The trend of expanding coastal populations worldwide is leading to a growing reliance on high-speed vessels for public transportation and other purposes. The exciting opportunities this creates, along with an increased focus on reducing emissions, are driving new “smarter” technologies that can deliver cost-effective and efficient solutions alongside innovations in sustainability. As well as being quick, simple and cost-efficient to install, Wärtsilä midsize waterjets minimise maintenance requirements and enhance sustainability for operators of high-speed workboats, yachts, passenger vessels, patrol boats and other shallow-draft vessels seeking reliability alongside robustness and high performance.

Improving efficiency and reducing operating costs

Wärtsilä’s unique midsize waterjets are designed for fast vessels with a minimum length of approximately 30 metres and an engine power range of 1,000-4,500 kW, opening the benefits of waterjets up to operators of these vessels. The waterjets offer superior efficiency for speeds over 25 knots when compared with other propulsion methods and reduce the risk of grounding or damaging the propulsion system in shallow-draft vessels. They also provide better manoeuvrability than CPP and FPP propellers due to the integrated steering and reversing system with quick response time. In addition, waterjets reduce noise and vibration levels, making passenger journeys more comfortable.

Operators benefit from low lifetime costs, with the inboard location of the hydraulics reducing maintenance requirements and providing ease of access to remove the need for dry docking. Some elements of the construction use aluminium, which reduces the unit’s weight and lowers the price, while stainless steel is used for any parts that will be subjected to more demanding conditions to ensure durability and high performance throughout the vessel’s lifecycle. The water-lubricated bearing also eliminates oil leakage and has no external oil-containing parts, which is widely recognised as the most environmentally friendly bearing solution for operators sailing closer to shore or in restricted environments.

Digital technology optimises performance

Wärtsilä midsize waterjets make use of the Wärtsilä Data Collection Unit (WDCU), which collects real-time data from the jets as well as a broad range of sensors installed onboard (including on third-party equipment). WDCU helps optimise the operability, engine fuel economy and periodic maintenance of the waterjets by providing information such as RPM, steering angles, thrust bearing temperature and pressure availability of the power pack. This data is stored safely, both locally and in the cloud, with rigorous cyber security measures in place, giving operators access to dashboards with real-time information and historic trend data that shows the situation onboard over time. When used in combination with remote monitoring and Wärtsilä’s cloud-based services, this enables optimisation at vessel and fleet level by reducing operating costs and increasing vessel availability. The WDCU also alerts operators if the data goes outside of normal parameters.

As part of its Smart Marine Ecosystem vision, Wärtsilä is committed to leading the industry towards a decarbonised and sustainable future by delivering reliability, safety and environmentally sound performance through a portfolio of medium and high-speed engines, propulsion and waterjet systems, hybrid technology and integrated powertrain systems. The SmartMove suite provides a fully integrated solution encompassing midsize waterjets to assist crew with challenging manoeuvres through dynamic positioning and automated capabilities, enabling autonomous harbour entering, docking and quay-to-quay transit. These smart technologies save captains and their crews effort by allowing them to carry out repeat operations perfectly every time, while also reducing operating costs, minimising wastage and ensuring predictability, efficiency and safety.

Reducing installation time and supporting sustainable operations

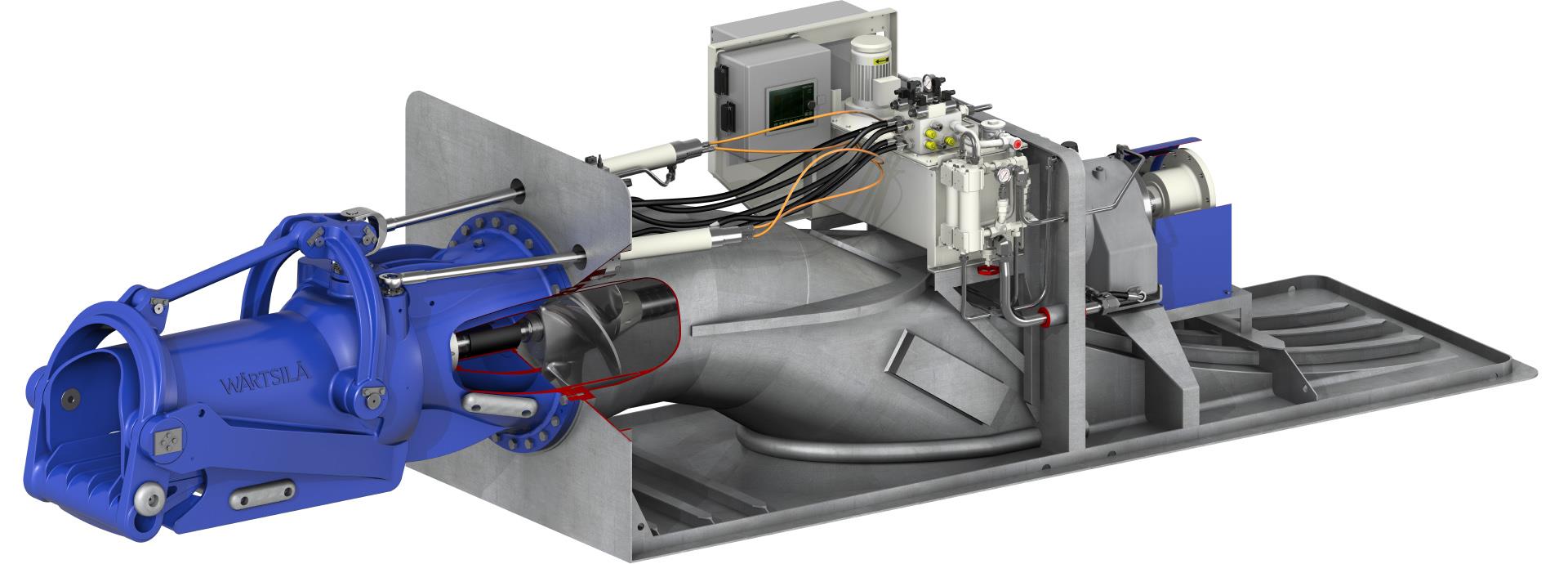

Wärtsilä midsize waterjets have been developed with ease of installation in mind, and they are the most complete waterjet package currently on the market. The product comes fully mounted on a preassembled skid complete with intake, compact steering and reversing unit, hydraulics and thrust bearing. Piping work is already completed and the shaft line is aligned, meaning the unit can be simply welded or bolted into the hull construction with no shaft assembly, yard oil piping or oil flushing required. This results in a risk-free plug-and-play installation that saves up to 80% on installation times – also reducing costs in the process – and can be carried out at smaller shipyards and on hulls made from different materials.

The lightweight and compact waterjets offer high levels of reliability and sustainability, with extensive redundancy built into the system to ensure that operations can continue as smoothly as possible should issues arise. This includes a backup seal, backup hydraulics to provide pressure for steering the vessel in the event of PTO (power take-off) failure and a spare PTO belt for easy replacement. In addition, Wärtsilä’s extensive network of service engineers and distributors ensures quicker response times, helping operators reduce downtime and keep their vessels running.

“Our waterjet customers and operators around the globe are looking for a high-quality and reliable solution, while shipbuilders come to us for ease of integration and competitive pricing – our midsize waterjets meet these and many other needs,” states David van Luijtelaar, Global Sales Manager at Wärtsilä.

Get in touch with David to find out more about Wärtsilä’s unique midsize waterjet technology and find out how you can access it, or for navy waterjet applications, contact Jeroen Vedder, Global Sales Manager Navy & Waterjets.