Much of the world relies on oil and gas as its primary source of energy – in the UK, for example, it currently powers around 75% of the country’s total energy needs, and it is clear it will be an essential part of the energy mix for decades

to come. At the same time, the UK is committed to being a net-zero greenhouse gas emissions economy by 2050. As a key player in the country’s economy, how can the offshore oil and gas industry reduce its production-related emissions while continuing

to supply the energy we all need?

Beyond the emissions we normally associate with fossil fuels – those that occur when they are burned – the production and processing of offshore oil and gas also have a role to play. For example, UK production currently accounts for as much as 4% of the country’s total greenhouse gas emissions. Reducing our reliance on fossil fuels may be the long-term goal, but oil and gas are essential to the security of energy supply and also significantly benefit the economy of producers. To tackle this challenge, the UK government announced its North Sea Transition Deal in March 2021, committing to reducing emissions in the oil and gas industry by 10% by 2025, 25% by 2027 and 50% by 2030. Reducing the carbon intensity of the industry might seem like a daunting task, but with the right expert support and an open minded, step-by-step approach, the industry can work together to achieve its goals.

Step one: take the easy wins

“In today’s competitive market, with increasing emphasis being placed on environmental performance, your assets need to be fit for purpose for the challenges ahead,” explains Tim Burnett, General Manager Market Innovation – Oil and Gas, Wärtsilä. For oil and gas stakeholders, improvements in operational reliability and efficiency translate directly to increased profitability and a more sustainable future. Engines and propulsion systems can often be upgraded, or improvement packages introduced to reduce emissions while maintaining efficiency. The latest advancements in digital technologies, machine learning, artificial intelligence and remote support are an effective way of future-proofing operations and ensuring assets are performing optimally.

Tim Burnett, General Manager Market Innovation – Oil and Gas, Wärtsilä.

Email: tim.burnett@wartsila.com

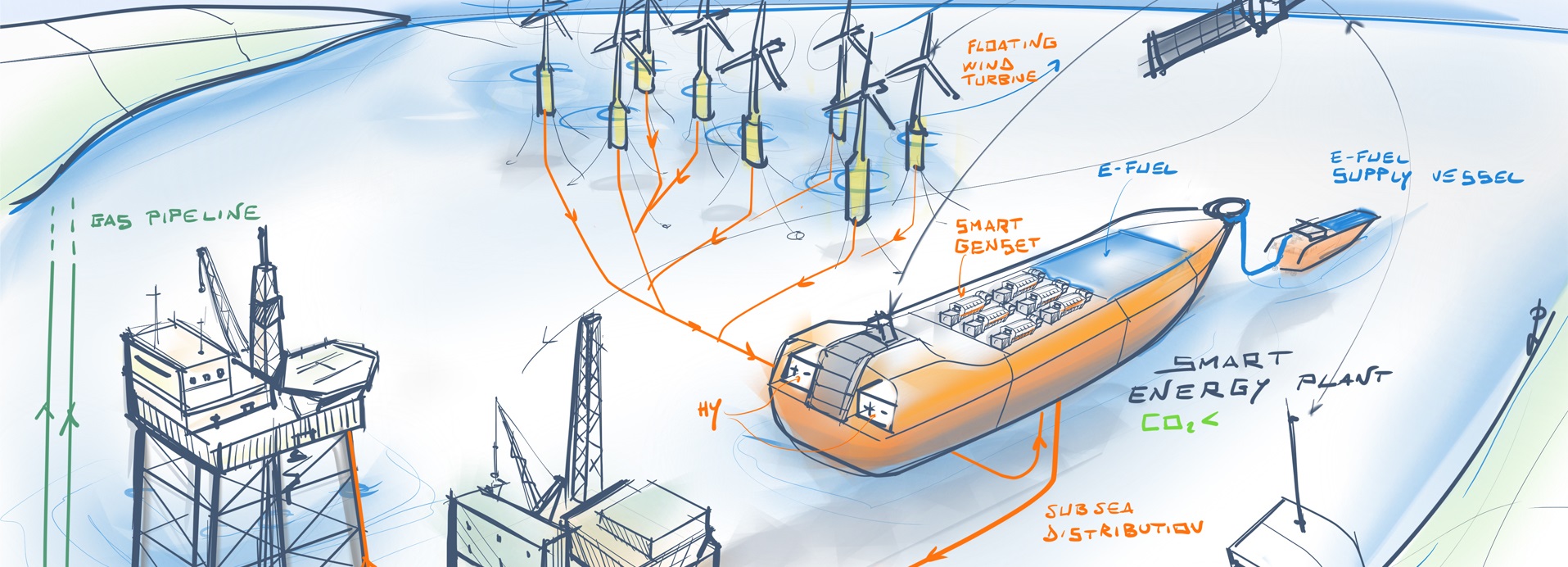

View our Offshore Energy Hub Concept Infographic

Step two: work together for a powerful result

While reaching a 10% reduction in carbon emissions should be achievable through relatively small, targeted actions, reaching 50% – and ultimately net zero – will require more dramatic change. Full electrification of individual North Sea installations

would require expensive power cables to be laid, and for some installations decommissioning may already be on the cards. But green power could still be within reach if we work together.

