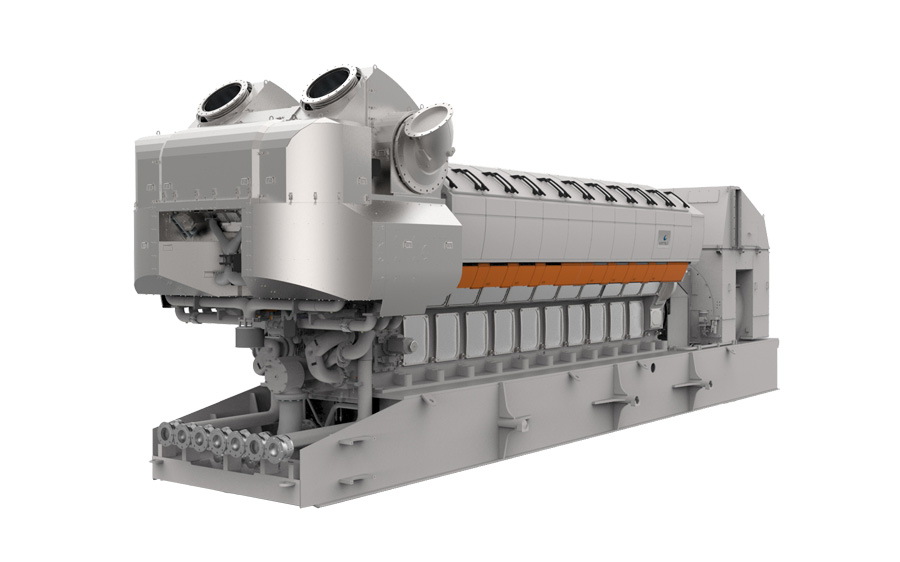

Wärtsilä 31SG gas engine

The most efficient gas engine, Wärtsilä 31SG, is a four-stroke, spark-ignited, lean-burn gas engine generating set. With its world-class open-cycle efficiency and unparalleled dynamic capabilities, it reduces environmental footprint and lowers the total cost of ownership.

Wärtsilä 31SG is well suited for baseload production, balancing renewables and industrial applications where reducing carbon emissions while producing reliable power is crucial. Its capability of fast starting and stopping and ability to run on sustainable fuels secures low emissions and high efficiency. It also meets the specific needs of combined heat and power (CHP) plants, for example steam generation, hot or chilled water or a combination of the above. Wärtsilä engine power plants can be delivered both as EPC and Equipment Delivery contracts.

Key benefits of the Wärtsilä 31SG gas engine

- World-class open-cycle efficiency enabled by 2-stage turbocharging system

- Synchronises with the grid within 30 seconds from start command

- Adaptability for various gas qualities

- Capable of hydrogen blending

- Excellent load following capabilities

- Cost efficient maintenance

Customer stories

Our proudest numbers

Power to grid

Electrical efficiency

Electrical power

Technical data of the Wärtsilä 31SG gas engine

| Wärtsilä 31SG gas engine generating set | |||

| Cylinder configurations | 20 V | ||

| Cylinder bore | 310 mm | ||

| Piston stroke | 430 mm | ||

| Engine speed | 750 rpm (50 Hz), 720 rpm (60 Hz) | ||

| Performance * | |||

| WÄRTSILÄ 31SG | WÄRTSILÄ 31SG Efficiency optimised | WÄRTSILÄ 31SG Power optimised | |

| Rated electrical power (kW) | 11 777 (50 Hz) 11 377 (60 Hz) | 10 790 (50 Hz) 10 389 (60 Hz) | 12 762 (50Hz) 12 372 (60Hz) |

| Electrical efficiency (%) | 51.5 (50 Hz) 51.6 (60 Hz) | 52.0 (50 Hz) 52.1 (60 Hz) | 50.2 (50 Hz) 50.4 (60 Hz) |

| Heat rate kJ/kWh | 6 986 (50 Hz) 6 971 (60 Hz) | 6 922 (50 Hz) 6 907 (60 H) | 7 165 (50 Hz) 7 142 (60 H) |

| Loading and unloading | |||

| Connected to grid | Full load | ||

| Regular start time (min:sec) | 00:30 | < 5 | |

| Fast start time (min:sec) | 00:30 | < 2 | |

| Stop time (min) | < 2 | ||

| Ramp rate (hot, load/min) | > 100% | ||

| Minimum Load | |||

| Unit level | 10% | ||

| Plant level | 1% | ||

| * Rated electrical power and electrical efficiencies are given at generator terminals at 100kPa ambient pressure, 25°C suction air temperature and 30% relative humidity, and without engine driven pumps. Power factor 1.0 (site). Electrical efficiency and heat rate with 5% tolerance. Site conditions, fuel and applicable emission limits may have an impact on performance figures. Please contact Wärtsilä for project-specific performance data. Emission figures for LBF must be evaluated case by case. Catalyst systems are designed based on project specific requirements. Certain fuel components are poisonous for catalyst elements. Maximum amount of these components to be limited in the fuel in applications where catalyst system is installed. |

| Disclaimer: The information contained herein is provided for informational purposes only and may not be incorporated, in whole or in part, into any agreement or proposal. No representation of any kind is made in respect of any information contained herein and Wärtsilä expressly disclaims any responsibility for, and does not guarantee, the correctness or the completeness of the information. The calculations and assumptions included in the information do not necessarily take into account all the factors that could be relevant in a particular case. Information herein shall not be construed as a guarantee or warranty of the performance of any Wärtsilä technology, equipment or installation. |

Would you like to know more?

Contact us

Fill in a contact form and our experts aim to be in contact within 1-2 business days. Contact us »

Read our leaflet

Read our product brochure to get all the details. Download leaflet »