Are you looking for a way to reduce vessel emissions today, while still operating on conventional fuels? Onboard carbon capture and storage could help you do just that. Here are 17 interesting facts about a technology that is likely to play a strong role in the decarbonisation of shipping.

Onboard carbon capture and storage (CCS) – a technology based on liquid absorption – makes it possible to reduce carbon emissions by up to 70%. It can also be combined with abatement technology for sulphur oxides (SOx), nitrogen oxides (NOx) and particulate matter (PM). Discover how CCS works in these 17 questions and answers that reveal how the technology could benefit you.

1. What is carbon capture and why is it important?

Carbon capture is a method of capturing CO2 from fossil fuel after it is combusted in an engine, before it can be released into the atmosphere. The technology can also be used with fuels such as methanol to make them net carbon negative. It is an important new technology because it can be retrofitted to most vessels to immediately reduce carbon emissions. If a vessel currently running on fossil fuels were to install a carbon capture system with a 70% capture rate, it would be possible for that vessel to meet 2040 maritime decarbonisation targets from day one.

2. What is the difference between carbon capture and an exhaust scrubber?

Exhaust scrubbers remove SOx from exhaust gas, whereas carbon capture technology removes CO2 and temporarily stores it in liquid form.

Exhaust scrubbers clean the exhaust gas with seawater, removing SOx and cooling the gas down. Scrubbers also work as a platform for other technologies:

- A wet electrostatic precipitator (WESP), downstream from the scrubber, filters the exhaust gas to remove particulate matter.

- An exhaust gas recirculation system (EGR) reduces NOx emissions.

- A water filter can even be added to capture microplastics.

Exhaust scrubbers are an alternative compliance method for ships, allowing them to reduce emissions while still sailing on heavy fuel oil (HFO). As very low sulphur fuel oil (VLSFO) and marine gas oil (MGO) are both more expensive than HFO, the scrubber investment can potentially be recovered in fuel costs in as little as two years.

Carbon capture is another technology that can be added to the scrubber platform. Carbon capture removes CO2 and stores it as a liquid until it can be disposed of, rather than releasing it into the atmosphere. Land-based carbon capture systems have been used successfully for many years, demonstrating the maturity of the technology. An onboard carbon capture system could reduce a vessel’s carbon emissions by up to 70%.

