A sawmill is established in Värtsilä, a small village in Northern Karelia on April 12, 1834. The sawmill rapidly expands into an iron works company.

Historical photo of the sawmill.

Company president Wilhelm Wahlforss starts developing Wärtsilä into a multi-sector company by acquiring major Finnish shipyards and companies. This marked our entry into the marine industry that later becomes a core market for us.

The threat of war encourages Wilhelm to purchase many domestic engineering works that manufacture, for example ammunition and paper machines.

Wärtsilä's headquarters move from Karelia to Helsinki, Finland.

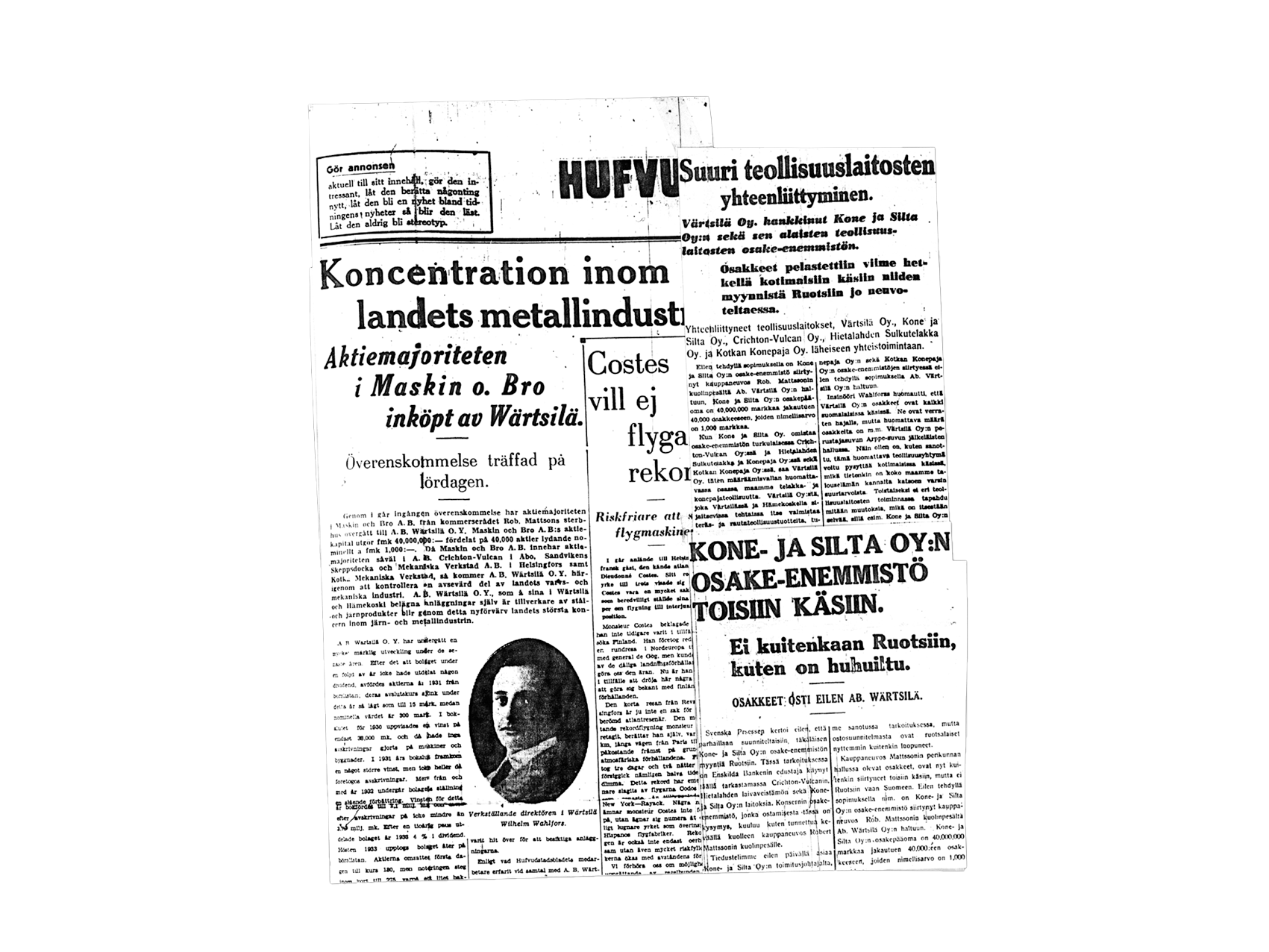

Newspaper articles about Wärtsilä acquiring a majority holding in Kone- ja Siltarakennus Oy in 1935.

