The pressing need to decarbonise is driving the short sea shipping sector towards increasingly flexible, electrified and hybridised solutions, with future fuel readiness also being built into newbuild solutions today. With a rapidly aging fleet, the sector must quickly embrace new propulsion concepts that will lay the groundwork for low and eventually net-zero carbon operations.

As well as global IMO regulations, owners in the short sea shipping industry are increasingly subject to new local emissions legislation depending on where their vessels are operating. In the EU alone there is the EU Fit For 55 framework, which involves the inclusion of maritime in the EU emissions trading system, the Fuel EU Directive and the Energy Taxation Directive. On top of imposing stricter requirements this legislation creates strong financial incentives for owners to get their house in order when it comes to decarbonisation.

The global short sea shipping sector is as diverse as it is vast, covering everything from small 3,000 dwt container ships and general cargo vessels to 30,000 dwt tankers and bulkers, handysize (<1000 TEU) containerships and heavy-lift and multipurpose vessels. The current global fleet comprises approximately 21,000 vessels, with Asia (11,000 vessels) and Europe (8,000 vessels ) making up the vast majority.

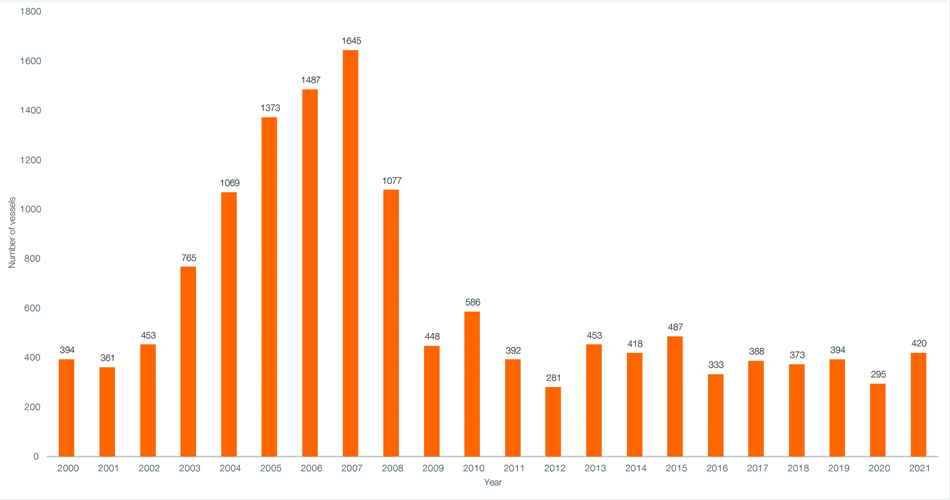

With little newbuild activity for several years the current fleet has an average vessel age of approximately 17 years globally, with close to 40% of the fleet being over 25 years old.

Number of vessels contracted 2000–2021. (Global small merchant 3–30k dwt, includes <1000 TEU container and <40,000 m3 LNG carriers)

“The need to decarbonise quickly combined with an aging fleet creates challenges but also great opportunities for ship owners in this segment,” says Grant Gassner, Director of Integrated Systems and Solutions at Wärtsilä.

Hybridisation takes hold

Recent ordering activity in the short sea segment indicates a clear movement away from the classic simple propulsion arrangement with a single main engine powering a fixed pitch propeller (FPP) towards hybridised and electrified propulsion solutions combined with alternative fuels, which provide owners with a solid, flexible foundation for the future.

“The market standard today is more towards established mechanical-hybrid setups consisting of one or two main engines, a controllable pitch propeller (CPP), a shaft generator with power take off/power take in (PTO/PTI) functionality, batteries and a shore connection. We have seen an increase in the requests for hybrid systems and have a current market share of over 20%,” explains Torsten Büssow, Director, Ship Electrification Solutions at Wartsila. “Alternative fuels are now considered in virtually all newbuild cases, with vessels being built with LNG readiness from day one and even with methanol or ammonia readiness designations.”

Hybridised and electrified propulsion solutions combined with alternative fuels provide owners with a solid, flexible foundation for the future.

For certain applications there is also increasing interest in fully electric propulsion setups because of the extra level of flexibility these offer in terms of vessel speeds and load profiles as well as for the integration of new energy-saving devices and energy sources.

“There is no right or wrong answer to the decarbonisation conundrum. The optimal solution will always depend on the owner’s requirements and decarbonisation strategy as well as key factors such as the vessel’s operating profile. In all cases it’s critical that the vessel designer, the owner, the shipyard and the OEM collaborate closely,” says Gassner.

