Wärtsilä OPTI-DPtm Engagement Tool - Delivering high performance station keeping

Vessels that require efficient and safe dynamic positioning (DP) are also becoming larger, more complex. This requires DP of the highest calibre designed for the vessel and its’ operating profile.

To calculate the configuration and power requirements for a specific vessel in a variety of conditions requires a huge amount of experience and knowledge in CFD and hydrodynamics and used to take days to get the results.

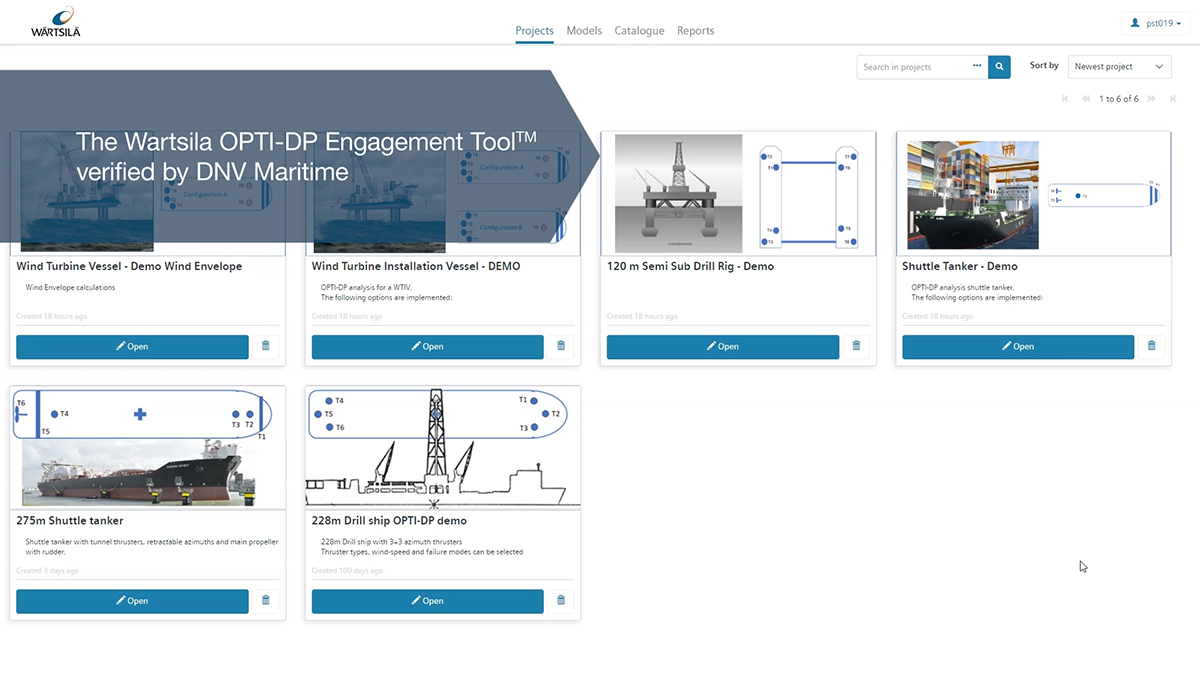

However, we have developed the Wärtsilä OPTI-DPtm Engagement Tool which is verified by DNV Maritime and takes all the calculations and data and allows multiple configurations to be modelled to ensure that the most efficient and safe thruster configuration can be achieved to deliver the thrust required for high performance dynamic positioning – whatever the environment, vessel or missions required.

A Focus on DP Performance

Conventional methods of configuring and modelling thrusters for complex vessels are limited when it comes to accurate DP performance calculations. The OPTI-DP Engagement Tool solves this problem by offering full flexibility in prescribing the environmental operating conditions, with independent wind, wave and current directions, if desired, plus the ability to simulate failure.

