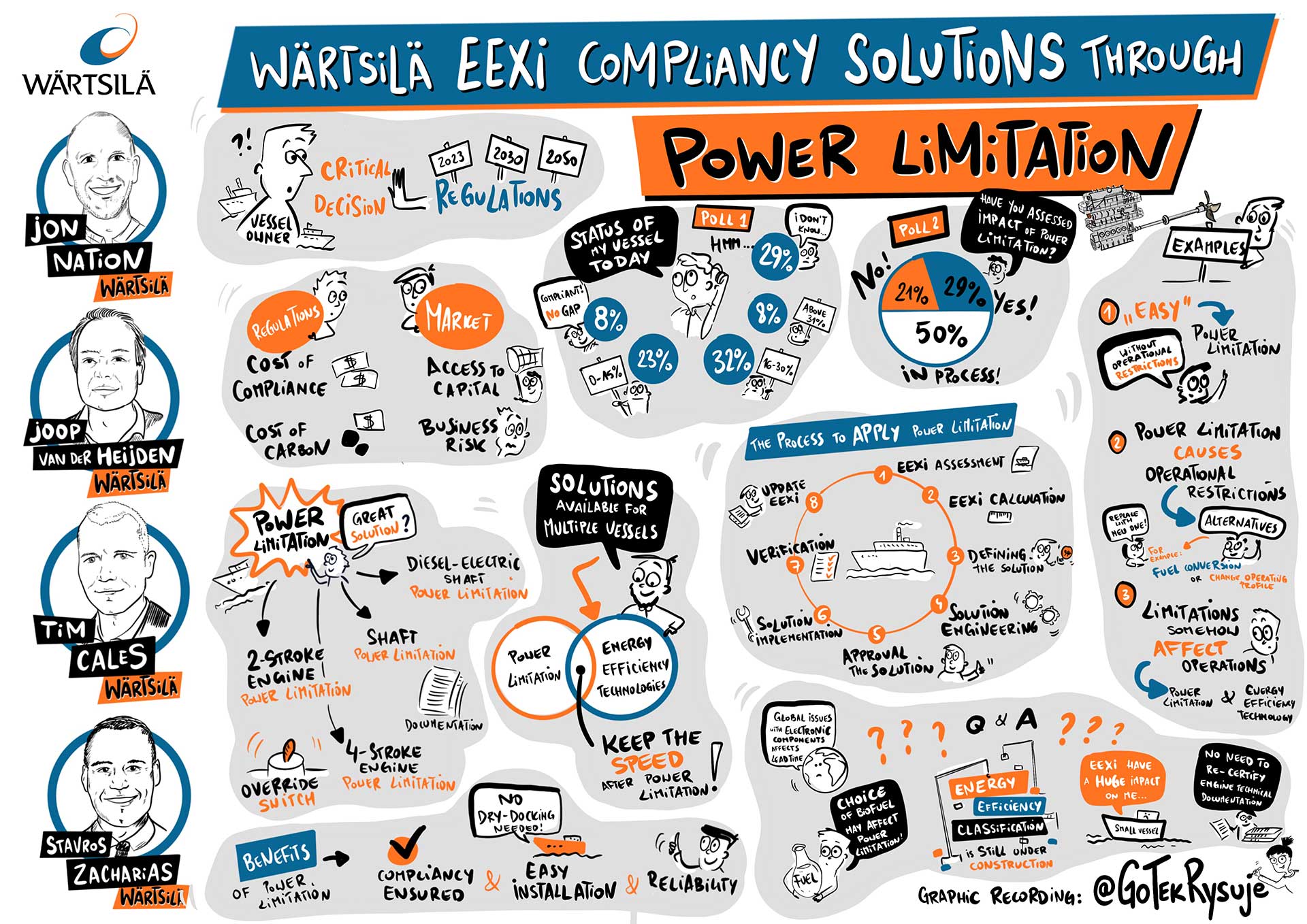

It’s no secret that Energy Efficiency Existing Ship Index (EEXI) regulations come into force at the start of 2023. But what is less clear for many is how to choose from the power-limitation solutions on offer to help ensure compliance on a tight schedule. In our recent webinar, three of Wärtsilä’s top experts in the field discuss the options open to vessel owners and provide some real-world examples to illustrate the practicalities.

The EEXI and Carbon Intensity Indicator (CII) measures that come into force in January 2023 are being implemented to support the International Maritime Organization’s goal of reducing the carbon intensity of international shipping by 40% by 2030 and 70% by 2050. Critical decisions about investments need to be made, and fast.

DNV survey estimates that a colossal 30,000 vessels will be non-compliant with EEXI should owners decide to take no action.

It’s no longer a question of if, but how.

