As the maritime industry accelerates its transition to low and zero-carbon alternative fuels, NextDF offers an innovative solution to reducing engine emissions and complying with increasingly strict legislation. What is the secret behind its success?

Cutting greenhouse gas emissions is a top priority across the maritime industry. Liquid natural gas (LNG) is widely recognised as the bridge fuel of the future for vessels – a good first step on the journey towards low and eventually zero-carbon alternative fuels. After all, LNG produces less greenhouse gas emissions and other harmful pollutants than heavy fuel oil (HFO).

For example, LNG produces:

- virtually no sulphur and particulate emissions

- approximately 90% less nitrogen oxide (NOx) emissions than HFO

- up to 25% less tank-to-wake greenhouse gas emissions than HFO.

However, the main component of LNG is methane, which is an extremely powerful greenhouse gas. If your vessel burns LNG as fuel, a small amount of methane escapes unburned into the atmosphere. This is known as methane slip. Although methane slip from modern engines is relatively small, if not addressed it reduces the climate-related advantages of LNG. NextDF technology is here to help with that challenge.

What is NextDF?

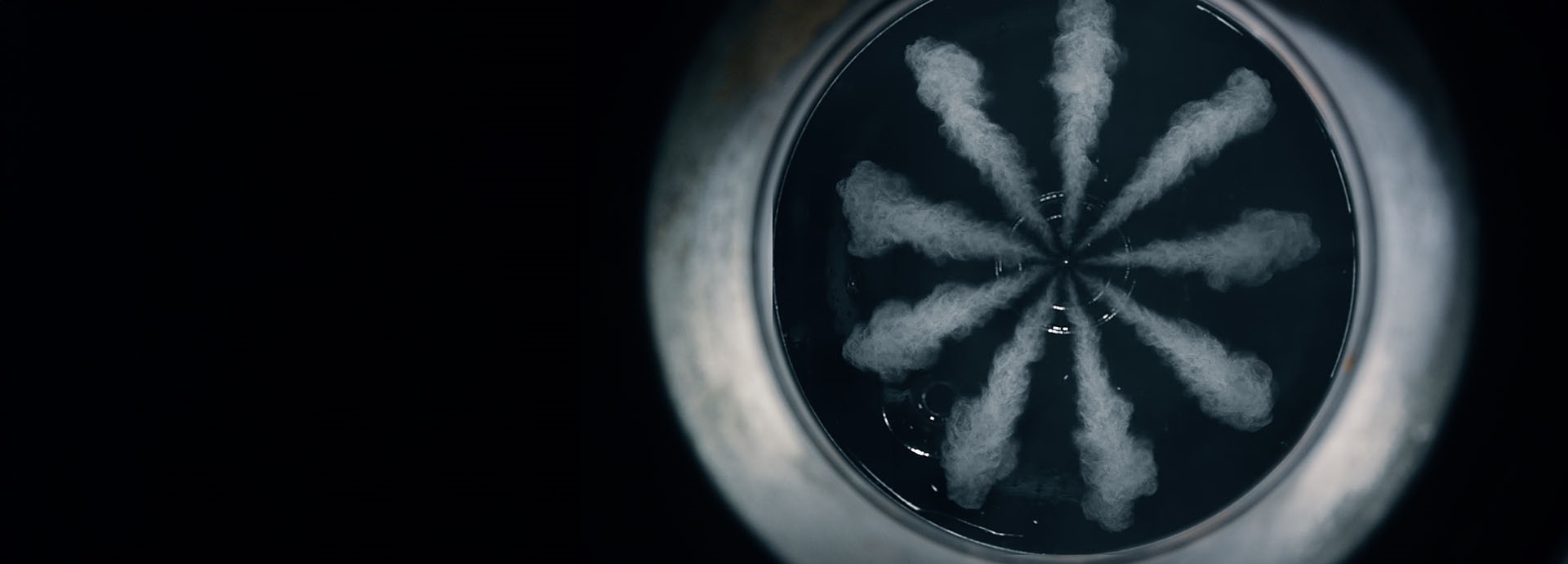

NextDF is an innovative combustion technology that dramatically reduces methane slip and minimises emissions of nitrogen oxides (NOx), CO2 and other pollutants. It does this by improving combustion control and optimising engine performance.