Wärtsilä's diesel engine era begins as we sign a licence agreement with Friedrich Krupp Germania Werft AG in Germany. The first engines under the licence are delivered in 1940.

Wärtsilä's previous acquisitions prove useful during World War II. As Finland needs to pay war reparations to Russia, Wärtsilä becomes the biggest provider of the items.

Wärtsilä becomes the biggest industrial company in Finland with over 11,000 employees.

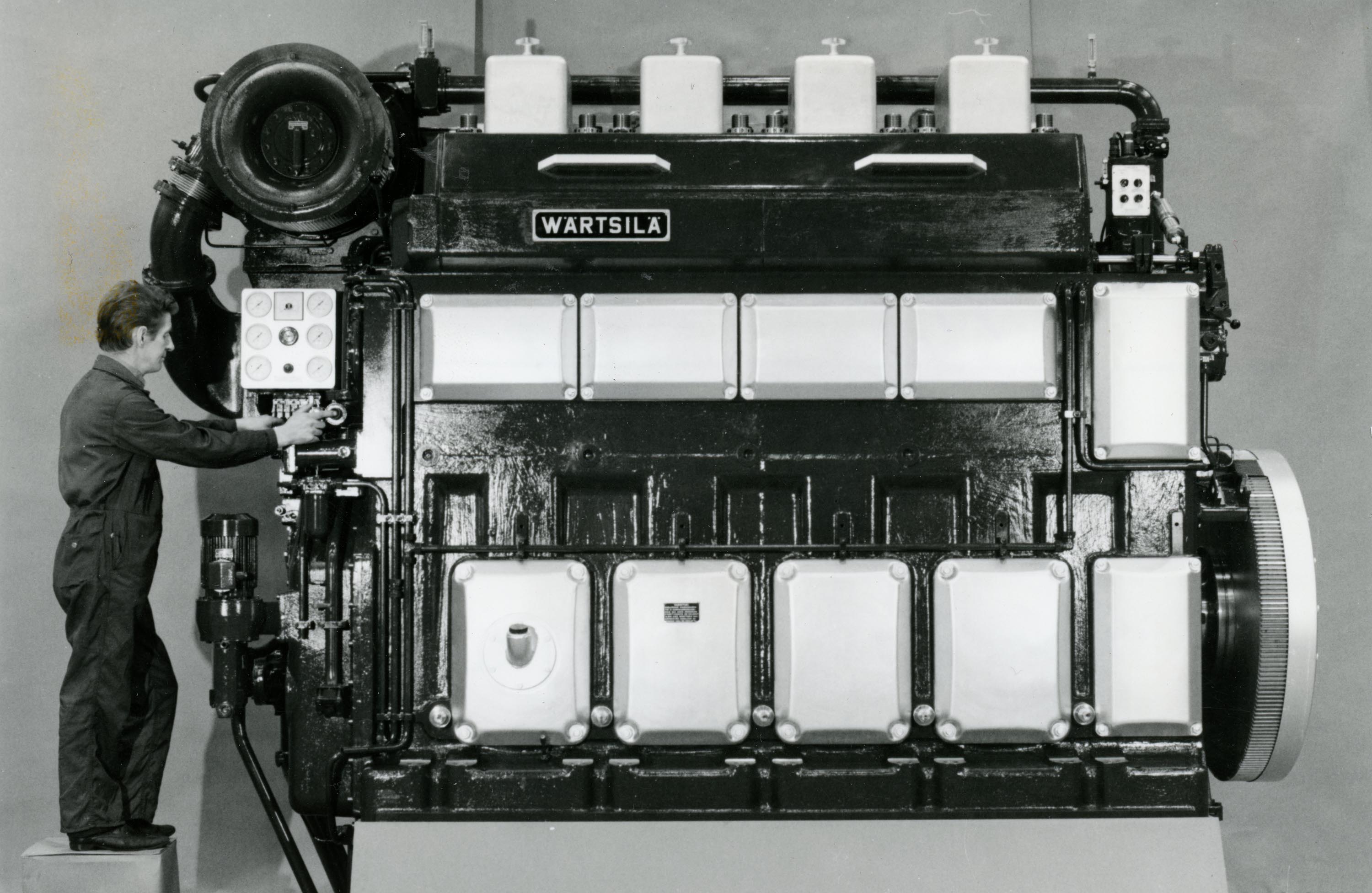

Wärtsilä makes the decision to start designing our own diesel engines. Wilmer Wahlstedt, a young civil engineer, is called to Vaasa to lead the work.

Story: The birth of the first Wärtsilä diesel engine

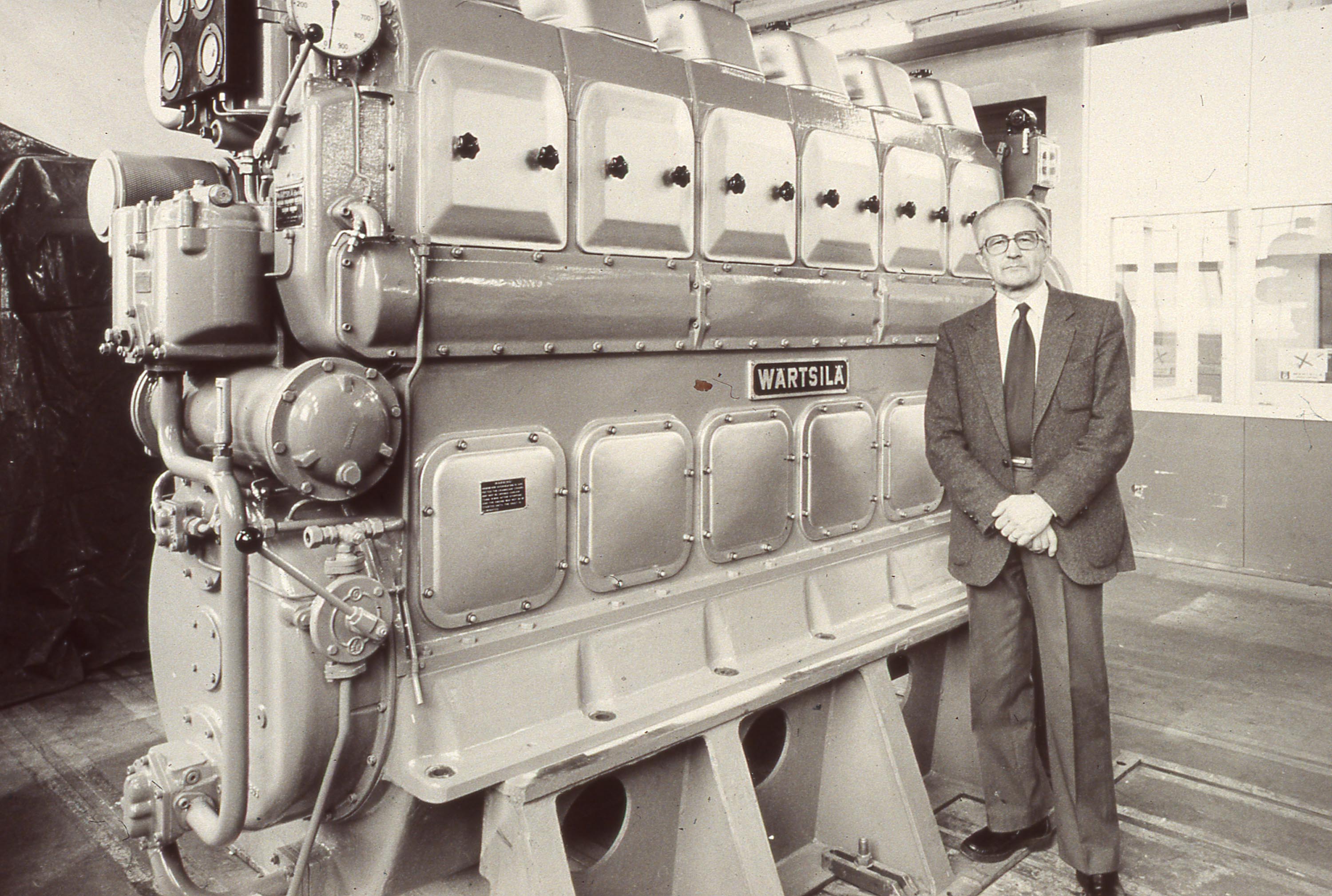

Wilmer Wahlstedt posing next to the first Wärtsilä Vasa 614.