Mechanical or electric hybrid propulsion – the choice is yours

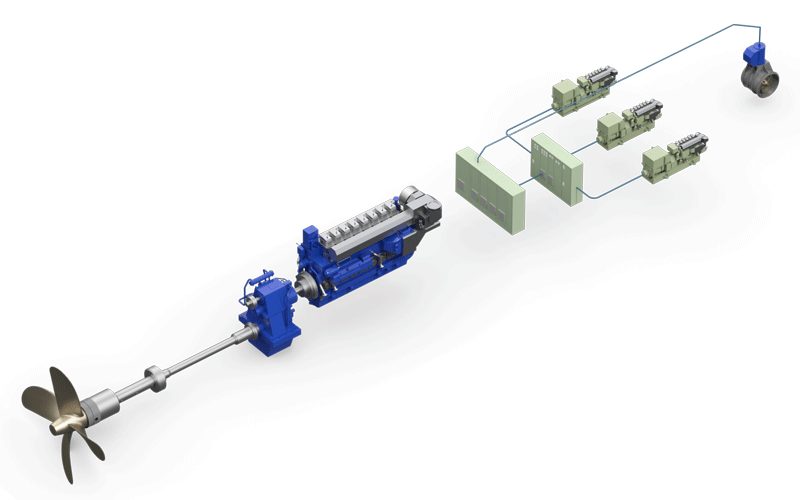

Traditional FPP arrangement for short sea shipping

Hybridised CPP

arrangement for short sea shipping

Hybridised CPP

arrangement for short sea shipping

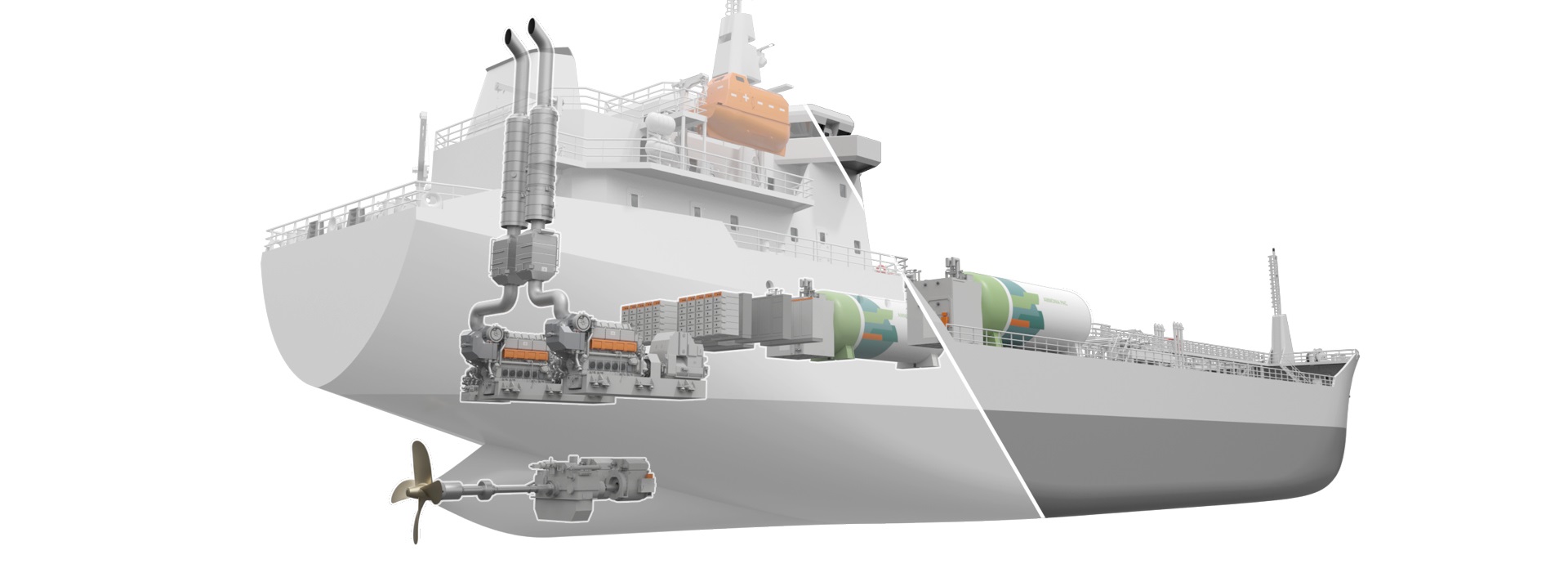

Wärtsilä has well-established concepts for both. In a mechanical hybrid setup one or possibly two engines provide all the required propulsion and auxiliary power for the vessel. There is a CPP, gearbox and shaft generator system with PTO/PTI functionality, via which batteries can supply both auxiliary and propulsion power. This setup makes it possible to decouple the main engine from the CPP and operate the vessel solely on battery power when entering and exiting port, eliminating emissions entirely.

