Wärtsilä’s decarbonisation experts use advanced technology to create and implement decarbonisation roadmaps with energy asset owners.

You know where you want to go, but you have to plan how to get there. Wärtsilä’s Decarbonisation Services uses advanced tools so companies can create and implement a decarbonisation roadmap for their energy systems, saving money and lowering

emissions while maintaining reliability.

“We use operational optimisation modelling and dynamic simulations, which work together,” explains Ella Teperi, Manager, Market & Financial Analysis at Wärtsilä Energy. “Operational optimisation modelling

determines the optimal capacity mix and dispatch logic to lower costs and emissions. Dynamic simulations look at loads and specific events to verify reliability.”

Power system modelling includes operational optimisation modelling and dynamic simulations. Modelling system capacity could use a up to a thirty-year time horizon, optimising the energy mix over time. This could show different steps to take to economically

lower emissions, such as adding renewable generation or energy storage in progressive steps. Yet we also need to consider what could happen as a result of these actions down to a millisecond scale. Dynamic simulations make stability calculations to

ensure that we maintain system technical compliance under a variety of conditions.

“To decarbonise you need to understand how your system works today and create a map of how you want it to work in the future. How do you reach your targets and keep reliability?” says Teperi. “And, of course, we don’t just provide

a plan. We also help energy asset owners implement it.”

Optimise – verb; make the best or most of

Wärtsilä uses an advanced energy modelling and forecasting software platform which examines costs and emissions in different scenarios. The platform is used to understand on a detailed level how to optimise emissions, fuel consumption, costs

and reserves over time.

“We have been using PLEXOS for more than ten years. We have modelled more than 1,500 different projects in more than 150 different countries, ranging from microgrids to continent-wide systems,” says Oula Lehtinen, Power System Analyst at Wärtsilä Energy.

Modelling shows us how to optimise dispatch and unit commitment based on available assets and operating costs. For instance, an unoptimised system may maintain unnecessarily high spinning reserves, resulting in higher fuel consumption, more running hours and higher emissions. An optimised system will meet reliability and spinning reserve requirements while minimising operational costs such as fuel, lube oil and maintenance.

Make decisions based on hard data

“Modelling starts with understanding the system as it is today,” says Lehtinen. “For that purpose, we and the customer collect system data, which includes all the basic information such as performance data of the existing assets, historical load data and fuel prices. We have thorough discussions with those who know the system to make sure we understand all the relevant operational aspects that need to be considered in the modelling.”

For the process to work properly it needs relevant data and realistic assumptions. Wärtsilä works closely with companies, sharing data to make sure the modelling has inputs they can trust. Lehtinen says that he has only had good experiences with customers who understand the importance of using high-quality information.

Perhaps one of the biggest strengths of our modelling is the holistic approach.

“Modelling enables data-driven decision making. With our modelling, the asset owners can be confident that the right decisions are made and no opportunities missed,” he explains. “Perhaps one of the biggest strengths of our modelling