3. How does a carbon capture system work?

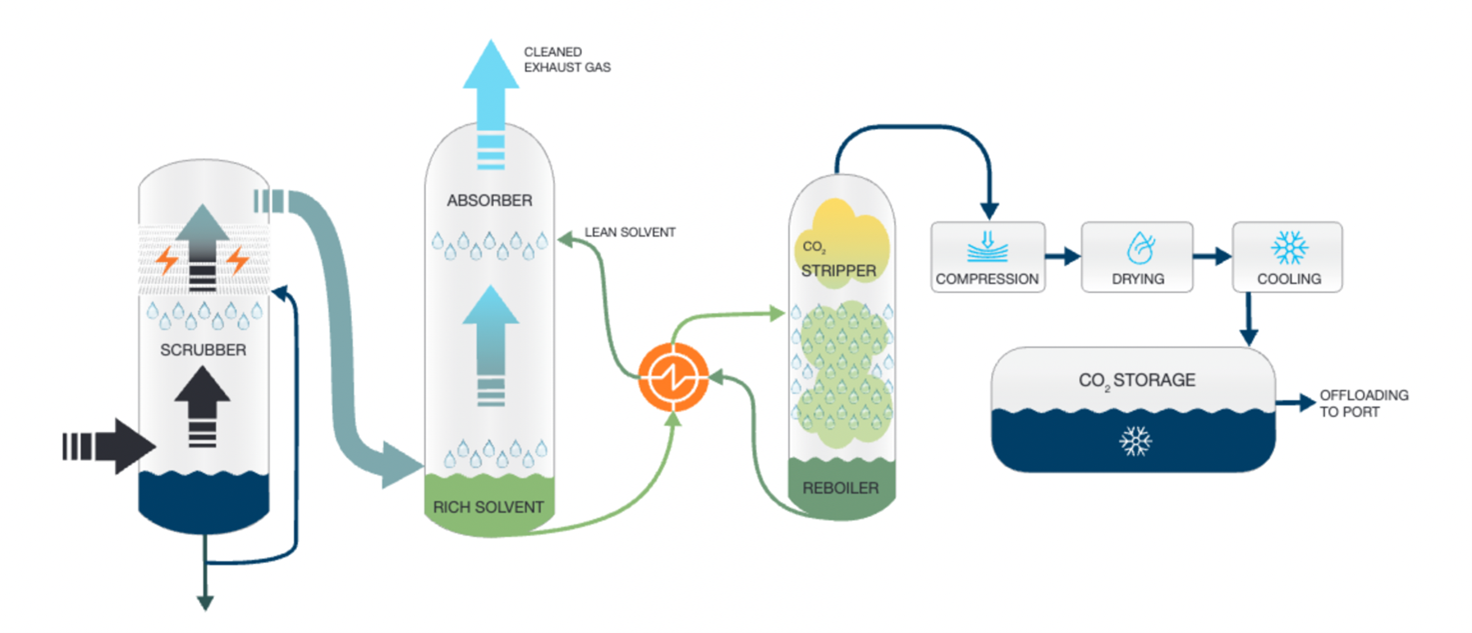

A carbon capture system has five main stages: pre-conditioning, absorption, desorption (or stripping), liquefaction and storage.

The first stage is the pre-conditioning. This is where the exhaust gas is cleaned and cooled down. For high-sulphur fuels this requires a scrubber to remove SOx and then a WESP to remove PM. The pre-treated exhaust gas then travels to the bottom of the absorber.

The second stage is the absorber. A liquid amine-based solvent enters the top of the absorber where the gas and solvent mix. This captures the CO2 in the solvent. The cleaned exhaust gas exits the system and the CO2-saturated solvent is pumped via a heat exchanger to the stripper.

The third stage is the stripper. The solvent is heated, releasing the CO2. The lean solvent is recirculated to the absorber and reused.

The fourth stage is liquefaction. The CO2 is compressed, dried and cooled down to liquid form for storage.

The fifth and final stage is storage. The liquid CO2 is pumped through pipes to onboard tank(s), where it is stored until it can be offloaded.

4. How can carbon be captured from exhaust gas?

There are several different ways to capture carbon from exhaust gas. Membrane-based systems have a large footprint and are energy intensive, so they are currently generally better suited to land-based carbon capture.

Companies such as Wärtsilä are exploring cryogenic and other novel carbon capture technologies for maritime use. These technologies have potential in the long term, but are not yet mature enough to be used on board ships.

Solvent-based technology is the most mature method for onboard carbon capture. This is based on factors including cost, scalability, ease of operation, maintenance, reliability and ease of integration.

5. Can carbon capture help reduce greenhouse gas emissions?

Carbon capture can help the maritime industry reduce greenhouse gas emissions. Vessel owners and operators have several options available to reduce emissions, from switching to non-fossil-based or low-fossil-based alternative fuels to adding energy saving technologies to their vessel. An onboard carbon capture system could reduce a vessel’s CO2 emissions by up to 70%.

6. How does carbon capture fit into the shipping industry’s decarbonisation strategy?

The IMO’s target is for the shipping industry to be carbon neutral by 2050. There are many possible ways to achieve this target, but they can broadly be categorised into three areas:

- Increasing energy efficiency

- Moving to lower-carbon alternative fuels

- Investing in abatement technologies

Different vessels will require a different combination of solutions. Some technologies are still being developed, while others are already available and economically viable. Rotor sails, for example, can reduce emissions by up to 7–8% and a new optimised propeller by 10%. Synthetic fuels, which have zero CO2 emissions from a tank-to-wake perspective, will be an essential part of decarbonisation. Many industry analysts predict that green synthetic fuels will become widely available at scale in the late 2030s and early 2040s. Existing ships will require significant retrofitting to take advantage of the benefits that these fuels will bring.