Wärtsilä’s solution for short sea shipping guarantees full integration at the shipyard. This system is an efficiently integrated package with uniform documentation and single point of contact, where all equipment is engineered and designed to work together. The benefits for shipyard are reliability of delivery and lower overall cost considering the whole delivery process from integration design to project management, supply management, installation and commissioning.

The solution also provides a competitive edge for the ship designer with an efficient package and future-proof technology, strengthening the appeal of their proposed design.

In Wärtsilä’s 4-stroke hybrid electric concept multiple gensets cover the complete propulsion and auxiliary power needs through a common electrical distribution system. This offers exceptional flexibility in terms of the propulsion sources, which can be pods, azimuth thrusters CPPs or FPPs. Smaller engines combined with batteries typically run high load factors, leading to high efficiency and low emissions at all vessel speeds and power nodes.

Wärtsilä’s solution for short sea shipping guarantees full integration at the shipyard. This system is an efficiently integrated package with uniform documentation and single point of contact.

Standard, modular solutions that cut CAPEX and de-risk investments

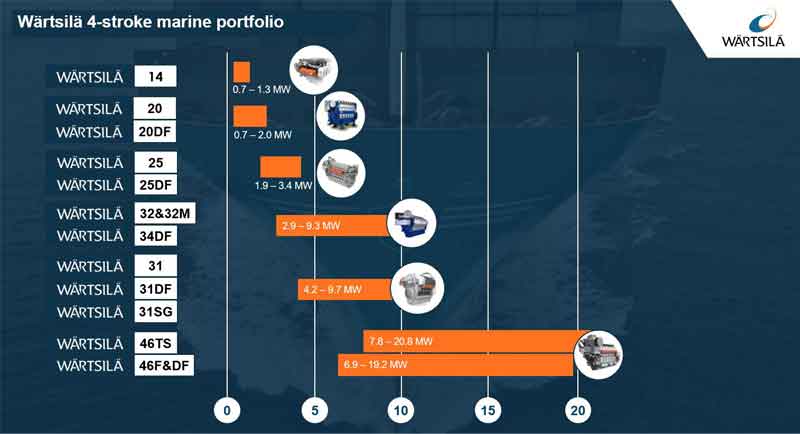

Wärtsilä’s modern engine portfolio includes a suite of new fuel-flexible engine families that cover the 1–10 MW power-range sweet spot of the short sea shipping sector. The new kid on the block is the Wärtsilä 25, a modular and future-proof solution that fits the core power demand of the sector well.

Wärtsilä’s 4-stroke marine portfolio

Wärtsilä’s 4-stroke marine portfolio

“Our proven technologies have been adopted by customers from all corners of the globe for a wide variety of vessel types,” Gassner highlights. “We have an exceptionally strong portfolio of cost-efficient, modular and scalable solutions that address the specific needs of the small merchant segment.”

Wärtsilä’s future-proof hybrid electric configuration

Smart integration is the key to success

Wärtsilä can support customers on their journey by providing a detailed analysis of why the proposed propulsion machinery system is the optimal one, including open and transparent benchmarking based on parameters such as GHG emissions, CAPEX, OPEX, and EEDI and CII compliance. This analysis is complemented with a detailed technical specification that presents the scope of supply to assist the customer in integrating the propulsion machinery system into their vessel specification.

Finally, a functional specification describes how the proposed propulsion machinery systems will be integrated and operate and details their functionalities and operational modes. This helps the customer to understand the full potential of the solution and ensure its successful integrated into the vessel design.

“Because we have extensive experience and the ability to offer a complete, integrated solution we are well placed to help the short sea shipping meet the challenges of the future. Our integrated solution offering covers engines, propulsion equipment, electrical systems and fuel gas systems,” Gassner says. “In a future where marine powertrains are set to become more complex, electrified and hybridised, combining smart integration and close collaboration will be a key success factor.”

Sign up for our Future-Proof Solutions for Short Sea Shipping webinar to discover how our flexible solutions can support your decarbonisation journey.

For further information please contact:

Torsten Büssow, Director, Ship Electrification Solutions, torsten.bussow@wartsila.com

Grant Gassner, Director, Wärtsilä Integrated Solutions and Systems, grant.gassner@wartsila.com

Related solutions

Did you like this? Subscribe to Insights updates!

Once every six weeks, you will get the top picks – the latest and the greatest pieces – from this Insights channel by email.