When selecting an engine for your newbuild vessel, the options can quickly become overwhelming. Each manufacturer presents claims and data that seem compelling at first glance – but how do you cut through the noise and identify what really matters?

The simple secret is to look closely at the fine print of any information that an OEM publishes because manufacturers often present performance metrics differently. You need to decode the fine print and compare engines based on equivalent measures to make sure you’re comparing apples to apples. Here are just two examples of the difference that the fine print can make.

Making an engine look more efficient than it is

For the first example, let’s look at brake specific energy consumption (BSEC). BSEC is a measure of an engine's efficiency in converting fuel energy into useful work. It represents the amount of energy consumed to produce a unit of brake power (output power) over a specific time period.

A lower BSEC indicates better engine performance because it means that less energy is required to generate the same amount of power. This parameter is particularly useful when comparing engines operating on different fuels or under varying conditions as it provides a standardised way to evaluate energy efficiency.

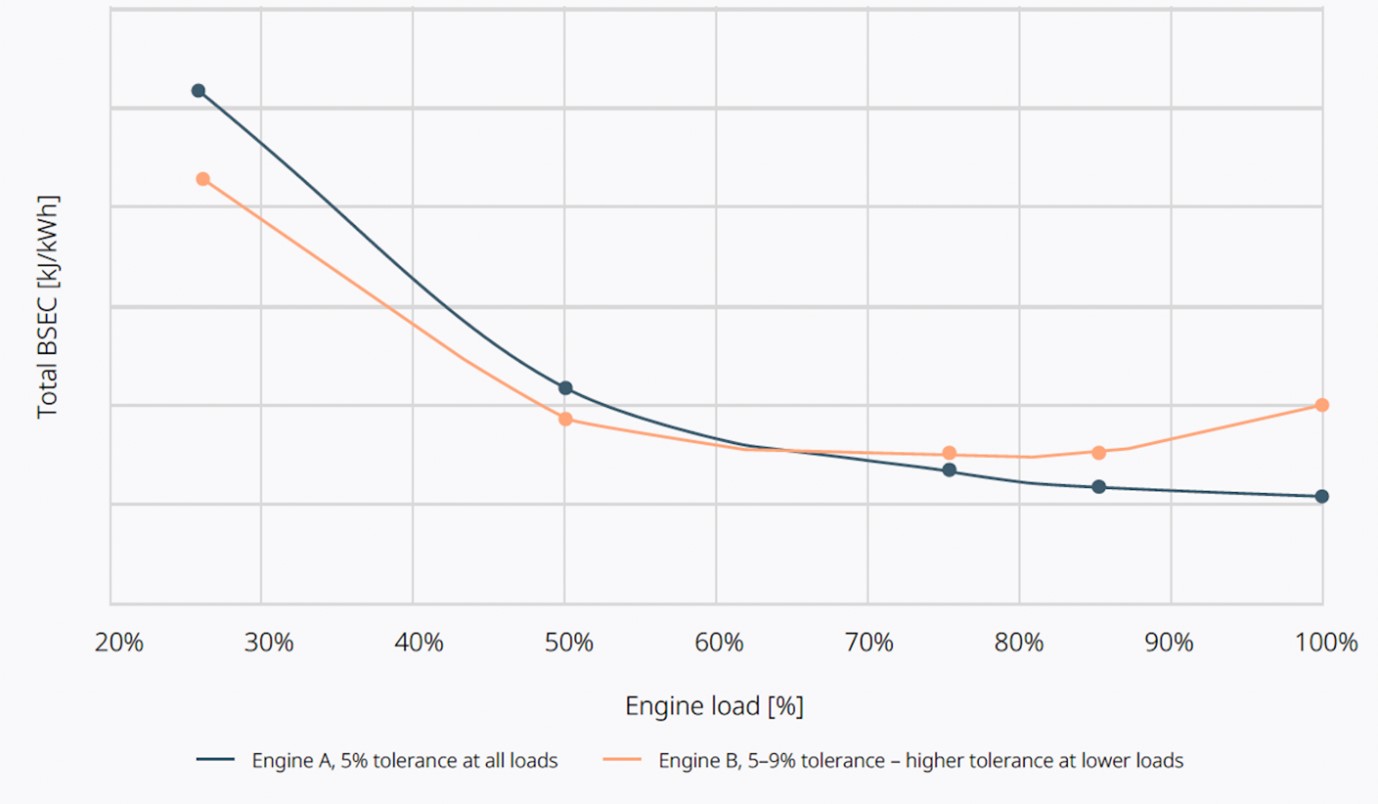

When evaluating the BSEC values of different engines, be sure to compare the value at the same load points and with the same tolerance, otherwise the results won’t be reliable. The table below shows what we mean:

In this case, engine B looks like the better choice for a vessel that operates at low loads. But if you look at the fine print, you’ll notice that engine B uses different tolerances from 5 to 9% across the range of loads, flattering the engine results and making it hard to know how the performance really compares with other engines.

