a ship on sustainable fuels, for example over a ten-year period.

How to solve the challenge

In addition to modern, multi-fuel engines there are several other options available to reduce emissions and optimise fuel consumption and costs. These options include:

- adopting energy-saving propulsion systems,

- implementing energy-saving technologies such as an innovative pre-swirl stator, rotor sails or an energy-saving propeller cap, and

- choosing electrification solutions such as hybrid, shore power and shaft generators.

However, these solutions do not necessarily eliminate the challenge of predicting costs in advance.

Many OEMs offer service agreements that come with fixed or at least predictable costs, allowing you to budget more accurately and avoid unexpected surprises. These agreements can also include services like predictive maintenance or data-driven maintenance planning – both of which can help to reduce your total costs even further.

Predictive maintenance services take advantage of vessel data to detect anomalies early on. This way, your crew can address these anomalies before they become major issues, reducing the risk of downtime and saving you money. Data-driven maintenance planning services make it possible to safely delay maintenance work until your equipment really needs it instead of following fixed maintenance schedules based on equipment running hours. This helps cut your maintenance costs and reduce your crew’s workload.

Some OEMs may be able to ease your financial burden by offering flexible payment terms. This will allow you to spread the cost over a longer period or pay in lump sums, for example whenever maintenance work is done.

Conclusion

Learning how to use a new sustainable fuel is about much more than just technology. Even though adopting a new fuel requires a lot of learning and new ways of working, with the right support and training the transition doesn’t need to be difficult or complicated. Wärtsilä is a highly experienced and competent OEM and can help you tackle all the challenges described in this article so you can onboard your vessel crew and onshore staff to a new fuel smoothly.

With Wärtsilä’s expert help your crew and onshore staff can learn gradually over time how to keep your equipment in top condition and build their competences through professional training and expert support. A well-trained crew also improves the overall safety of your vessel.

Looking for more practical tips that will help you better manage the lifecycle of your vessels and stay competitive? This article reveals the number one thing you can do for smarter ship maintenance. You’ll discover how to save money, increase reliability and improve safety onboard – among a host of other benefits:

What’s the number one thing you could do for smarter ship maintenance?

This article, describing the five biggest challenges you can face when onboarding your staff to sustainable fuels and how to solve them first appeared as a Wärtsilä Insights item.