Wärtsilä has carried out more than 100 installations of its container solution SamCon for ‘cold ironing’ to connect cargo ships to local power sources at California’s ports.

It’s rare that the muscular Hollywood movie star Arnold Schwarzenegger has a direct influence on Wärtsilä’s business. But in 2006 ‘The Terminator’ took the decision as Governor of California to promote shore power, known as ‘cold ironing’, to reduce air pollution and greenhouse gases from the state’s ports. As a result, California became a global centre of shore power, producing a boom in business for the cold iron specialist Wärtsilä SAM Electronics.

Cold ironing is the process of providing electrical power from the local grid, to a ship at berth in a port while its engines are turned off. It allows refrigeration, heating, lighting, and other equipment, to receive power as it unloads. One reason Schwarzenegger was anxious to promote it is that merchant ships use ‘bunker fuel’, which has high particulate matter and has been linked with thousands of deaths a year from heart and lung disease. Shore power comes from ‘cleaner’ sources. Many ships are equipped to carry out the process when built, but others have to be retrofitted.

“Schwarzenegger realised there were high levels of diseases linked to pollution in California. LA is especially bad as it’s in a bowl and pollution gets trapped,” says Jürgen Zabel, Senior Manager, Power Conversion, Wärtsilä SAM Electronics. “As a result of his legislation, we’ve carried out 100 retrofits for ship owners going into ports of California.”

Connection solution

First container solution

The cruise industry was the first to implement cold ironing, in Alaska, in 2001. Three years later, LA started to use the process for commercial ships and around the same time, SAM Electronics produced the first ‘container solution’. Unlike many competitors, Wärtsilä provides a full installation of its SAMCon shore connection equipment. Customers include major shipping companies carrying cargo from Asia to the US.

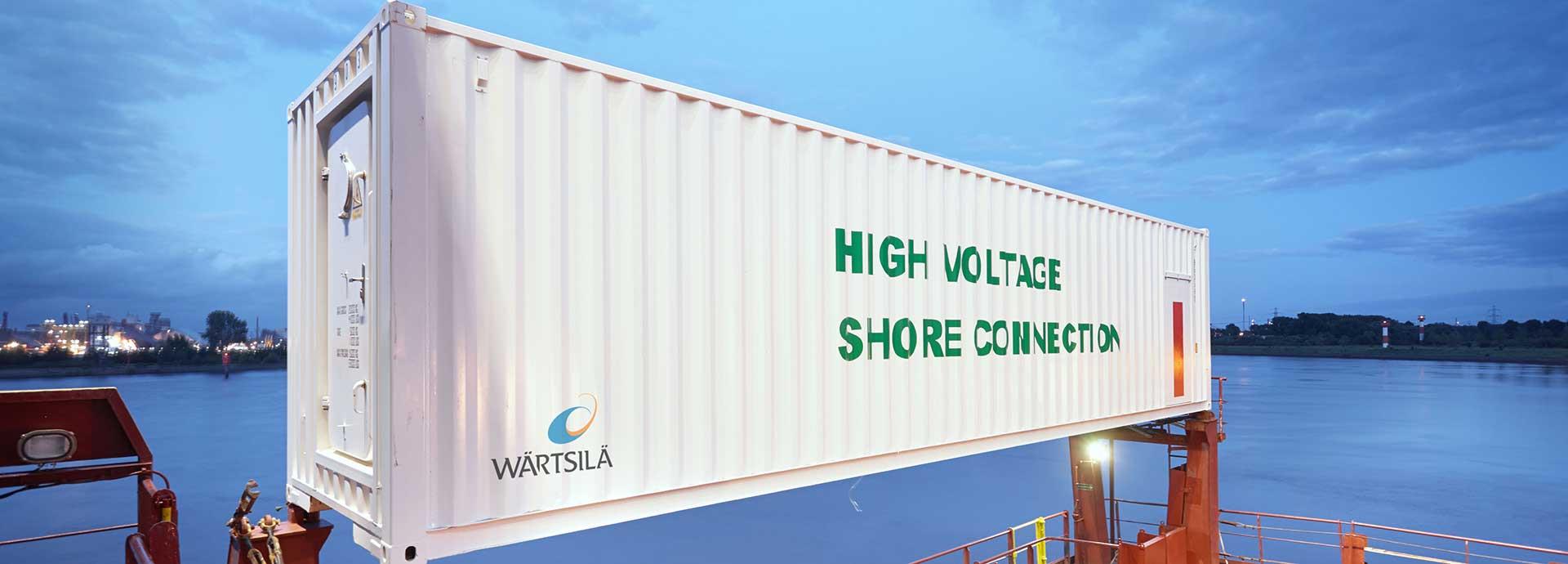

Teams of around six retrofit vessels with the Wärtsilä SAMCon system en route to California. Parts are pre-manufactured and slotted into containers, which are delivered to ships. The teams install cable trays, including hot works, and the complete power cables and connect them to the SAMCon containers, which include cable reels, high voltage switchboards and control units. The standard container size is 40ft, but they can be shrunk to 20ft if there’s a lack of space.

Connection between container and ship: bolted type

Flying to China

Wärtsilä has to be flexible as ship owners change routes at short notice and the teams could be asked to fly long distances. “Ideally, we install equipment in dry dock in Europe, but it usually doesn’t work out that way,” says Zabel. “Ship owners don’t like taking a vessel out of service which means we need to be flexible on where we load equipment and how we install and commission the equipment. Our teams often meet a vessel at port in China where they load installation material and then stay with the ship to install the equipment on route to California.”

Although many components are standardised, each vessel has different requirements necessitating a survey to ensure that the upgrade is “right first time” and meets the vessels power requirements. Once completed, the ships are free to sail to one of California’s ports, namely San Diego, LA, Long Beach and Port Hueneme.

The ship owners tend to upgrade their vessels for regulatory reasons, rather than to reduce emissions or operating costs. “If they don’t follow Californian regulations, they get hit by huge fines,” Zabel adds.

Connection between container and ship: bolted type

New markets

California continues to set the pace. By 2014 ships without a shore connection were banned in California and by 2020, 80% of power used by berthed ships will have to come from shore-side electricity. Few places have such a strict regulatory regime as California, however, and in 2012 the International Maritime Organisation (IMO) discussed making shore power mandatory at all the world’s ports. At the time, the IMO concluded there were not enough ports - only around 20 - ready with the technology to make it viable. Outside the US, several ports in Scandinavia have shore power, but they serve the ferry industry, which requires a different type of installation. Wärtsilä also offers innovative cold ironing solutions for ferries and cruise liners.

In future, EU directives will oblige member states to implement alternative infrastructure networks, including shore power by 2025. The EU will provide 50% funding as it can cost millions of euros to equip a port. Long-term, the IMO’s Marpol 6 regulations, which aim to progressively reduce the emission of fuel particulates NOx and SOx, should also encourage shore power. Meanwhile, the Chinese Government has recommended cold ironing is part of the construction for all new bulk and cruise terminals.

“In future, Europe and China are expected to tighten port regulations concerning emissions which will necessitate universal adoption of shore connection systems. We have been innovative and flexible in our approach which has led to growth in our new markets for cold ironing,” says Zabel.

Connection between container and ship: plugged type

Connection between container and ship: bolted type

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.