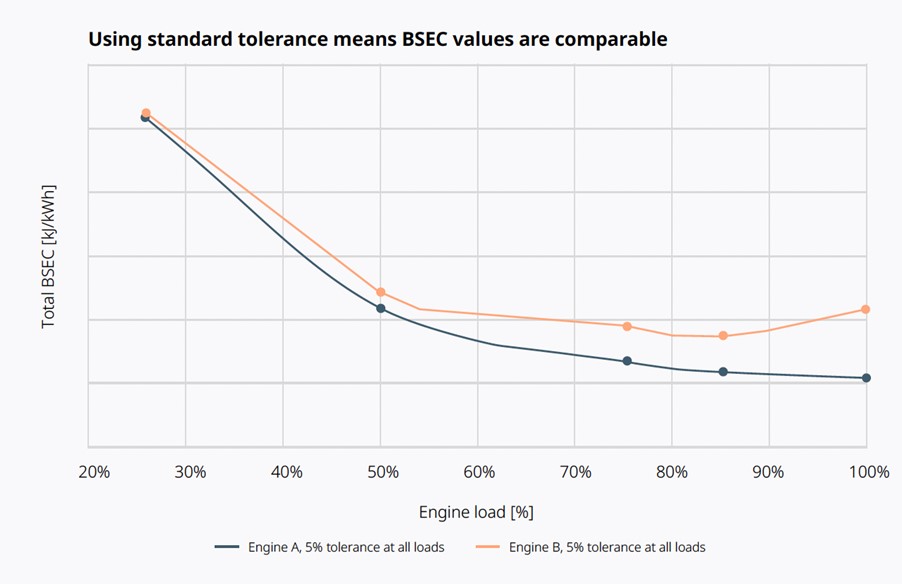

If a standard 5% tolerance is used across all loads for the same engines, the results look like this:

Suddenly, engine A is clearly the better choice when it comes to fuel use and therefore savings and emissions.

Making an engine’s fuel consumption look smaller

This is because Tier III requires lower engine emissions. To achieve this, a Tier III-compliant engine typically uses emission-control technologies such as a selective catalytic reduction (SCR) system.

Because SCR systems use fuel, they lower the overall fuel efficiency of the engine. Manufacturers sometimes don’t include the fuel consumption of accessories like SCR systems to make their engine’s fuel consumption figures look better.

Why does the fine print matter for marine engine performance?

What these two examples show is that an engine can be made to look more efficient and to consume less fuel than it actually does. Highlighting performance at optimal tolerances can make an engine look more efficient than its competitors; not including the fuel consumption of an accessory will falsely improve fuel consumption data. But by reading the fine print, you’ll be able to see if an OEM is using tricks like this – and be able to make an informed decision when comparing alternative marine engines.

How your engine choice affects a vessel over its lifetime

But why does this even matter? The answer is that choosing an engine is a long-term investment – and the consequences of a less-than-optimal decision can affect your vessel’s operational efficiency, costs and compliance for years to come.

Focusing solely on upfront capital expenses (CAPEX) might seem tempting, but it’s a shortsighted approach. Operational expenses (OPEX) over a vessel’s lifecycle often far outweigh the upfront costs, especially if your engine struggles to meet evolving regulatory demands or incurs higher maintenance costs.

Choosing the right engine can help you in several ways, including:

- saving fuel and money

- lowering emissions

- making environmental compliance easier

- simplifying maintenance

- increasing operational flexibility

- future-proofing your vessel with a solution that can be converted to run on fuels like green methanol or hydrogen

Looking for more advice on how to choose the right engine for your newbuild vessel? Get all the tips you need in our handy guide, An insider’s guide to ship engines: 11 tips that help you make the best choice.

The insider knowledge in this guide will help you avoid potentially costly mistakes. When you know what questions to ask and what details to look out for, you’ll be able to compare options confidently and choose an engine that performs to your expectations, is compliant with evolving regulations and remains cost-effective for years to come.

This article on smart ways to choose a ship engine first appeared as one of Wärtsilä’s Insights stories.