NextDF reduces the environmental impact of vessels that use LNG as fuel, without compromising on performance or operational stability. The smaller environmental impact also makes it easier for vessels to comply with ever-tightening emissions regulations.

How does NextDF work?

NextDF is packed with great examples of smart technology use. These include:

- Advanced combustion control: NextDF uses a closed-loop combustion control system based on real-time data from in-cylinder pressure sensors. The system continuously adjusts the combustion process to account for changes in fuel quality, air temperature and pressure. Because combustion is stable and efficient, NextDF minimises the chances of unburned methane escaping into the atmosphere.

- Hardware modifications for enhanced efficiency: The valve timing, compression ratios, piston top shapes and injector specifications have all been redesigned to improve operational reliability across a wide power range. Thanks to these adjustments, a NextDF engine can handle a broader variety of operational conditions while maintaining optimal combustion, minimising methane slip.

- Air-fuel ratio optimisation: NextDF engines have a higher air-fuel ratio compared to standard dual-fuel engines. This lowers their peak combustion temperature, which significantly reduces NOx formation and helps to minimise methane slip.

These innovations mean NextDF can:

- reduce methane emissions to less than 2% of fuel use across all load points

- achieve a reduction in NOx emissions of up to 95%.

The faster and more repeatable combustion process also reduces hydrocarbon emissions and improves overall engine efficiency.

How was NextDF developed?

The beginning: Wärtsilä began developing NextDF in 2017 with initial tests on a research engine. The technology was scaled up as part of the SeaTech project, funded by the EU’s Horizon 2020 research and innovation funding programme, which recognised the significance of the innovation.

Piloting: Pilot tests were carried out as a crucial part of the GREEN RAY project, also funded by Horizon 2020. The project aimed to develop and implement technologies that minimise methane emissions from LNG-powered vessels.

Full-scale testing: NextDF technology was piloted on the Aurora Botnia, a RoPax vessel operating between Vaasa, Finland and Umeå, Sweden. The key goal was to validate the new technology in real-world conditions. The tests confirmed that NextDF significantly reduces methane slip and emissions while maintaining operational stability, even under varying environmental conditions. The technology demonstrated improved engine performance too.

Technical validation: An independent third party, VTT Technical Research Centre of Finland, validated the test results, confirming that the improvements in emissions reduction were accurate and reliable. NextDF technology was shown to achieve a 10% reduction in GHG emissions. You can read more about the field testing in VTT’s report.

When will NextDF technology be available?

The first Wärtsilä engines featuring NextDF are already available: the Wärtsilä 25 NextDF and the Wärtsilä 31 NextDF.

These engines already have the best emissions performance on the market in both of their categories and easily meet current regulatory requirements. The Wärtsilä NextDF technology takes their emissions levels even lower.

The innovative NextDF combustion technology also means there is no need for additional methane abatement technology, saving space, weight and energy onboard.

What’s next for NextDF?

Because NextDF drastically reduces methane slip from LNG-powered engines, it provides a huge advantage for owners and operators of ships that use LNG as fuel. NextDF means owners and operators will be able to meet increasingly strict emissions regulations while benefiting from increased engine efficiency.

But NextDF isn’t just a solution for ships that use LNG or bio-LNG. When the time comes to switch to alternative fuels like e-methane and potentially hydrogen and ammonia, NextDF holds plenty of promise. The technology’s flexible hardware and advanced combustion control make it a versatile platform for alternative fuel concepts. This adaptability will be crucial as the maritime industry moves towards cleaner and more sustainable fuels. NextDF isn’t just a solution for today’s emissions challenges – it is a key enabler for the future of greener shipping.

Ready to reduce your emissions while powering the ships of tomorrow? Find out how bio-LNG is the bridge fuel of the future – and how NextDF will be an essential part of the transition.

This article, describing how NextDF technology is a way to dramatically reduce emissions such as methane slip first appeared as a Wärtsilä Insights item.