The first Wärtsilä-designed diesel engine, the Wärtsilä Vasa 14, is started for the first time.

The first commercial engines, the Wärtsilä Vasa 614 with six cylinders, are delivered to a car ferry sailing between Finland and Sweden.

Wärtsilä enters the energy industry. With some modifications to our engine a separate line for power plants is created and we sign our first energy deal in 1973 in Tanzania. Meanwhile, the research on future fuels intensifies and Wärtsilä launches the first-ever 4-stroke engine operating on heavy fuel oil.

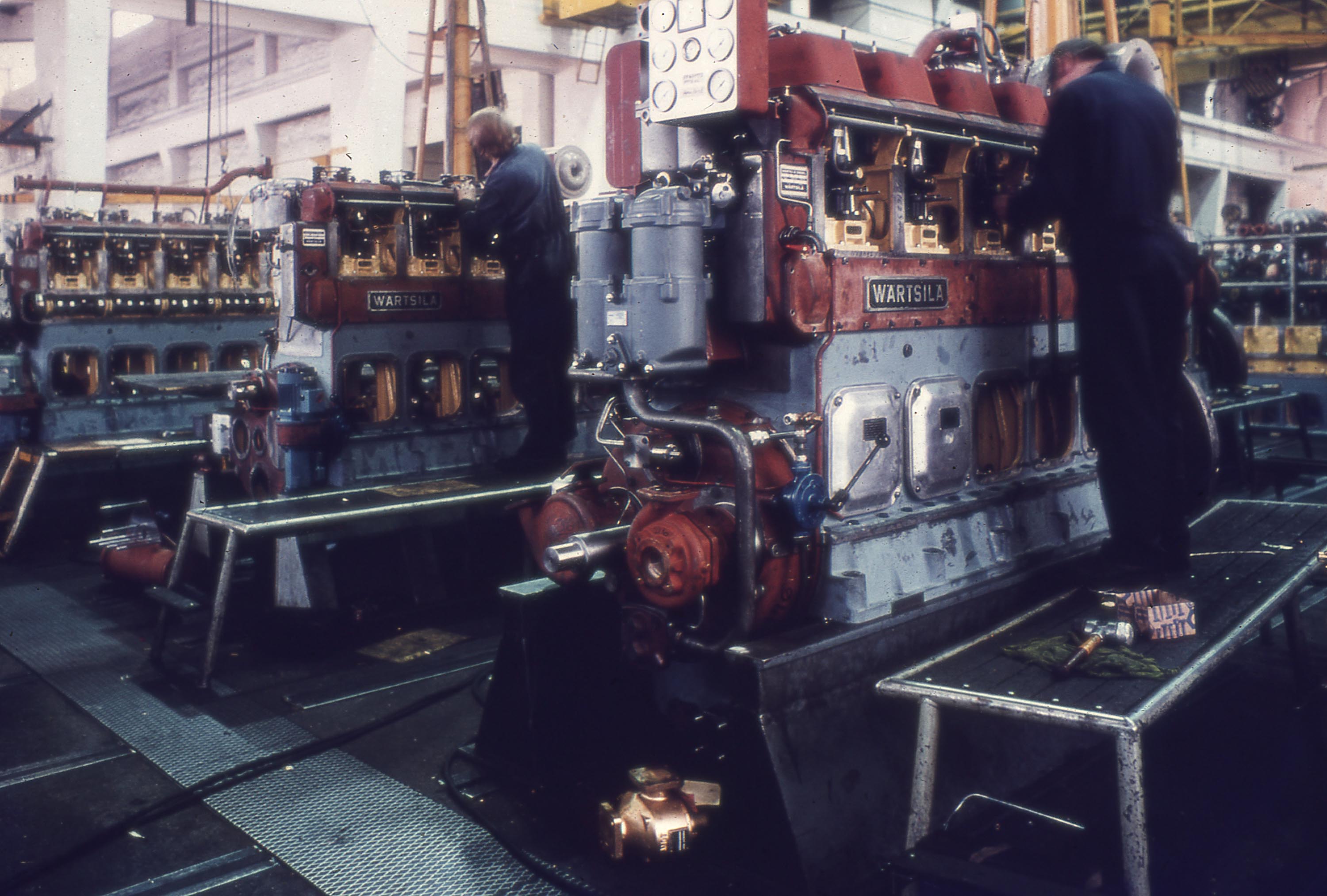

Factory workers at Wärtsilä.

In our Vaasa laboratory, a major marine industry milestone is reached as our diesel engine can now run on inexpensive heavy fuel.

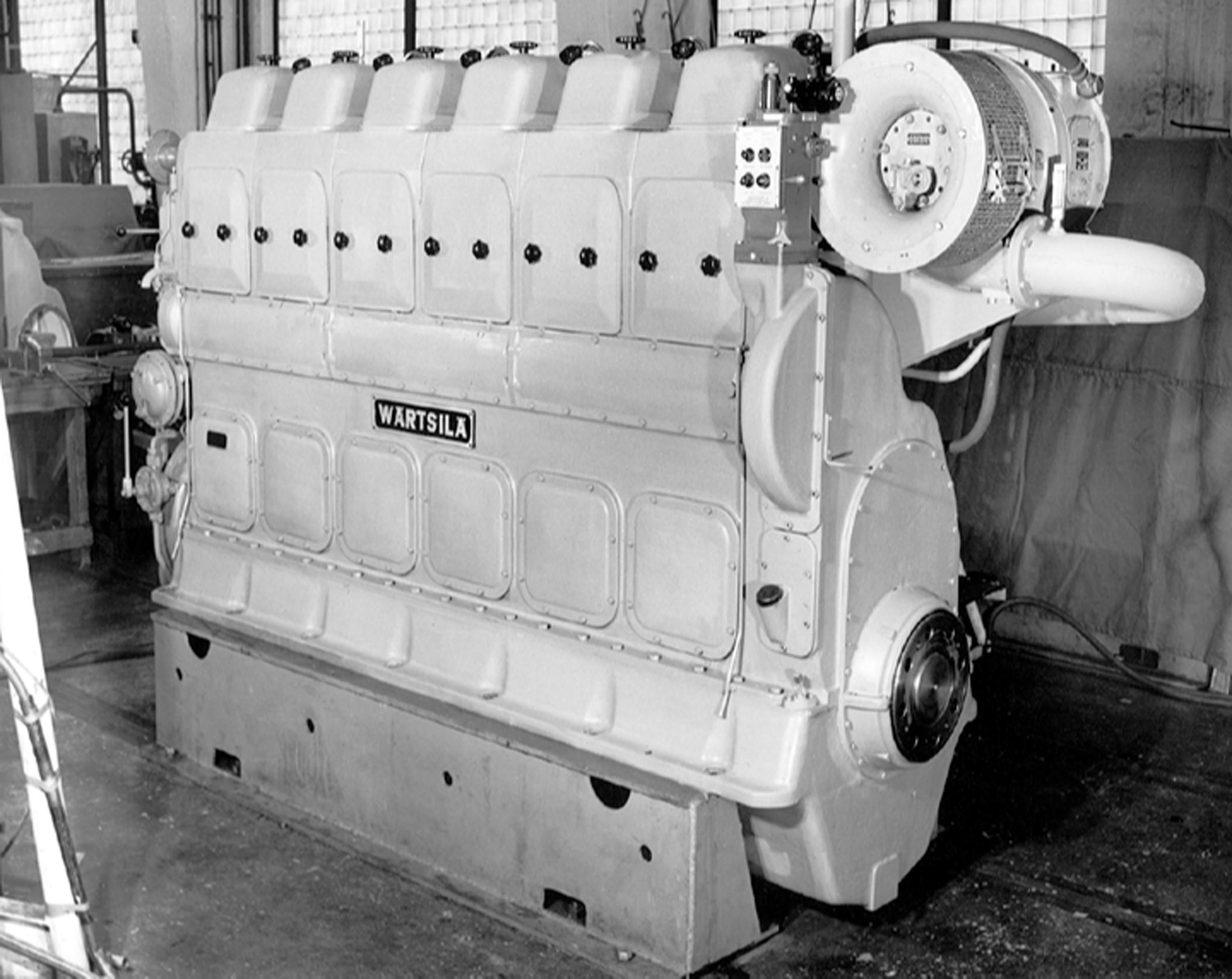

The Wärtsilä Vasa 32 started production in 1976.