Carbon capture and storage (CCS) can be a key part of the shipping industry’s decarbonisation strategy.

7. Is carbon capture a viable solution for combating climate change?

Carbon capture is a viable solution to combat climate change – the technology for land-based installations is relatively mature, proven and commercially viable.

Policies and legislation may make carbon capture even more cost effective in future. This is what happened with scrubbers after the IMO 2020 legislation restricted sulphur oxide emissions.

CCS is a post-combustion solution perfect for vessels that are still using fossil fuels. The American Bureau of Shipping (ABS) expects fossil fuels to be part of the fuel mix to 2050 and beyond. This gives carbon capture the opportunity to play a significant role in decarbonisation. CCS makes it possible to reduce carbon emissions by up to 70%, supporting the industry’s 2040 decarbonisation goals.

8. How can I future-proof my vessel against tightening regulations?

There are two main ways you can future-proof your vessel against tightening regulations today. The first way is to install a fuel-flexible engine and related tank capacity so you are ready to use an alternative fuel. Another way to future-proof your vessel while you are still burning conventional fossil-based fuel is CCS.

A CCS system has the potential to achieve 70% carbon capture, but it could also be run to capture less, with correspondingly lower energy costs. Some owners might initially run the system to capture less carbon, then increase capture rates as regulations evolve. This approach would allow them to ramp up their emission reduction efforts gradually.

9. What are the ways to reduce SOx, NOx and particulate matter emissions?

The shipping industry is currently responsible for 16% of the world’s NOx emissions, 5% of the world’s SOx emissions, 2% of the world’s CO2 emissions (according to experimental estimates released by the Organisation for Economic Co-operation and Development) and a significant share of the world’s particulate matter (PM) emissions.

Scrubber technology can reduce SOx emissions by >97%, while providing a platform to reduce other emissions too. Building on the scrubber system, exhaust gas recirculation (EGR) can reduce NOx emissions by >80%, while a special filter (WESP) can reduce particulate matter emissions by up to 95%.

Handpicked related content: Interested in reducing your vessel’s SOx, NOx, PM and CO2 emissions? Discover more about reducing SOx, NOx and PM emissions and the science of onboard carbon capture and storage.

10. What are the benefits of carbon capture?

A CCS solution could potentially reduce a vessel’s carbon emissions by up to 70%. If every ship with a Wärtsilä scrubber installed a CCS solution, this could remove an incredible 30 million tons of CO2 from the atmosphere every year.

11. What are the challenges and limitations of carbon capture?

A wide variety of vessels can benefit from a CCS system designed for a straightforward retrofit. There are three main challenges to consider when deciding if the technology is right for your vessel. The first is that carbon capture comes with an energy cost. Vessels with a carbon capture system may choose to only capture as much CO2 as is needed to comply with regulations. This reduces the energy cost.

The second challenge is that a CCS system takes up space. In some cases this means some cargo space must be sacrificed. Individual operators can make their own cost-benefit analysis or ask their OEM to help them perform the calculation. Future legislation and carbon taxes will affect the payback time for a CCS system. The higher the carbon tax, the shorter the payback time.

The third challenge is what to do with the captured carbon. The industry is still debating who should take ultimate responsibility, but infrastructure is already being developed rapidly as CCS is being used in shore-based industries.

12. What happens to stored CO2?

Liquid captured carbon is stored in a tank onboard and then offloaded at port reception facilities. Shore-based carbon capture systems, such as those used in cement and fertiliser production, already transport their carbon to these ports. With some investment, this infrastructure could be adapted for the maritime industry.

