Cavitation tunnel

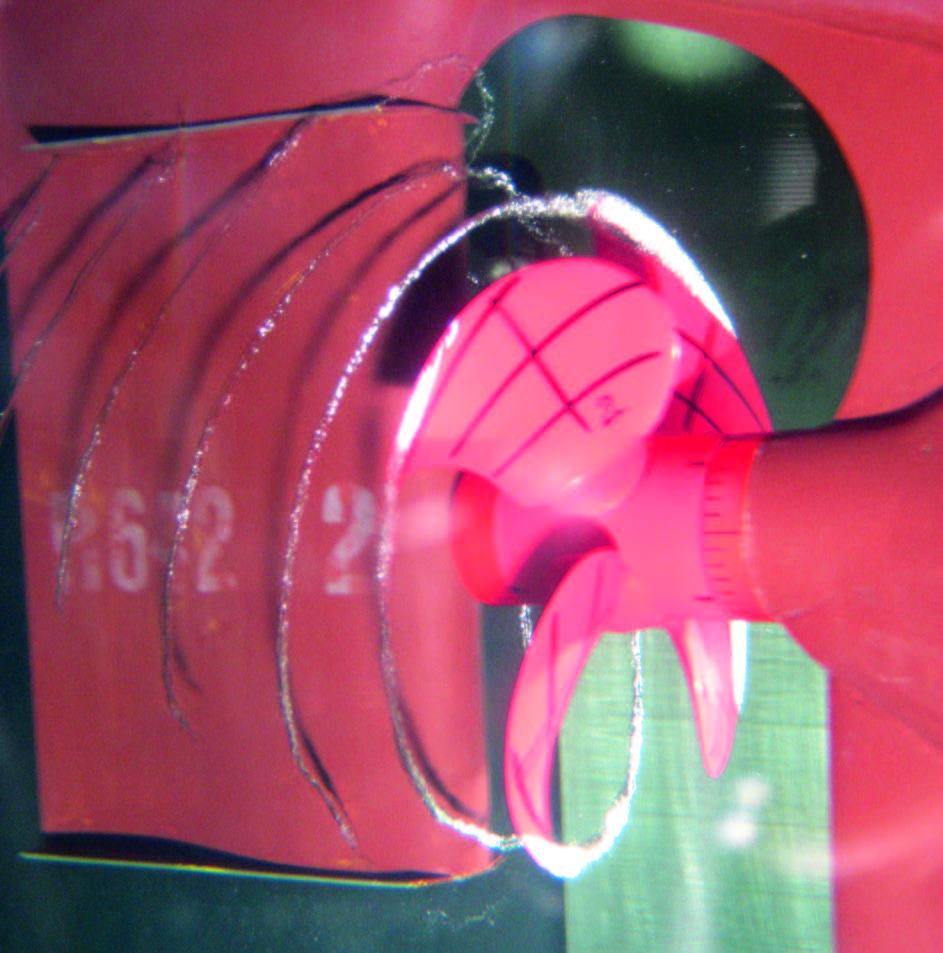

A facility used for propeller cavitation tests. This is a vertical water circuit with large diameter pipes. A parallel inflow is established. With or without a ship model, the propeller, attached to a dynamometer, is brought into the flow, and its thrust and torque is measured at different ratios of propeller speed to inflow velocity. To ensure similarity to the full-scale propeller the pressure in the tunnel is lowered to produce the correctcavitation number at the propeller axis.

Cavitation tunnels are equipped with stroboscopic lights that illuminate the propeller intermittently. Propeller blades are always seen at the same position and the eye perceives the propeller and cavitation patterns on each blade as stationary. See alsoHYKAT.

Extremely large cavitation tunnels were built in France, the United States and in Germany to reduce the consequences of scale effects. Models (ships, submarines, torpedoes, etc.) are tested with the complete hull-propulsion appendage as an integrated unit, and tests are carried out at high Reynolds numbers, that is with high velocities.