If your vessel uses liquified natural gas (LNG), there’s always a small amount of the fuel that doesn’t burn in the engine and escapes with the exhaust gases instead. This is known as methane slip – a challenge that engine manufacturers like Wärtsilä have been working on reducing for years. What is methane slip, why is reducing it essential and what smart solutions are on offer for methane slip reduction?

When it comes to cutting the shipping industry’s emissions, sustainable fuels are key. To reach the IMO’s 2050 greenhouse gas emissions targets, LNG offers great potential as a natural bridge between traditional fuel oil and sustainable clean fuels. There are three main reasons for this:

- LNG has significant potential to reduce emissions. LNG emits up to 25% less GHG tank-to-wake (TtW) and up to 15% well-to-wake (WtW) emissions compared to traditional marine fuels for the same propulsion power. Looking beyond GHG emissions, LNG also cuts NOx emissions by around 90%, and almost completely removes SOx and particulate emissions.

- LNG is adaptable and proven in use. There are almost 900 vessels in operation that can operate using LNG as fuel with another 900 vessels on the orderbook.

- LNG is available at scale. There are over 200 active LNG bunkering locations worldwide.

The basics – what is methane slip and why should you care about it?

LNG is predominantly methane. If your vessel’s engines burn LNG as a fuel, most of the methane will be used up in the energy conversion process. However, some of the methane remains unburned and escapes into the atmosphere. This is known as methane slip.

There are also upstream methane emissions from the production and transport of LNG. If not addressed, these methane emissions reduce the climate-related advantages of LNG.

Methane is an extremely powerful greenhouse gas which remains in the atmosphere for about a decade – a much shorter lifetime than carbon dioxide. Cutting methane emissions is the strongest lever we have to slow climate change over the next 25 years, and it complements ongoing efforts to reduce carbon dioxide. The good news is that the technology is here to help.

Hand-picked content: Time to take another look at LNG conversion?

Is there any IMO methane slip regulation?

As it stands there are no international regulations on methane emissions from maritime vessels, but regulations will be in place from 2025.

From January 2024 the EU Emission Trading System (ETS) will be extended to all ships of 5,000 gross tonnage and above that enter EU ports. This means that ship owners must pay for their GHG emissions when transporting to, from or between EU ports. EU ETS is based on TtW emissions and will initially only cover CO2 emissions. However, from 2026 methane emissions will also be included.

Hand-picked content: How to prepare for the EU Emissions Trading System and save money

In January 2025 FuelEU Maritime, which aims to promote the use of renewable and low-carbon fuels, will come into force. Non-compliance with the regulations will have a direct financial impact for ship owners. FuelEU Maritime tightens requirements on WtW GHG intensity limits for fuel consumed on board compared to the 2020 reference limit – and methane emissions are included from day one.

In addition, the Marine Environment Protection Committee (MEPC80) has adopted a revised strategy to reduce GHG emissions to net zero by or around 2050. This compares to only a 50% reduction in its initial strategy. In practice, this means that future IMO regulations will also include methane emissions.

What causes methane slip in gas engines?

Although a lean-burn LNG engine uses up most of the methane contained in the fuel in the energy conversion process, some of it remains unburned. There are three main sources of unburned hydrocarbon emissions in these types of engines:

- Flame quenching in crevices (level of methane slip does not generally vary with engine load)

- Flame quenching in the bulk charge (level of methane slip varies with engine load, with higher engines loads resulting in less methane slip and vice versa)

- Scavenging losses (level of methane slip does not generally vary with engine load).

How can you reduce methane slip?

There are two main ways to reduce methane slip for current vessels: you can upgrade your engines or reduce your fuel consumption. After all, the greatest emissions savings come from the fuel you don’t use.

The webinar How to reduce methane slip – winning tactics for your maritime business shares five great ways to reduce methane slip:

- Keep your vessel well maintained

- Avoid operating at low load

- Reduce the power needed for propulsion

- Optimise your engines

- Design your newbuild with flexibility in mind.

Watch the full webinar recording to learn more about each of the five winning tactics.

A quick and easy upgrade on your existing engines could cut methane slip by up to 65% depending on the engine type and load. Learn more: Upgrades to reduce methane slip from LNG engines.

Does reducing methane slip have to involve a lot of costly engineering work?