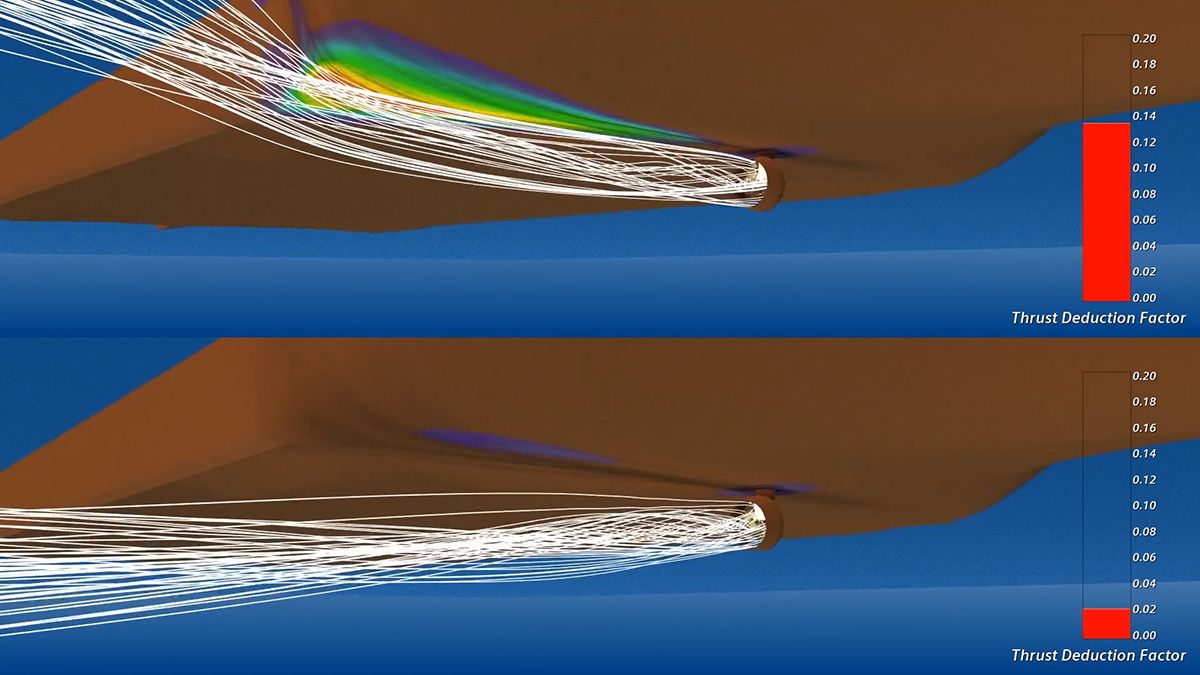

Hull interaction analysis for 8 degree tilted thruster

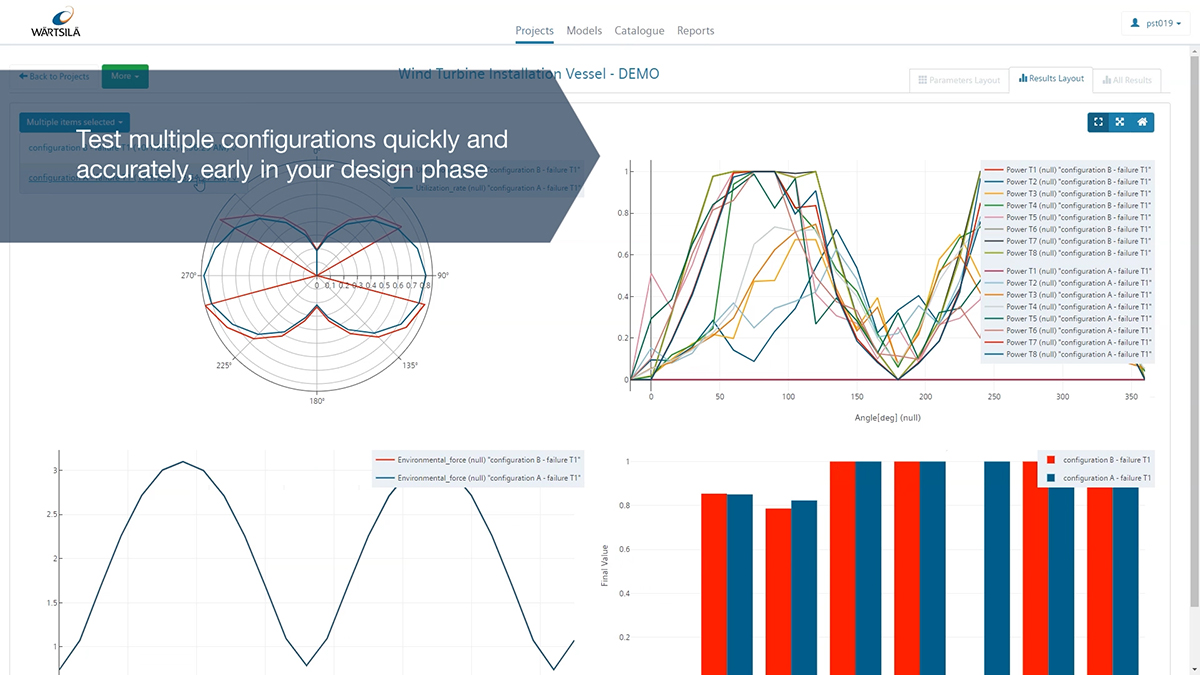

Polar plots and thrust analysis

Multiple vessel configuration

KEY BENEFITS

- Early configuration at the design phase to allow integrated design

- Optimal thruster and system configuration for efficient and safe DP

- Accurate DP power requirements to determine power plant requirements

- Reduces CAPEX and OPEX through vessel efficiency, a higher DP window and optimal equipment selection

- Digital tool accessible live with Wartsila experts

- Quick results – results available in hours or minutes instead of weeks

In the offshore industry, there is a trend towards larger, more complex vessels that operate further from shore in deeper waters with rougher seas. Wärtsilä offers a range of innovative solutions that help to ensure safe and efficient dynamic positioning (DP) operations in these demanding conditions. To calculate the configuration and power requirements for a specific vessel in a variety of conditions requires a huge amount of experience and knowledge in CFD and hydrodynamics. We have now made this accessible through the OPTI-DP Engagement Tool. The tool takes all the calculations and data and allows multiple configurations to be modelled to ensure that the most efficient and safe thruster configuration can be achieved to deliver the thrust required for high performance dynamic positioning.

The new tool takes all details of thruster performance into account and utilises detailed computational fluid dynamics (CFD) to deliver accurate results. The tool implements actual 8-degree tilted azimuth thruster performance over a 360-degree circumference in the thrust allocation logic (TAL). It also allows an unlimited number of forbidden zones to avoid unwanted thruster to thruster interaction and minimise the negative impact of thruster interaction with other structural areas such as jackup legs.

With the OPTI-DP Engagement Tool we can simplify power consumption per thruster based on the specific vessel single line diagram (SLD). Performance evaluation for different failure modes is part of the standard vessel DP capability evaluation, and results are presented in thrust-utilisation polar plots for given environmental conditions or maximum acceptable windspeed plots. In a nutshell, this innovative tool allows an owner or designer to see thruster solutions in the early design phase to allow changes to be made to achieve the best outcome.

With the OPTI-DP Engagement Tool, we can communicate vessel DP performance in clear polar plots and diagrams that make it simple to compare, evaluate and make decisions.

OPTI-DP Engagement tool key features

- Thruster performance is based on full-scale CFD simulations

- Environmental forces are 100% in line with DNV-GL L1 methodology (for monohulls)

- Allows full flexibility to specify a range of environmental conditions by simulating wind, waves, current and additional forces (such as riser drag)

- Allows implementation of azimuth thrusters, tunnel thrusters and propeller-rudder combinations

- Implements thruster-hull interaction losses in a 360° circumference (other tools use a single constant value)

- Allows an unlimited number of forbidden zones for thruster interaction and riser interference

- Enables performance degradation due to current effects

- Allows the simulation of failure cases

- All of these combined allow the optimisation of the system configuration