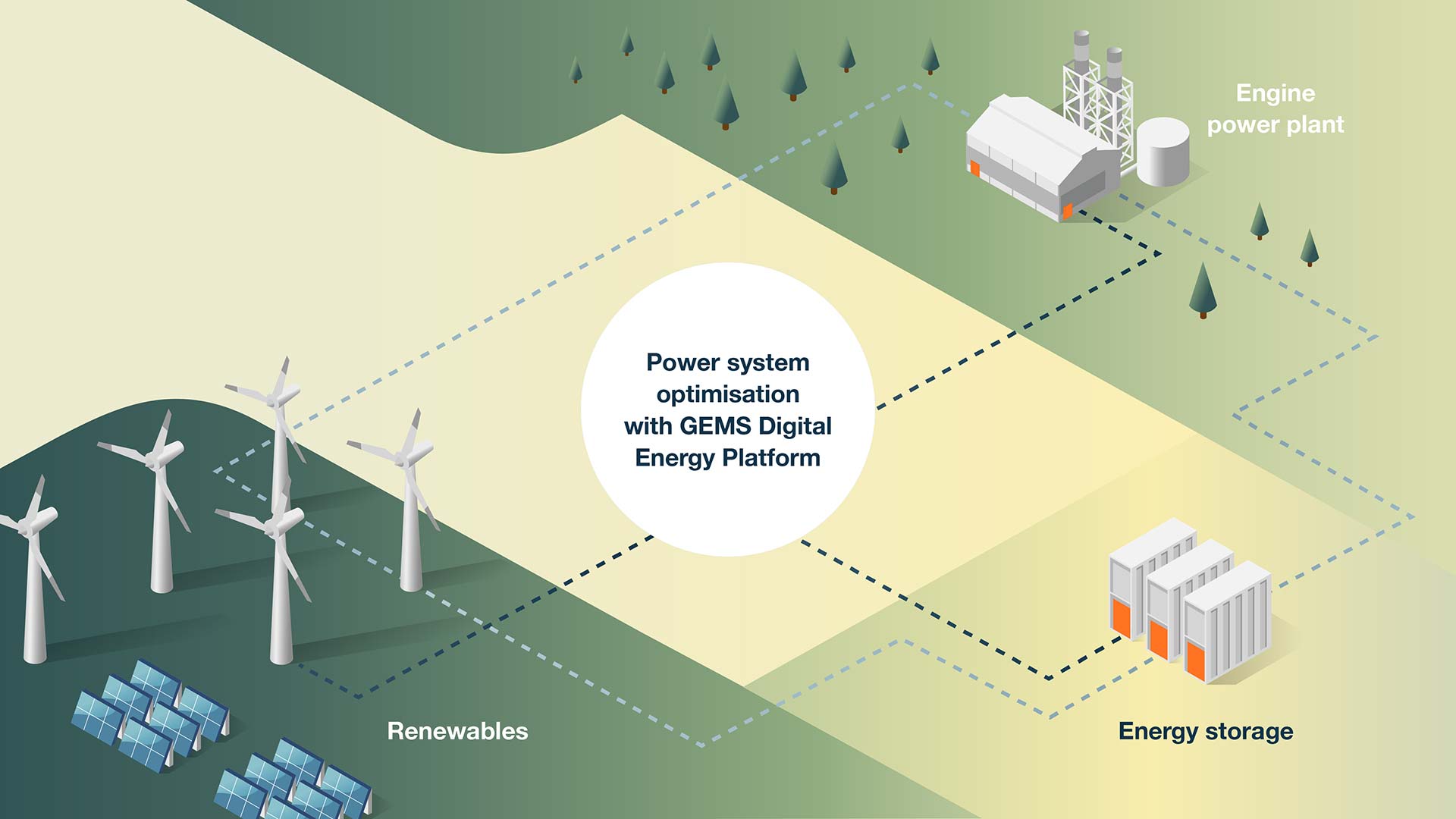

is the holistic approach. We use chronological dispatch modelling, which is especially useful in hybrid systems because it can capture and quantify the synergies between different assets, such as solar, wind, energy storage and balancing engines.

Looking at these technologies as separate entities without their interactions would not reveal their total contribution to system value and reliability.”

Maintain reliability and stability

Modelling might lead to a decision to change the mix of assets, such as adding wind and solar generation and retiring coal plants. Renewables are often cheaper and don’t release CO2 like fossil fuel plants, so this could improve profitability and

sustainability. Yet renewables provide power intermittently and will introduce instability to a system. That is where dynamic simulations come in.

“We do simulations to ensure the stability of the grid is maintained,” explains Stefan Schleeh, General Manager, Power Systems at Wärtsilä Energy. “We look at potential events in the power system from minor

incidents to worst case scenarios. We create events virtually and see how the system behaves. From this we can see what improvements are needed.”

Dynamic simulations analyse loads and identify stability boundaries of the power system. It sees how the system manages different events, such as when the largest unit starts, largest unit trips, largest load is lost, and grid separation and resynchronisation

occurs.

Be confident thanks to dynamic simulations

“Simulations are done so you are sure your plan will work, that you can rely on the solution,” Schleeh says.

Simulations can help ensure the holy grail of power systems: reliability. Dynamic simulations are done to verify the solutions Wärtsilä propose will work in practice. If you look at everything that could go wrong and then take steps to avoid

or mitigate them, you can trust following the steps laid out in your decarbonisation roadmap.

“Reliability is directly connected to costs,” Schleeh says. “An event could cause a blackout for just a few minutes, but it could take a big mine hours before its operations return to normal. That will cost an enormous amount of money.

Avoiding one blackout could save a company much more money than a host of efficiency improvements.”

Wärtsilä is a partner for the long haul

Wärtsilä helps build a bespoke plan to meet a company’s decarbonisation goals. Modelling and simulations do not come with extra charge, as it is part of the Wärtsilä Decarbonisation Services. But what could go wrong if you don’t

do modelling and simulations?

“If you don’t model and simulate different scenarios you’re risking reliability, making suboptimal investment decisions, and your system might not be operating optimally,” Teperi explains. “You need to study your system and what actions to take. You need to do it smart.”

Chronological dispatch modelling is especially useful in hybrid systems because it can capture and quantify the synergies between different assets, such as solar, wind, energy storage and balancing engines.

This is the old “look before you leap” proverb. One example of “looking” via comprehensive modelling resulted in a five-year roadmap for improvements. The first “leap” will add the Wärtsilä GEMS Digital Energy Platform, smart software that monitors, controls and optimises energy assets. GEMS enables a live system optimisation based upon different factors set with the consumer, while at the same time it has the potential to increase reliability. The next will add energy storage, followed by gas conversions of engines and finally adding more solar capacity and energy storage. In only five years the results will be dramatic: CO2 emissions reduced by 24.1% and costs down by 15%.

At every stage of this process Wärtsilä will be working to make sure good decisions are made based on hard data, so the solutions work and their cost, sustainability and reliability goals are met.

“Our roadmap is not just a theory or a hypothetical report,” Teperi says. “We have the skills and the technology to implement this today. Currently, we are working a lot with microgrids, owned by industrial companies or island grids, and our Decarbonisation Services help these players make and follow these plans.”