Combined power generation and heat recovery power plant

Wärtsilä’s combined power generation and heat recovery plant offering comprises solutions for combined heat and power (CHP) including dynamic district heating (DDH), district cooling and power (DCAP) and trigeneration for applications that require both heating and cooling.

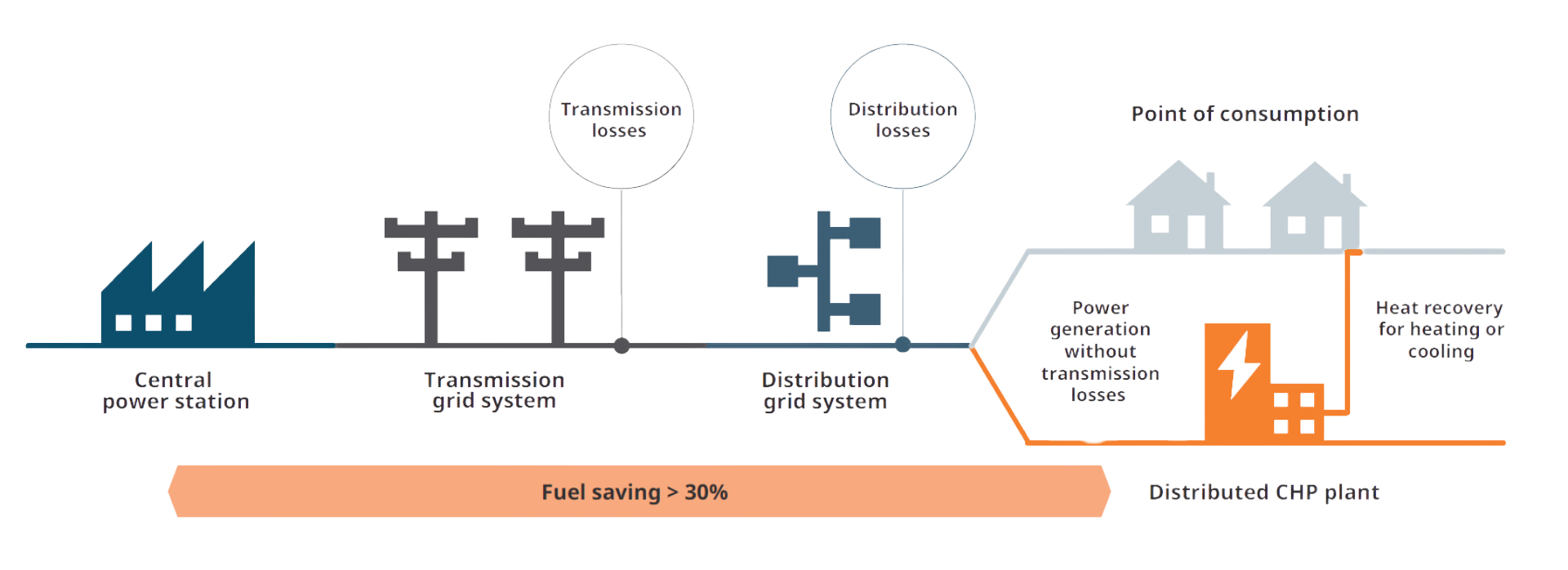

These fuel-efficient plants help to reduce carbon emissions and increase profitability by using waste heat streams from reciprocating internal combustion engines. Wärtsilä’s solutions enable power, heat and cooling generation closer to consumers, significantly reducing transmission and distribution losses.

The modular design of Wärtsilä CHP plants ensures efficiency over a wide load range and enables on-site maintenance without production downtime. Plants can be complemented with Wärtsilä lifecycle solutions to ensure optimal efficiency and performance throughout their lifetime.

Key benefits of Wärtsilä heat recovery power plants

Cost efficient operation with a small CO2 footprint.

- Distributed electrical and thermal power production close to consumers, reducing transmission losses and distribution times.

- High efficiency compared to separate power and heat generation.

- Multi-unit design maintains efficiency across a wide load range.

Quick reaction to electricity price variations and changes in power, heating and cooling demands.

- Flexible operation with multiple units and fast startup and ramp-up rates.

- Flexibility can be further improved with heat storage.

Reliable power available at all times.

- Lifecycle solutions ensure optimal efficiency and performance throughout the plant lifecycle.

- Multi-unit design enables on-site maintenance without production downtime.