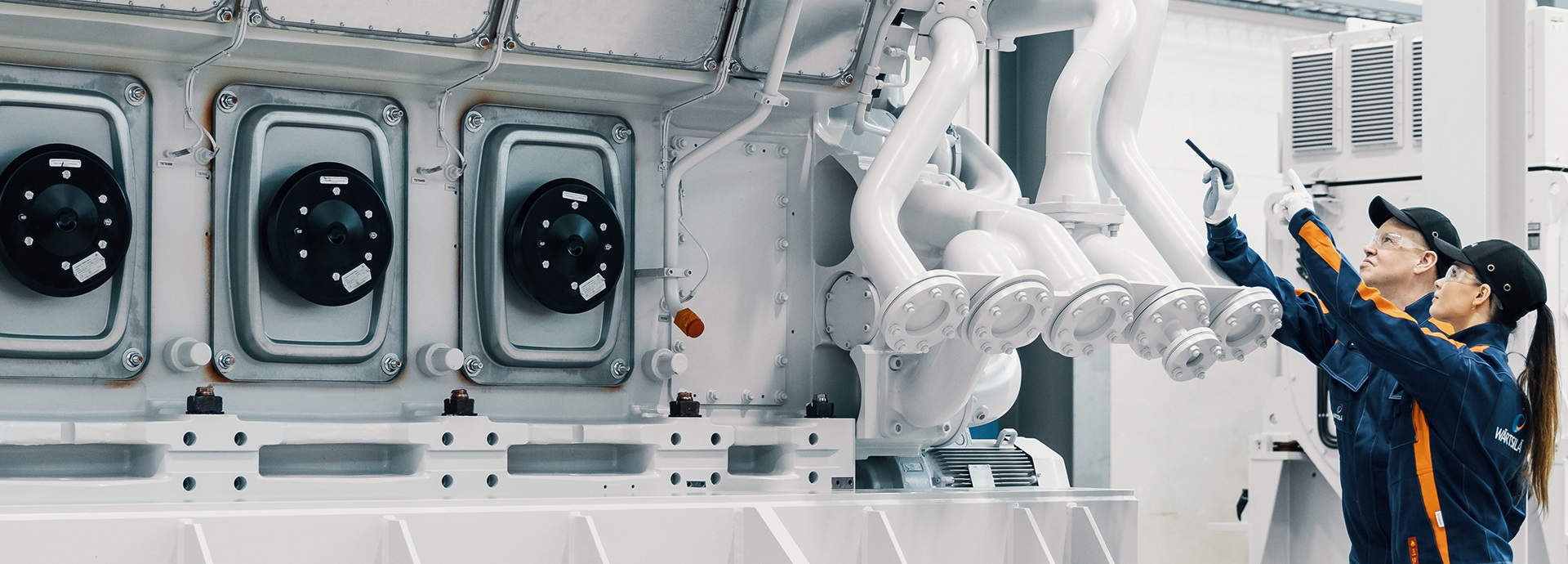

It might surprise you to learn that that addressing methane slip does not need to involve lots of time-consuming and costly engineering work. If your vessel is already powered by a Wärtsilä dual-fuel engine, a single field service technician and their laptop could be all that’s needed for a cleaner, greener machine.

Hand-picked content: A cleaner, greener machine – Wärtsilä 34DF control software upgrade cuts greenhouse gas emissions

The software upgrade – which is available for Wärtsilä 20, 34 and 50 dual-fuel engines – works by marginally reducing the engine’s charge air pressure and lambda – the air-fuel ratio in the combustion chamber. It is quick and easy to install and can cut methane slip by up to 60% when your engines are operating in gas mode below 85% load.

How can you future-proof a newbuild vessel?

The key to future-proofing newbuild vessels is to design with flexibility in mind. Newbuilds should be designed so they can be modified, with modular elements that can be updated when required. If the design process is outsourced, the designer may simply choose the cheapest or easiest options and not consider future requirements and flexibility. Ship owners should clearly state their own vision when starting the design process.

Dual-fuel engines are a good option for fuel flexibility. They allow you to adapt to different circumstances – they are also a great example of the benefits of being able to upgrade to the latest technology. Manufacturers have been working hard to reduce methane slip since the 1980s. For example, compared to the 1993 levels, Wärtsilä has cut methane slip from its dual-fuel engines by more than 90%.

A significant step forward has been the NextDF feature which can be applied to the Wärtsilä 31DF and Wärtsilä 25DF engines which already achieve very low emission levels. Combustion process innovations reduce methane slip remarkably, and yet the engines will provide the same, high power output as before.

The NextDF feature can reduce the methane slip of Wärtsilä 31DF and Wärtsilä 25DF engines to below the FuelEU Maritime regulation of 3,1% of fuel use.

- Find the facts on the NextDF feature for Wärtsilä 31DF

- Find the facts on the NextDF feature for Wärtsilä 25DF

Want to find out how to minimise methane slip and other emissions? Discover 50 great ways the maritime industry could reduce its greenhouse gas emissions.