Permanent carbon storage options are currently mostly in Northern Europe, with more emerging in North America. Captured CO2 can be permanently stored under the sea in depleted oil wells or saline aquifers.

Plans for CO2 storage sites in Europe are currently under development. It is hoped that there will be sites for permanent storage with capacity for over a hundred million tonnes of CO2 per year by 2030. The European Commission’s Net-Zero Industry Act includes the target for an annual CO2 storage capacity of 50 million tonnes by 2030.

Technological advancements have transformed captured carbon from a waste product to a valuable resource, with applications ranging from synthetic fuel production to enhancing agricultural yields and even serving as a raw material for consumer products like plastics. Captured CO2 can also be used in building materials and mineralisation, which is a form of permanent carbon storage.

The aim is for it to be possible to offload CO2 from a ship at the same time as other operations like bunkering fuel or loading or unloading cargo. This would be done at a port that provides the least possible disruption to a ship’s commercial route. According to a report by the American Bureau of Shipping, because most ships travel along the same corridors, 80% of maritime CCS needs could be covered by having facilities at just seven to eight ports.

13. What are the environmental impacts of carbon capture?

If all vessels currently sailing on fossil fuels were to install a CCS system with around 70% capture capacity, emissions could be reduced by up to 700 million tons per year.

14. How much does carbon capture cost?

It’s hard to put an exact price on the cost of carbon capture as it will vary by vessel, desired capture rate and storage capacity. Based on Wärtsilä’s own calculations, a rough estimate would be €50–70 ($54–$76) per ton of CO2 captured including CAPEX and OPEX. The CAPEX of a carbon capture system includes the cost of buying and installing the system; the OPEX includes crew attendance, solvents, energy consumption and servicing.

When considering cost, it’s worth comparing the cost of fuels and the need for vessel modifications. Low sulphur fuel oil (LSFO) is much more expensive than heavy fuel oil (HFO), and alternative fuels like methanol and ammonia are more expensive again, as well as requiring significantly higher storage capacity. Switching to alternative fuels is one excellent option to ensure compliance for your vessel. If this isn’t an option in the short term, installing a carbon capture system can ensure compliance while still sailing on HFO.

15. What is the fastest way to meet IMO decarbonisation targets?

There is no simple answer to the fastest way to meet IMO decarbonisation targets. Most studies conclude that the maritime industry needs to implement a range of technologies to reach climate goals, and carbon capture and storage could be one of these technologies. What is clear is that CCS has the potential to reduce a vessel’s carbon emissions by up to 70%, which would help reach the industry’s 2040 decarbonisation goals.

16. Has carbon capture been tested in practice?

Wärtsilä’s CCS system ran for three years at an onshore test facility before being installed onboard an LPG carrier operated by Norwegian shipowner Solvang Shipping.

Solvang’s 21k-cbm ethylene carrier Clipper Eris has been retrofitted with a CCS system for full-scale testing and optimisation. The pilot aims to achieve 70% carbon capture, which equals 50 tonnes of CO2 a day. The ship has storage capacity for up to 20 days at this capture level – equivalent to a trip across the Atlantic.

The carbon capture achieved helps ensure the vessel’s ongoing compliance with ever-tightening IMO decarbonisation targets.

Solvang is also looking to install the technology on the rest of its LPG carriers. In addition, Wärtsilä has carried out 16 feasibility studies for other operators on different types of ship.

17. Who can use carbon capture and how can I get started?

Carbon capture is suitable for both vessel retrofits and newbuild ships, particularly:

- Tankers

- Bulkers

- Container vessels

- Merchant vessels

- Offshore vessels

Any vessel that travels for longer distances could benefit from CCS technology.

If you’re interested in learning more about how a CCS system could support your decarbonisation efforts, feasibility studies are available today.

This article about carbon capture and storage for maritime applications first appeared as one of Wärtsilä’s Insights stories.