Tailored heat recovery

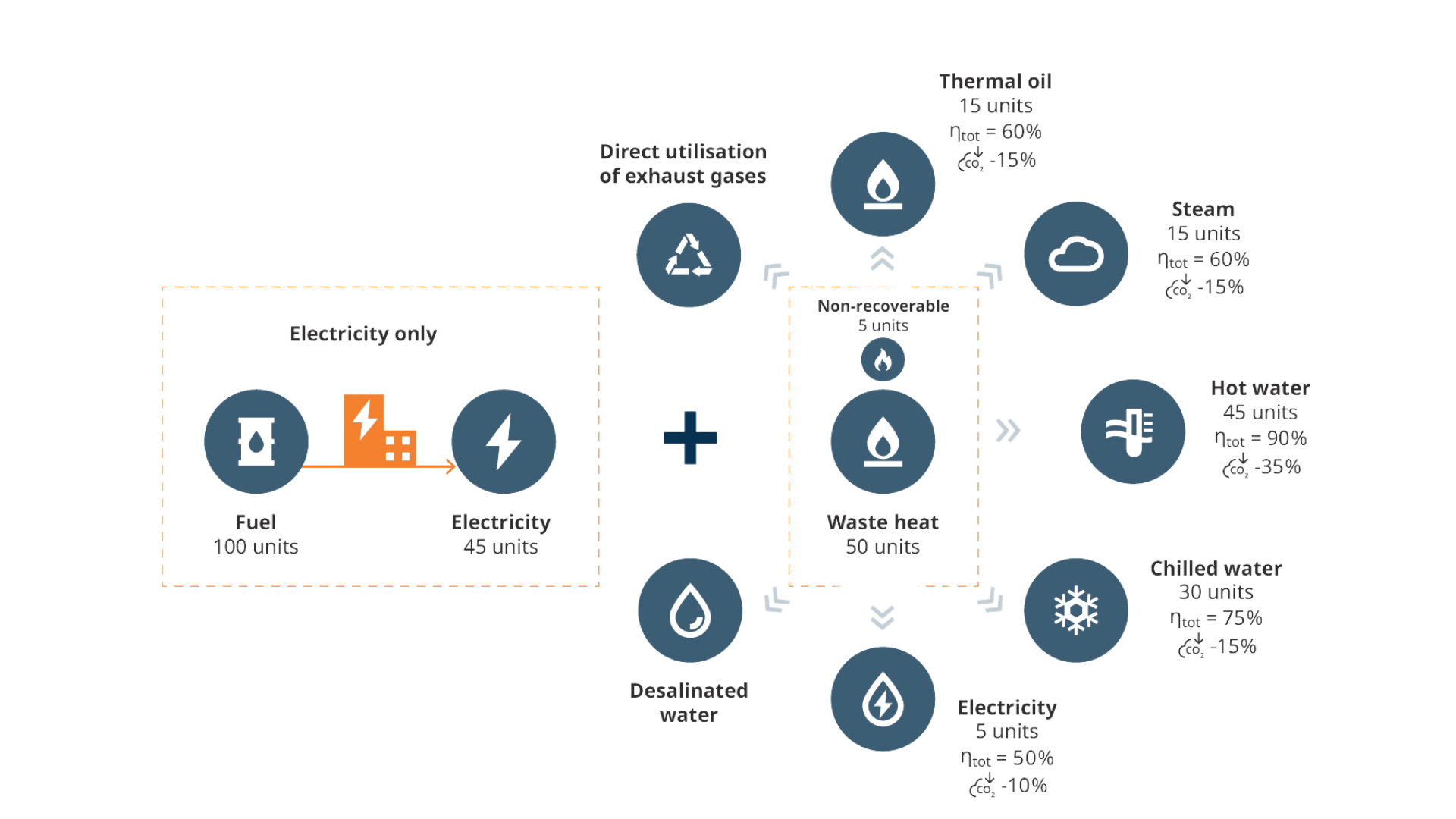

Heat recovery products can be hot water, steam, thermal oil, chilled water or even a combination of these. Each heat recovery system is tailored according to your specific needs and does not affect the electrical output or the electrical efficiency of the engine.

Generating electrical and thermal power close to where it is consumed reduces transmission and distribution losses. This approach can cut fuel consumption by more than 30% compared to centralised power production with long transmission distances.

The heat recovery power plant can be built over two floors to save space, with the generating set and auxiliaries on the ground floor and the ventilation, exhaust gas heat recovery and emission reduction equipment on the second floor.

The modular plant concept provides high plant efficiency at all loads. During periods of low demand, selected gensets can be powered down for maintenance or to save fuel, while the plant continues to run at peak efficiency.

During peak demand periods the plant can quickly ramp-up to 100% electrical output in just two minutes, making it ideal for complementing power production from renewable sources like wind and solar.

Energy-efficient CHP solutions for industry and homes

A Wärtsilä CHP plant can achieve over 90% efficiency, with the most common heat products being hot water and steam. This makes it ideal for both industrial and district heating applications. The automation system controls all internal processes and is fully integrated with all the necessary signals and connections to guarantee compatibility with external systems.

Process steam for industrial applications can be generated with engine exhaust energy, with or without additional hot water recovery from the engine cooling circuits.

Combined heat and power solutions for various needs

Download the brochure

Read more about flexible power generation combined with heat recovery.

Our heat recovery power plant products

References

Would you like to know more?

Contact us

Fill in a contact form and our experts aim to be in contact within 1-2 business days. Contact us »