Wärtsilä invests further in diesel engine technology, and our manufacturing operations go international as we acquire Swedish NOHAB diesel business.

Story: The day the flywheel broke in halfThe long crisis in the global marine industry leads Wärtsilä to withdraw from the ship building industry. Reorganisations in the company strengthen Wärtsilä's focus on power supply for marine and energy and some of our smaller businesses are divested.

Story: The focus remains on people Story: Chaika – A mighty Soviet beautyWärtsilä supplies the propulsion to the marine research vessel RSS James Clark Ross. The vessel, which was launched in December 1990 by HM Queen Elizabeth II, was one of the most advanced polar research vessels of its time.

After a decade of developing dual-fuel (DF) technology, we introduce our breakthrough DF engine.

Story: Do they sell toilets here?Our engine portfolio grows to slow-speed engines as we acquire New Sulzer Diesel. This makes us a global leader in the ship engine business.

Story: Surrounded by civil war and under curfew: Yes we can!

Wärtsilä acquires several component providers which makes us capable of delivering the entire marine engine system: both the engine and power transmitting systems.

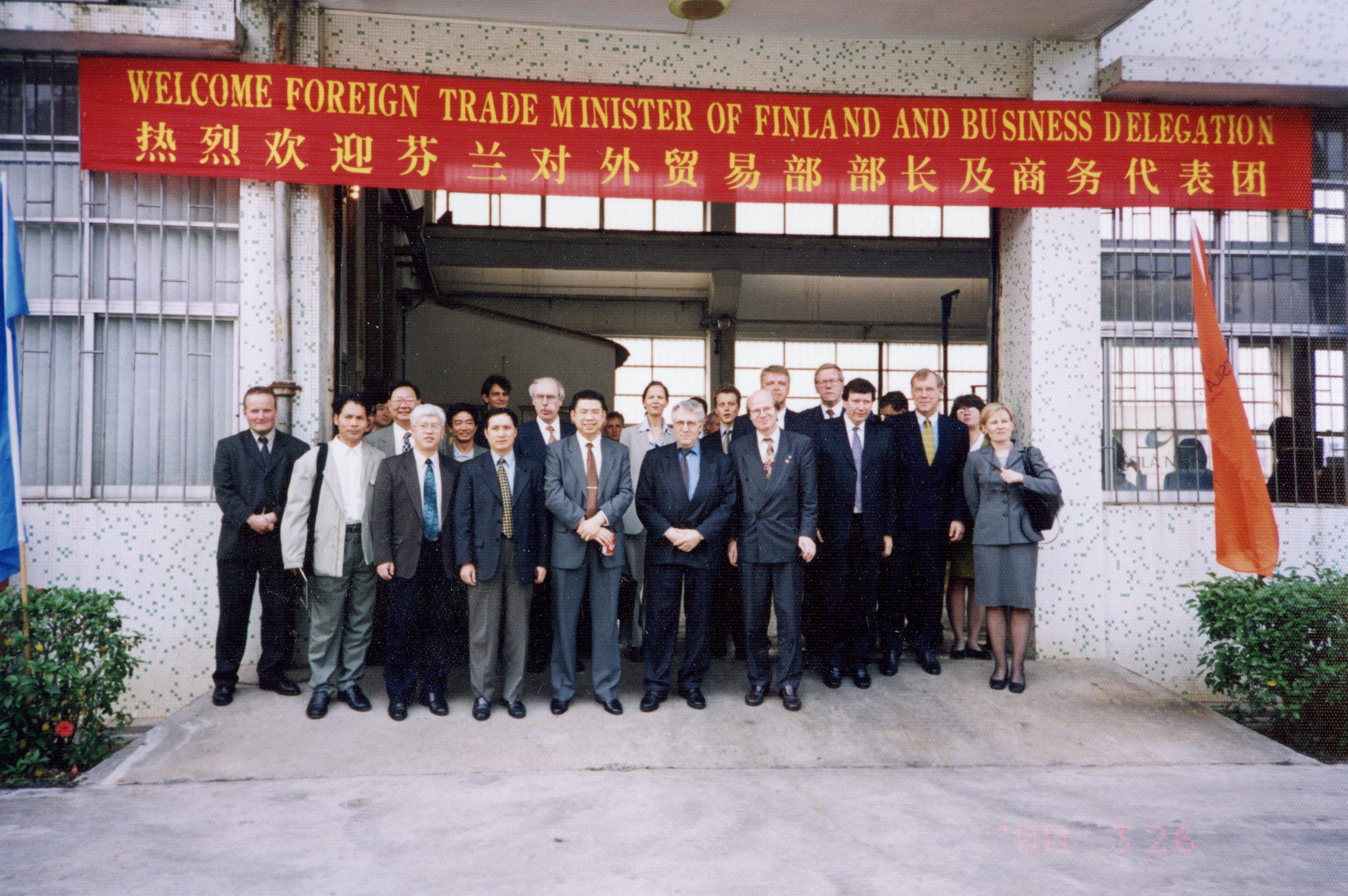

We expand in Asia; Wärtsilä starts several joint ventures in China.

Our customers in both marine and energy industries shift focus towards reducing emissions, and many collaborations are launched to improve sustainability of the industries.

Story: The entire town of Vaasa smelled like burnt bread

Foreign trade minister and business delegation in China.

Remote monitoring of our customers' assets turns into a real business as we start offering Condition Based Maintenance (CBM) as a preventive maintenance service.

We launch our global safety programme targeting zero injuries

Wärtsilä is listed among the 100 most sustainable corporations in the world for the first time. Wärtsilä joins the United Nations’ Global Compact initiative.

Story: What’s the deal with the Irish debt crisis?Wärtsilä delivers the first-ever hybrid power generation system as a battery storage system is installed to complement the existing engine power onboard our customer's vessel.