“Currently offshore power demands are met with gas turbines or diesel generators, both of which contribute to the production of CO2 emissions,” points out Tim. “One promising solution could be to identify a cluster of offshore fixed assets that are in close proximity, then deploy a number of floating wind turbines to generate enough baseload to satisfy their energy demands. This power would be routed to a repurposed floating production storage and offloading (FPSO) vessel or similar stable floating structure and then redistributed to the installations as required. Wind power will generate the baseload while our flexible 4-stroke power generating sets – adapted to run on the various future fuels under consideration – will provide the necessary flexibility, resilience and reliability for stable energy generation. Hybrid batteries can be used to allow a fast ramp up, perhaps supplemented with an energy storage system. This combination of technology turns the vessel into a floating energy hub, ready to meet all the power needs of the surrounding installations.”

Wind power will generate the baseload while our flexible 4-stroke power generating sets – adapted to run on the various future fuels under consideration – will provide the necessary flexibility, resilience and reliability for stable energy generation.

- Tim Burnett, General Manager Market Innovation – Oil and Gas, Wärtsilä.

A proven solution applied in a new way

All the technology for such a solution already exists and is in service today, although it is yet to be applied in the oil and gas industry. Wärtsilä already offers the floating power barge concept, a flexible solution that brings a fast supply of electricity to areas with limited infrastructure, with 26 installations globally providing a total power output of 1,500 MW. The system reliably meets the required energy needs and can be redeployed when requirements change. “When supplying power to oil and gas assets the energy hub should be anchored to the seabed, with subsea electrical cabling laid to each platform,” Tim clarifies. “That said, we would still consider the hub to be fully mobile long term, so if needs change it could be redeployed to other areas as required.”

The hub would have low maintenance and upkeep requirements as it wouldn’t require a permanent human presence. “The intention is for the hubs to be unmanned, with all control and monitoring activities transferred to an onshore control room using digital enablers which already exist,” explains Tim. “Our Expert Insight solution uses machine learning to enable better maintenance decisions, recognising anomalous behaviour before problems arise so the appropriate corrective action can be taken. As the asset would be operated as a Normally Unattended Installation (NUI), there is no requirement to have accommodation facilities or a helideck, although a safe refuge would still form part of the structure. By adopting NUI principles, maintenance would be carried out every six months with the asset accessed by means of a walk-to-work facility.”

Not just greener, but safer and more efficient too

“By centralising power generation in a floating hub, surrounding oil and gas installations no longer need to commit resources to maintaining their own alternative,” points out Tim. “Maintenance personnel are freed up to focus on other

areas and the reduced need for maintenance interventions could improve safety and reduce associated costs. As the remote energy hub contains all the required fuel for several installations, fuel bunkering is concentrated in one central location, reducing

the risk of environmental escapes. Some future fuels are deemed hazardous – this solution confines them to one remote location that is unmanned except for brief maintenance visits twice a year.”

Thinking further ahead, there are even more innovative developments possible. “Following the Siemens Gamesa concept of locally producing green hydrogen, one thought is that this could make the floating power hub concept self-sufficient,” suggests Tim. “This has already been considered for offshore wind supplying the grid, but it must be remembered that oil and gas applications generally have a constant demand for electrical power, unlike the domestic market where there is a reduction in demand at night. It remains to be seen whether locally produced green hydrogen would be an economical use of the power generated locally and depends very much on the volumes needed.”

Seeking innovative and visionary partners

Wärtsilä is heavily committed to helping the industry move towards decarbonisation and has invested significant resources into the use of future fuels in its 4-stroke products, working and co-creating with several industry leaders. “Wärtsilä benefits from the combined experience of our Energy division and our proud marine heritage, placing us at the forefront of innovative power generation solutions for the offshore oil and gas industry,” points out Tim.

Wärtsilä also has experience of putting together a partnership of cross-industry cooperation; it created the ZEEDS initiative, whose members are now actively working towards creating an entire ecosystem of offshore clean fuel production and distribution hubs and deploying them in strategic locations across the globe. Like our idea for offshore oil and gas assets, the ecosystem will be based on existing technology, meaning it is practical and can already be rolled out in pilot projects.

“Because no one does their best work alone, we are looking for visionary partners who would like to work with us to identify opportunities and refine the floating power hub concept to ensure it is the best it can be,” explains Tim. “In order to achieve net zero we all need to work together; collaboration and sharing best practice is key. Although we are focusing this solution on the needs of the North Sea basin, other oil and gas regions will surely benefit from these proposals. We’d be very happy to hear from any interested parties whatever region they are operating in.”

To discuss this topic further, please get in touch with Tim by emailing tim.burnett@wartsila.com