There are always risks involved in big investment decisions, but Wärtsilä is well placed to help vessel owners mitigate those risks with proven solutions that quickly address the decarbonisation challenge. One size does not fit all – so our goal is to work with vessel owners who want to go down the power limitation route to identify the right solutions for them to ensure EEXI compliance. The optimal solutions will depend on a variety of factors, including the configuration of the vessel's drive train, the vessel age, its operational profile, the legislation gap and the sustainability strategy of your organisation.

As part of the webinar, participants were quizzed on their perceived EEXI compliance gap, with 32% rating the gap to compliance for their vessels at between 16 and 30% and, tellingly, almost the same number stating that they don’t know what gap they are currently facing. Joop van der Heijden, General Manager, Project Sales Support, Wärtsilä Marine Power, picks up the discussion to look at Wärtsilä’s basket of options for power limitation.

A quick and easy way to ensure compliance

“The poll results certainly reflect what we are hearing from our discussions with customers and, after a slow start, awareness is growing all the time. With 2023 just around the corner owners urgently need to start looking into this matter,” van der Heijden begins.

But what do we mean by power limitation? Put simply, it means reducing a vessel’s maximum sailing speed, and it’s a quick and easy method of complying with EEXI requirements because the main propulsion power is the biggest factor influencing the EEXI calculation formula.

Many vessels today are not sailing at their designed service speed anyway, so compliance can be achieved with little or even no impact on the operational profile,

he explains. “We offer solutions in the form of upgrade packages that can be tailored to fit any propulsion train design, covering 2-stroke and 4-stroke power limitation and shaft power limitation solutions.”

Power limitation solutions for 2-stroke engines

For electronically controlled Wärtsilä, WinGD and Sulzer 2-stroke engines with WECS or UNIC engine control systems, power can be limited directly in the system with the implementation of a software upgrade. For mechanically controlled engines Wärtsilä can install an engine power limitation (EPL) interface box which includes all the necessary hardware to interface with the engine.

The EPL, which remains in place at all times during normal operation, can be manually overridden via a switch on the bridge to allow for situations where a power reserve above the normal limit is required for the purpose of safely securing the ship, in man overboard situations or other purposes defined by the IMO. Any such override must be immediately recorded and indicated to the relevant classification societies. Wärtsilä’s solution includes automatic data logging to support operators in fulfilling this obligation. Both the override function and recording of override events are mandatory features stipulated by IMO / MEPC guidelines.

Power limitation for 4-stroke engines

The Wärtsilä 4-stroke Engine Power Limitation upgrade package is suitable for vessels with a single main engine per shaft line driving a fixed pitch propeller (FPP) but without power take-off (PTO) or power take-in (PTI). The solution can be installed as an add-on and has been designed in collaboration with one of the major classification societies.

The speed/load controller in the installed EPL control cabinet measures the instantaneous power delivered by the engine, while an engine control system software upgrade limits the actuator position when the power reaches the EPL set point. For mechanically controlled engines a governor upgrade performs the same function as the software upgrade.

As with our 2-stroke EPL solution, the set point can be overridden via a switch on the bridge for the purpose of securing the safety of a ship or saving life at sea and the solution includes automatic data logging.

Shaft power limitation (ShaPoLi) and diesel electric power limitation

For vessels with Wärtsilä-designed controllable pitch propeller systems, Wärtsilä can supply a verified and approved overridable ShaPoLi system that limits shaft power during normal operation. With this solution a torque measurement system attached to the propeller shaft sends a signal to the propulsion control system to limit the power at the shaft by limiting the pitch and/or rpm setting in a controlled manner.

As with our 2 and 4-stroke EPL solutions, the system has been designed together with a major classification society, can be overridden with a switch on the bridge and includes automatic data logging for reporting purposes.

One of the biggest advantages of this solution is that it does not limit operational flexibility for vessels with multiple shaft lines or multiple engines per shaft, or those with PTO and/or PTI systems.

For vessels with Wärtsilä diesel-electric propulsion systems Wärtsilä offers a software upgrade for the electric-motor drive systems to limit the maximum torque delivered by the motors. As with all the other EPL solutions, an override function and automatic data logging are included in the package.

Ensured compliance, easy installation and reliability

“The benefits of all our power limitation solutions can be summed up quite simply,” emphasises van der Heijden. “First and foremost, they offer a quick and easy way for vessel owners to ensure compliance with EEXI requirements. We have designed them to be very easy to install, with the possibility for the work to be done during a port stay rather than requiring expensive and time-consuming dry docking. Finally, reliability, which is always our number-one priority, has been a key factor in their design because it is critical to ensure stable, safe vessel operations.”

Combining power limitation and efficiency solutions

One of the downsides of power limitation is that it can slow down vessel operations by reducing the maximum sailing speed.