Launch of the Wärtsilä 31 engine that gets acknowledged by Guinness World Records as the world's most efficient 4-stroke diesel engine.

First engines of a customer are converted to run on methanol.

To lead the energy industry towards a 100% renewable energy future, Wärtsilä focuses on integrations between various energy systems and balancing the intermittency of renewable energy sources. We expand our energy storage capabilities through acquisition.

Clearway solar and storage power plant in Miliani, Hawaii.

In Marine, we make strategic acquisitions to strengthen our energy management and analytics offering. The next year, this materialises as successful tests where we remote control a ship from 8000 km away.

Wärtsilä starts researching Power-to-X as an important technology on the path towards decarbonisation in various industries.

We unveil our purpose – Enabling sustainable societies through innovation in technology and services – that further guides Wärtsilä's efforts towards sustainability. We also accelerate the development of the sustainable fuels methanol, ammonia, and hydrogen.

Wärtsilä takes a leading role in transforming the marine and energy industries; we set goals and reach milestones to decrease the emissions of engine-based power supply in the marine and energy markets, while developing hybrid solutions where energy storage systems are supporting engine and renewables-based power production.

Wärtsilä commits to become carbon-neutral in its own operations and provide a product portfolio ready for zero-carbon fuels by 2030. We launch a major test programme to develop carbon-free power generation solutions with hydrogen and ammonia.

We launch the Wärtsilä 32 methanol engine and the new Wärtsilä 25 engine, the first Wärtsilä engine to run on ammonia.

Wärtsilä’s Sustainable Technology Hub opens in Vaasa, welcoming our partners to accelerate marine and energy decarbonisation together.

Wärtsilä is chosen to power the world's largest battery electric ship.

Wärtsilä is named on the TIME100 Most Influential Companies of 2023 list.

The first Wärtsilä 32 methanol engines are delivered, and there are multiple engine releases for both newbuilds and conversions.

The first engines running on ammonia see daylight, and we run combustion testing on hydrogen blends up to 100%.

We celebrate our 190th anniversary.