Wärtsilä offers a range of efficiency solutions that can be combined with its power limitation upgrades to minimise speed reduction while ensuring the vessel remains EEXI compliant.

“With our OEM expertise and holistic design approach we can optimise the overall solution design according to the operational profile of the vessel. As an added benefit, a solution that combines EPL and efficiency solutions also improves the vessel’s CII rating,” van der Heijden explains.

Wärtsilä’s energy efficiency solutions for mitigating speed loss after EPL include energy-efficiency technologies (EETs) suitable for all types of vessels. These have a direct impact on vessel propulsion efficiency by reducing hull resistance or improving propeller efficiency. Wärtsilä offers pre- and post-swirl devices such as Wärtsilä EnergoFlow and Wärtsilä EnergoProFin. Installing a replacement propeller that is optimised for the vessel’s current operational profile also offers significant potential benefits. Depending on the vessel type, energy savings in the region of 5–10% can be achieved by combining EETs with an optimised propeller.

In addition, Wärtsilä’s offering also includes solutions for hull air lubrication to reduce friction, wind-assisted propulsion solutions and the EcoControl smart control system for vessels with CPPs, which optimises the rpm and propeller pitch settings for maximum efficiency.

Closing the discussion on Wärtsilä’s solutions, participants were asked whether they had assessed the impact of power limitation on their business operations, with 29% saying they had already done so, 50% suggesting they were in the process of doing so and the remaining 21% saying they had not yet assessed the impact.

How is EPL applied in practice?

Taking over the discussion, Tim Cales, Senior Design Engineer, Hydrodynamics, Wärtsilä Marine Power, explains the practical steps vessel owners need to take when considering EPL as an option.

“The first step is to determine the size of the gap to compliance with an EEXI assessment, which sets the goals and involves gathering the data that an external third party will need to perform an official EEXI calculation, which is step two,” he explains. “For this calculation, classification societies will ask for all kinds of data including specific fuel oil consumption, sea-trial data and so on. This brings clarity in terms of the actual gap to compliance.”

Step three is to define the solution or a combination of solutions to address the gap, which is where Wärtsilä comes in as a trusted expert advisor. This is followed by solution engineering including drawings and documentation, and solution approval. “Here, we can support customers by preparing and submitting the documentation required by classification societies to allow them to formally assess the impact of the chosen solution package on the vessel’s EEXI performance,” Cales explains.

The final steps are to implement the solution package, have it verified onboard by a class surveyor and finally update the EEXI value of the vessel so the validity of its International Energy Efficiency Certificate can be extended.

Theoretical examples to demonstrate the implications of EPL

Cales continues by providing three example scenarios:

1. Compliance can be achieved through EPL with no operational restrictions

2. EPL causes severe operational restrictions, and

3. EPL conflicts somewhat with operational requirements

In example one we assume that the vessel needs to reduce its maximum continuous rating (MCR) down to 70% in order to be EEXI compliant, but is only operated up to 50% of its MCR, meaning there are no operational restrictions due to EPL. In this scenario speeds of 20 knots and above can no longer be achieved, but this has no negative impact on vessel operations since only speeds of 12–19 knots are frequently required. If the shipowner’s only goal is to achieve EEXI compliance Wärtsilä’s engine power limitation solution would allow them to achieve this.

In example two we assume that the vessel needs to reduce its MCR even further, down to 40%, in order to comply. The problem is the vessel is frequently operated at up to 70% of its MCR, meaning EPL would result in severe operational restrictions. In this scenario EPL would mean that speeds above 16 knots can no longer be achieved. There are no simple solutions in such a scenario, so alternative options are needed, such as fuel conversion to enable the use of low or zero-carbon fuels like LNG or ammonia. Other options include changing the operational profile of the vessel, or simply accepting that your vessel will have to slow down and employing additional capacity to make up the shortfall.

The cold, hard truth is that in some cases the most logical decision is to take the vessel out of operation permanently, either selling it or scrapping it. Another option is to avoid international trade altogether and operate only in domestic waters, since EEXI only applies to vessels engaged in international trade.

In example three we need a power limitation down to 80% of the vessel’s MCR, but the vessel is frequently operated up to 85% of its MCR, meaning there are some operational restrictions due to EPL. In this example EPL would mean that speeds above 14 knots can no longer be achieved. In this case there are a couple of pathways open to the vessel owner. One would be to combine EPL with energy-efficiency technologies, and another would be to install an in-line shaft generator.

For those considering EPL or ShaPoLi as an option, while the optimal path forward may appear complex and unclear, with an expert partner on your side and the right information at your fingertips identifying the right solution becomes far easier.

Learn more by watching the full webinar